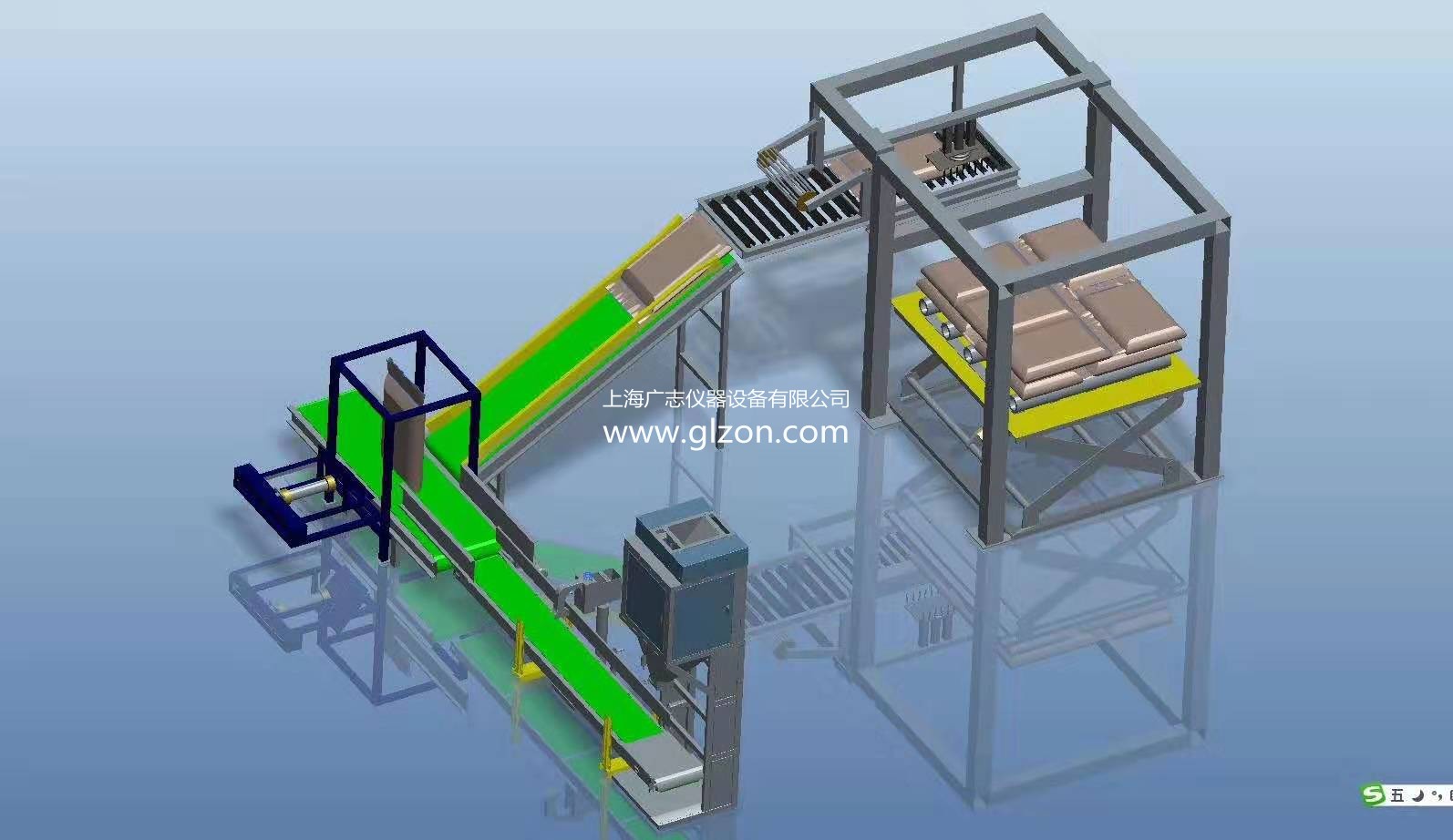

5 liter automatic metering filling machine

5 liter automatic metering filling machine

Product introduction

Semi-automatic liquid filling machine is mainly used for quantitative automatic filling of tinplate barrels and plastic barrels, and is also suitable for automatic fixed filling of liquid materials in food, pharmaceutical, chemical and other industries. Examples: lubricating oil, edible oil, alcohol, disinfectant, printing ink, chemical pigments, coatings, etc.

Product features

This system adopts the weighing filling machine produced by foreign advanced technology, which has high measurement accuracy and is not affected by materials.

2 The feeding valve composed of fast and slow feeding can improve the filling speed and precision.

3 Large measuring range, which can be adjusted arbitrarily within 0.5—50kg.

4. The filling head adopts drip-proof device, and the poured latex paint has no bubbles, and the can opening effect is good.

5 Automatic control of material feeding, equipped with pneumatic clamp cover and pneumatic pressure plate device, the filling volume can store up to 10 formulas, which can be easily switched.

principle of operation

Feeding mode: continuous and stable feeding is required (feeding by feeding pump or hopper under pressure).

The feeding mechanism performs fast and slow feeding by electromagnetic valves through cylinders respectively.

Filling method: ordinary conventional filling and lifting submersible filling (selected when ordering according to needs)

The weighing system consists of weighing bracket, sensor, weighing platform, unpowered roller and frame support and filling system.

Pneumatic control system: control fast and slow feeding valves.

During use, the weighing platform is not allowed to be subjected to additional external forces. The filling nozzle height can be adjusted by the top handwheel.

Introduction to operation

Manually move to the bucket; Manually start; Open the automatic feeding pump and feeding valves; Close the fast feeding valve at the set working point 1; Stop the feeding pump and slow down the feeding valve at the set working point 2; Manually cover and move the barrel zhi gland position (with auxiliary positioning device); Manually capping, and manually moving the barrel after capping; Warehousing. (Upper and lower barrels with stainless steel raceway)

Product parameter

Filling range: 0.5-50L

Filling accuracy: 0.2%

Output: 160~300 times/hour

Electricity source: AC 220v 10%, frequency 50Hz, power 500w.

Use air pressure: 0.4-0.6Mpa, consumption 10m3/h

Material inlet: DN40, (material inlet pressure < 0.6Mpa)

The material in contact with the material is 304 stainless steel.

Other supplier products

All supplier products

Same products