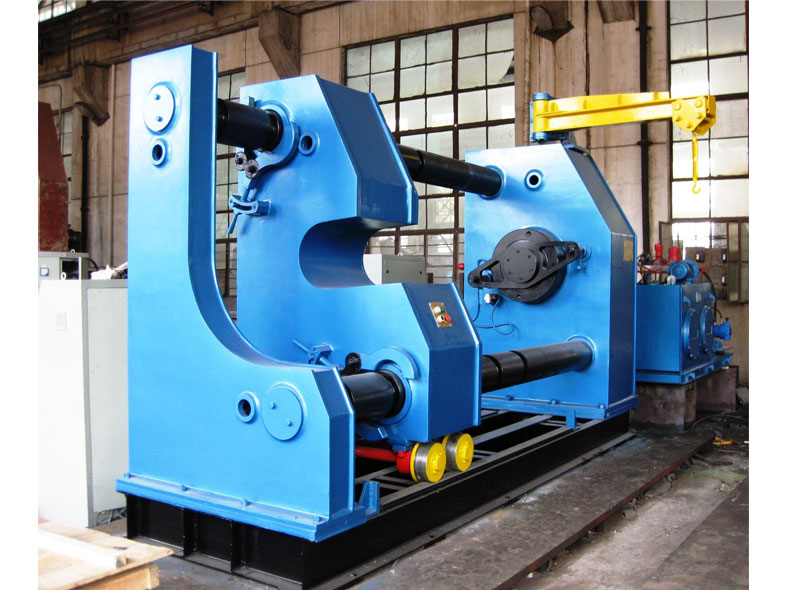

7 Rolls Levelling Machine

The CNC leveler is the first of its kind, and has been widely used in industry. The metal sheet straightening machinehas the characteristics of advanced technology, high leveling accuracy, wide process range, high degree of automation, and reliable and stable work under high strength. During the roll leveling process, the metal plate After a series of alternating bending, the precise control of the pressing amount of each leveling drum through the motor and PLC control eliminates the internal stress and fundamentally solves the different leveling effect caused by the different stresses in each part of the sheet. Ideally, high-precision leveling is achieved.

Compared with other leveling methods, the control system of the plate leveling machinehas the functions of storing, recalling, and editing process and equipment parameters, and has the function of identifying and early warning of misoperation. When in use, on the operating table, the inlet and outlet reductions can be set according to parameters such as plate thickness, plate width, material strength, etc. or the existing parameters in the database, so as to realize the electric adjustment of the work roll and the entry gap, and it can be adjusted manually. And correction.

The Details Of EZHONG 7 Rolls Leveling Machine

- Optimal rational design.

- Use a large number of advanced manufacturing technologies to carry out SOLIDWORKS full three-dimensional digital design, etc.

- Intelligent.

- Control method: PLC+touch screen+button, all working parameters can be set in the man-machine interface, with parameter memory, storage, power-off memory functions.

- Human-machine interconnection.

- The control system of the metal sheet straightening machine has the functions of storing, recalling, editing process and equipment parameters. When using, it can set the inlet and outlet reductions according to the parameters such as plate thickness, plate width, material strength, etc., and realize automatic adjustment.

- Automatic adjustment device for the opening of the metal sheet straightener.

- Before the plate enters the leveling machine, the plate thickness, width, and material are measured by scanning the plate information processing unit, and the signal is transmitted to the electrical control cabinet. The opening amount calculation is automatically performed, and the opening amount of the metal sheet straightener is adjusted. The value is confirmed after correction. Make adjustments again.

High degree of automation, the system inputs parameters such as plate thickness, plate width, strength, etc., and the numerical control system automatically calculates the reduction amount to complete the adjustment of the leveling reduction process parameters, which is convenient and fast leveling.

The whole metal sheet straightener adopts integral steel plate welding, which is thick and beautiful, and has good stability.

Simple operation, single person can work independently.

The Application Of 7 Rolls Levelling Machine

The metal sheet straightener is widely used in industry. EZHONG leveling machine has advanced technology, high leveling accuracy, wide process range, high degree of automation, and good working reliability under high strength. The application range of the metal sheet straightener involves aviation, shipbuilding, metallurgy, and instrumentation. Stainless steel products, etc., play an important role in the verticality, parallelism, and appearance of industrial structural parts.

If you want to know more types of roll forming machine second hand, please visit our website.

Send product request

Other supplier products

| 4 Rolls Plate Bending Machine | EZHONG CNC 4 roller plate bending machinehas the function of pre-bending the end of the sheet. This kind of heavy rolling machine has four work rol... | |

| Ship Plate Bending Machine | The marine three rolling machine produced by EZHONG introduces and absorbs the British "smith" technology, and has dual-purpose functions for rolli... | |

| 3 Rolls Plate Bending Machine | EZHONGis located in the ancient city of Wudu - Ezhou City, Hubei Province. It is one of the heavy forging and shaping equipment enterprises designa... | |

| 4 Rolls Plate Bending Machine | EZHONG CNC 4 roll plate rollerplate bending machine has the function of pre-bending the end of the sheet. The machine has four work rolls. The work... | |

| Пресс с горизонтальной осью | Горизонтальный машина пресс– это установочное оборудование для подшипников качения системы железнодорожного транспорта. Его основное назначен... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |