Vertical Centrifuge

The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm, the rotor body (including the blade), transmission, body, lubrication system, etc.

Application of Vertical Centrifuge Machine

The vertical centrifugeis fit for material dehydration, generally used for coal, salt and other materials. Our coal centrifuge has helped a lot of customers with their industrial projects.

Working Principle of Vertical Centrifuge Machine

Wet materials are feed into the mouth of industrial centrifugemachine, then are accelerated by the rotated distribution cone and move rapidly towards the space between screen and rotor. With the centrifugal force, the smaller particles of material get closed to the screen surface, liquid and part of the particle size of less than 0.5 mm of material get across the material space and screen gap, then are thrown out of the screen, the larger particles of materials soon slipped into spiral nesting mouth along the screw blade with the action of gravity and centrifugal force fine material attached to the screen surface are discharged by the scraper centrifuge through blade action, while the liquid through the screen and fine materials are thrown into the water tank then outflow through the drain, so as to achieve a solid-liquid separation.

Installation and Testing of Vertical Centrifuge Machine

When the centrifuge is assembled completely in the manufactory, the test should be carried out in air operations. It should be sent out to the users in the form of machine after it is up to the requirements, the users can directly follow the steps to install the equipment when they get receipt of it.

1) Check whether the basis of surface is level, if it is uneven, adjust the leveling pad. Check the ground pin-hole size and pore size of the centre. Check whether the basis of elevation to meet the requirements.

2) Mount the shock absorber to the ground pin holes, install the nut first but not tightened until the machine is in the right place, then solid-tight.

3) Hoisting the machine in the place, tighten anchor bolts, tighten the upper pairs of nuts before the measurement with the caliper pad diameter, it is required that the diameter of compact size should be increased 2~3mm than the first fasten one.

1) Checked before testing items

2) Commissioning and inspection of the project

Meet the above requirements, follow these steps, and start running in the air for 8 hours.

3) Loading Test

When all functioning of the machine working in the air is normal, then gradually feeding at the same time pay attention to the functioning of the device, while there is no abnormal phenomenon, the handling capacity can be increased to 150~200t/h, the handling capacity of the material easily dehydrated can be larger, difficult to dehydration material handling capacity can be smaller. Add enough materials, it may take the measurement as the following items, when all meet the requirements, the equipment can be put into use.

Centrifuge normal maintenance plays an important role in preventing accidents and injury in the weight of link components in the device’s using, and the systems should be required to perform.

Vertical Centrifuge Application

CIC Customized and Intelligent Equipment in Mining & Minerals Industries

Mining & Minerals

There are many heavy equipment dealersin China, but we are one of the best choices for you.

Send product request

Other supplier products

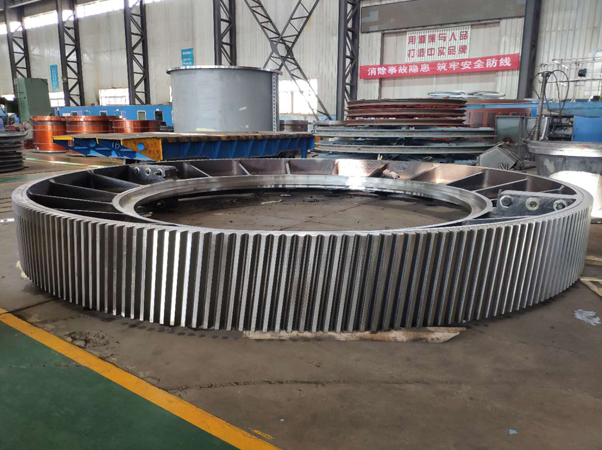

| Girth Gear | CIC is the casting & forging center in central-south China, possessing a 50t electric arc furnace, 60t LF ladle refining furnace, and 60t VD/VO... | |

| Industrial Rotary Dryer Machine | CIC have accumulated decades of experience in the production of industrial sludge dryermachine, through continuous improvement, research and develo... | |

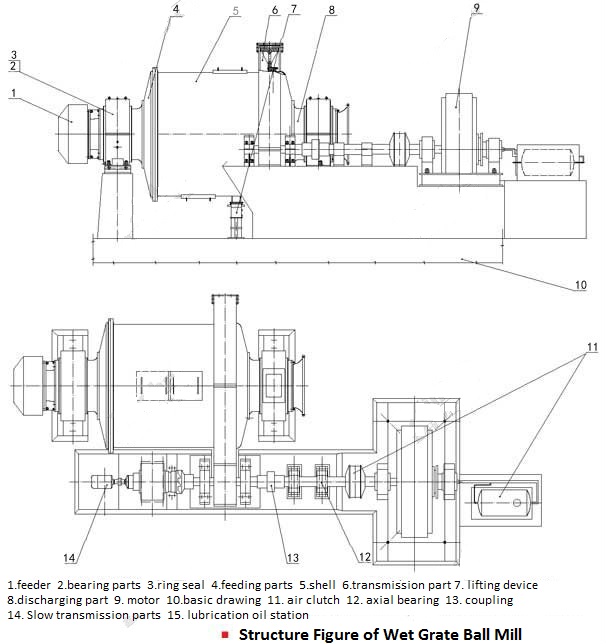

| Wet Grid Ball Mill | Wet ball mill is a kind of energy-saving industrial ball mill which adopts rolling bearings and has high efficiency. Wet grid mining ball mill proc... | |

| Vertical Centrifuge | The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm , the rotor body (including the blade), transmiss... | |

| Industrial Centrifuge Machine | Centrifugal concentrator is a kind of equipment for gravity separation of ore particles in a centrifugal force field, which is one of the high-effi... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |