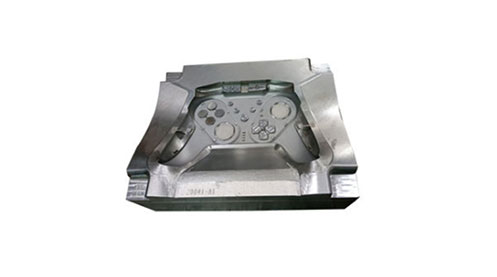

Plastic Enclosure Mold For Electronic Device

In a Lego game, you will hold the laser, sit on the device, and shoot various targets. Since this game is mainly to meet the gaming experience of LEGO fans at a young age, the plastic product shell is required not only to be polished well, but also to be wear-resistant. In addition, because it is a laser electronic housing, it needs to be assembled with electronic components, so the precision requirements for plastic products are relatively high. Finally Green Vitality provide perfect plastic enclosure moldafter first trial.

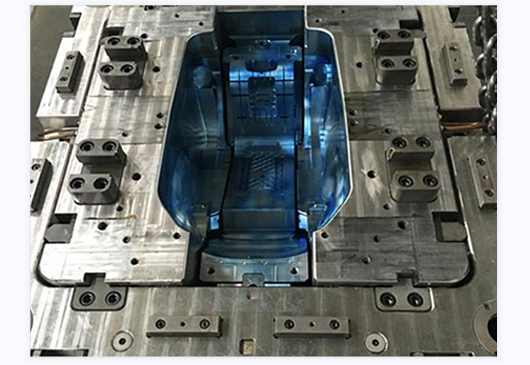

Plastic Injection Mold Steel Requirements For Electronic Enclosure Part

Good polishing performance. Electronic enclosure plastic part injection mold materials usually require good gloss and surface condition. Therefore, the roughness of the cavity surface is required to below. In this way, the surface of the cavity must be surface processed, such as polishing, grinding, etc. Therefore, the selected plastic injection mold steel should not contain rough impurities and pores.

Less affected by heat treatment. In order to improve the hardness and wear resistance, the electronic enclosure plastic injection mold is generally heat-treated, but this treatment should make the size change small. Therefore, it is best to use pre-hardened steel that can be machined.

Good wear resistance. The gloss and accuracy of the surface of the electronic enclosure injection mold material are directly related to the wear resistance of the surface of the injection mold cavity, especially when glass fiber, inorganic fillers, and certain pigments are added to some plastics. Together with the plastic melt, it flows at a high speed in the runner and mold cavity, and the friction on the surface of the cavity is great. If the material is not wear-resistant, it will wear quickly.

Basic Information for Electronic Enclosure Plastic Injection Mold

Plastic Injection Mold Steel Requirements For Electronic Enclosure Part

Good polishing performance. Electronic injection molded enclosuresmaterials usually require good gloss and surface condition. Therefore, the roughness of the cavity surface is required to below. In this way, the surface of the cavity must be surface processed, such as polishing, grinding, etc. Therefore, the selected plastic injection mold steel should not contain rough impurities and pores.

Less affected by heat treatment. In order to improve the hardness and wear resistance, the electronic enclosure plastic injection mold is generally heat-treated, but this treatment should make the size change small. Therefore, it is best to use pre-hardened steel that can be machined.

Good wear resistance. The gloss and accuracy of the surface of the electronic enclosure injection mold material are directly related to the wear resistance of the surface of the injection mold cavity, especially when glass fiber, inorganic fillers, and certain pigments are added to some plastics. Together with the plastic melt, it flows at a high speed in the runner and mold cavity, and the friction on the surface of the cavity is great. If the material is not wear-resistant, it will wear quickly.

Features For Plastic Electronic Enclosure Part

The enclosure of electronic products is one of the commonly used plastic products. People not only have requirements for the function of the finished product but also attach great importance to the material of the shell. The high-quality electronic plastic shell not only has a good appearance but also can effectively extend the service life of the product. So, what are the characteristics of electronic enclosures?

At present, the plastic shells on the market have various styles and complete sizes, but their materials are very different. Most of the electronic enclosures are made of high-quality flame-retardant and fire-retardant ABS materials.

Flame-retardant and fire-retardant ABS materials have excellent impact resistance, heat resistance, low-temperature resistance, chemical resistance, and electrical properties. It also has the characteristics of easy processing, stable product dimensions, and good surface gloss. It is easy to paint, color, secondary processing such as metal spraying, electroplating, welding, hot pressing, and bonding can also be performed on the surface.

In the production of ABS plastic and then adding fire retardant, the electronics enclosure produced not only has the advantages of ABS material but also makes the product have fire resistance.

Green Vitality Industry is a professional injection molding supplierin various industries since 1993. We provide car bumper injection moulding,injection mouldingand etc. Want to know more, contact us.

Send product request

Other supplier products

| Plastic Gear Mold | Injection molded plastic gearsis one of the most widely used transmission mechanisms in the field of instruments & meters, timers, reducers, ca... | |

| Game Controller Mold | To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time wil... | |

| Electronics Mold | Consumer electronics is very popular in our daily life. It consists of many different plastic parts, pcb boards, wires, battery and some metal part... | |

| Auto Part Mold | With the vigorous development of the automotive industry, plastic auto part mold is also developing rapidly. 90% of auto parts are produced by inje... | |

| Home Appliance Mould | GV Mold has rich experience in home appliance molds (such as television, refrigerators, fans, washing machines, air conditioners, and various smart... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |