Plastic Enclosure Mold For Electronic Device

In a Lego game, you will hold the laser, sit on the device, and shoot various targets. Since this game is mainly to meet the gaming experience of LEGO fans at a young age, the plastic product shell is required not only to be polished well, but also to be wear-resistant. In addition, because it is a laser electronic housing, it needs to be assembled with electronic components, so the precision requirements for plastic products are relatively high. Finally Green Vitality provide perfect plastic enclosure moldafter first trial.

Plastic Injection Mold Steel Requirements For Electronic Enclosure Part

Good polishing performance. Electronic enclosure plastic part injection mold materials usually require good gloss and surface condition. Therefore, the roughness of the cavity surface is required to below. In this way, the surface of the cavity must be surface processed, such as polishing, grinding, etc. Therefore, the selected plastic injection mold steel should not contain rough impurities and pores.

Less affected by heat treatment. In order to improve the hardness and wear resistance, the electronic enclosure plastic injection mold is generally heat-treated, but this treatment should make the size change small. Therefore, it is best to use pre-hardened steel that can be machined.

Good wear resistance. The gloss and accuracy of the surface of the electronic enclosure injection mold material are directly related to the wear resistance of the surface of the injection mold cavity, especially when glass fiber, inorganic fillers, and certain pigments are added to some plastics. Together with the plastic melt, it flows at a high speed in the runner and mold cavity, and the friction on the surface of the cavity is great. If the material is not wear-resistant, it will wear quickly.

Basic Information for Electronic Enclosure Plastic Injection Mold

Plastic Injection Mold Steel Requirements For Electronic Enclosure Part

Good polishing performance. Electronic injection molded enclosuresmaterials usually require good gloss and surface condition. Therefore, the roughness of the cavity surface is required to below. In this way, the surface of the cavity must be surface processed, such as polishing, grinding, etc. Therefore, the selected plastic injection mold steel should not contain rough impurities and pores.

Less affected by heat treatment. In order to improve the hardness and wear resistance, the electronic enclosure plastic injection mold is generally heat-treated, but this treatment should make the size change small. Therefore, it is best to use pre-hardened steel that can be machined.

Good wear resistance. The gloss and accuracy of the surface of the electronic enclosure injection mold material are directly related to the wear resistance of the surface of the injection mold cavity, especially when glass fiber, inorganic fillers, and certain pigments are added to some plastics. Together with the plastic melt, it flows at a high speed in the runner and mold cavity, and the friction on the surface of the cavity is great. If the material is not wear-resistant, it will wear quickly.

Features For Plastic Electronic Enclosure Part

The enclosure of electronic products is one of the commonly used plastic products. People not only have requirements for the function of the finished product but also attach great importance to the material of the shell. The high-quality electronic plastic shell not only has a good appearance but also can effectively extend the service life of the product. So, what are the characteristics of electronic enclosures?

At present, the plastic shells on the market have various styles and complete sizes, but their materials are very different. Most of the electronic enclosures are made of high-quality flame-retardant and fire-retardant ABS materials.

Flame-retardant and fire-retardant ABS materials have excellent impact resistance, heat resistance, low-temperature resistance, chemical resistance, and electrical properties. It also has the characteristics of easy processing, stable product dimensions, and good surface gloss. It is easy to paint, color, secondary processing such as metal spraying, electroplating, welding, hot pressing, and bonding can also be performed on the surface.

In the production of ABS plastic and then adding fire retardant, the electronics enclosure produced not only has the advantages of ABS material but also makes the product have fire resistance.

Green Vitality Industry is a professional injection molding supplierin various industries since 1993. We provide car bumper injection moulding,injection mouldingand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

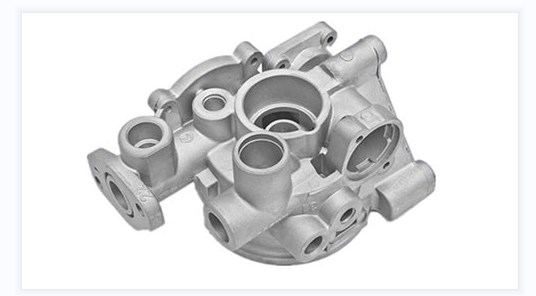

| Aluminum Die Casting Mold | Aluminum High Pressure Die Casting Mold When working at high or low temperatures, they also maintain good mechanical properties and have good co... | |

| Plastic Enclosure Mold For Electronic Device | In a Lego game, you will hold the laser, sit on the device, and shoot various targets. Since this game is mainly to meet the gaming experience of L... | |

| Soap Box Mold | Plastic soap is also made by plastic injection mold, as it need dimensional stability, good apperance and good color performance, so we have to cho... | |

| Auto Bumper Mould | Auto Bumper Mould The front and rear bumpers of the car are made of plastic, which not only maintains the protection function, but also has the ch... | |

| Automotive Air Grille Mold | Automotive Air Grille Mold The car grille is a mesh part with a grid in the front part of the car. The front grille of the vehicle is located betw... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |