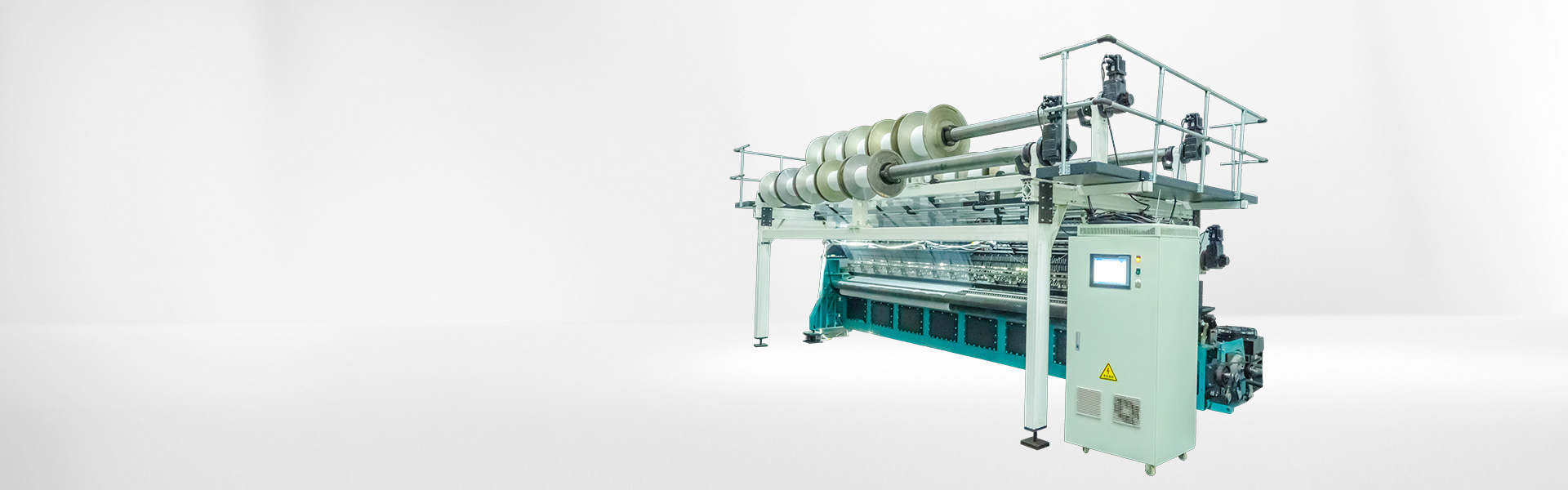

HIGH-SPEED WARP KNITTING MACHINE

After years of R & D and practice, Changzhou runfengyuan Textile Machinery Manufacturing Co., Ltd. has successfully manufactured various models of high speed warp knitting machineand Raschel warp knitting machines. The products have a wide range of changes, high production efficiency and simple operation and maintenance, which can meet different needs and fabric structures. The equipment adopts a new crankshaft connecting rod mechanism optimized by a computer, which reduces the deformation and vibration of parts. The needle bed adopts carbon fibre, which has the advantages of being lightweight, small temperature change and strong rigidity. It is very suitable for high-speed warp knitting machines. All beam shafts adopt a computer-controlled EBC let off mechanism, which can produce pattern tissue with different let off speeds, and the same tissue can have different pattern effects and different densities. The comb bar adopts an integrated mechanism, which is convenient for installation, and the structure tends to be more reasonable. Using EAC electronic take up and winding system, high-quality grey cloth with a uniform coil structure can be woven.

THE DIFFERENCE BETWEEN TRICOT WARP KNITTING MACHINE AND RASCHEL WARP KNITTING MACHINE

The included angle between cloth surface and knitting needle of Tricot warp knitting machineis about 100 degrees; The beam shaft is located at the rear of the machine; The number of bars is less; machine speed fast.

The included angle between the cloth surface of the Raschel warp knitting machine and the knitting needle is about 170 degrees; There must be cloth take up device; The beam shaft is located on the upper part of the machine. There are more bars.

THE DIFFERENCE BETWEEN WARP KNITTED FABRIC AND WEFT KNITTED FABRIC

For the distinction between warp knitted and weft knitted fabrics, it is most intuitive to see from their fabric material structure.

Due to their different weaving methods, the texture of warp knitted cloth extends longitudinally, while the texture of weft knitted cloth extends laterally. Therefore, warp and weft knitted cloth is named.

There are many warp knitting machine manufacturers, but we are one of the best choices for you.

Send product request

Other supplier products

| CURTAIN LACE MACHINE | Run Feng Yuan Curtain Lace Machineare raschel machines with fall plates that produce curtains, outwear and tablecloths with different jacquard patt... | |

| HIGH-SPEED WARP KNITTING MACHINE | After years of R & D and practice, Changzhou runfengyuan Textile Machinery Manufacturing Co., Ltd. has successfully manufactured various models... | |

| JACQUARD CURTAIN WARP KNITTING MACHINE | Raschel curtain machine with Jacquard is suitable for different kinds of curtain, tablecloth with different kinds of Jacquard pattern design. Here ... | |

| HIGH-SPEED WARP KNITTING MACHINE | Tricot Warp Knitting Machine for Sale After years of R & D and practice, Changzhou runfengyuan Textile Machinery Manufacturing Co., Ltd. has s... | |

| NON-WOVEN INTERLINING STITCH BONDING MACHINE | Non woven textile machinerystrengthens the fastness and toughness of the fabrics. After processing, the fibre mesh structure will become compact an... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |