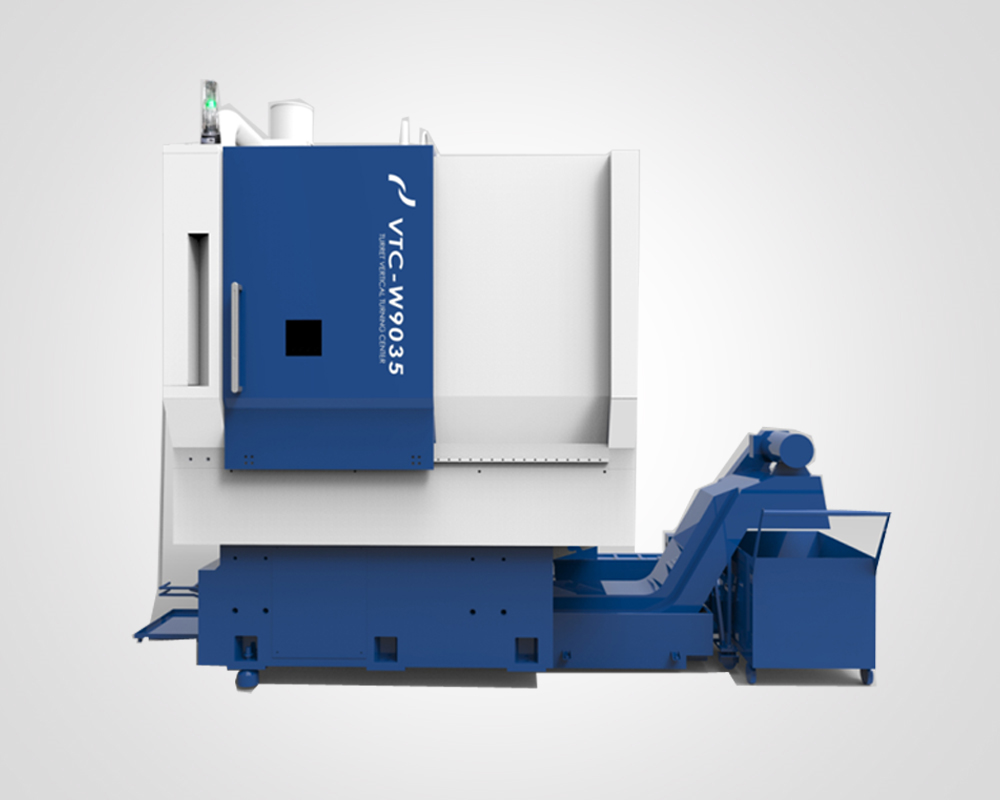

PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE

The X/Y/Z servo axis adopts the servo motor direct connected precision planetary reducer to drive the large-diameter, high-precision double nut preloaded ball screw. The machine tool guide rail adopts the roller linear rolling guide rail pair. The X-axis and Z-axis adopt the three guide rail design to ensure the high bearing and high stability of the machine tool.

FEATURES OF PBC SERIES PLANER TYPE MILLING MACHINEAND BORING MACHINE

X/Z axis adopts three imported heavy-duty roller linear guide rails, imported ball screw pair, fully closed telescopic shield, and fully closed-loop control. Two-speed reduction gearbox plus one-stage gear is adopted for deceleration, with the maximum speed of 2000, the maximum output torque of 2000Nm, the maximum reduction ratio of 1:14.46, and the minimum reduction ratio of 1:2.63. The spindle bearing adopts FAG special bearing, which is cooled and lubricated by thin oil circulation, so as to ensure the long-term and high-precision operation of the spindle.

HOW DOES PBC SERIES PLANER TYPE MILLILING AND PLANER TYPE HORIZONTAL BORING MACHINEWORK?

It is suitable for processing various kinds of basic large parts, plates, discs, shell parts, molds and other parts with large and medium size, large and medium weight. After one-time workpiece clamping, a variety of processing such as milling, drilling, boring and reaming can be continuously completed with the characteristics of automatically, efficiently and accurately.

WORKING PRINCIPLE OF PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE

The machine tool is column movable, with a single column, transverse base, and side hanging spindle box layout, and is equipped with a tool and workpiece cooling system, The transverse (x-axis) feeding movement of the machine tool is realized by the transverse movement of the worktable along the bed, the longitudinal (Z-axis) feeding movement of the machine tool is realized by the longitudinal movement of the spindle box and column along the longitudinal base, the vertical (Y-axis) movement of the machine tool is realized by the up and down movement of the spindle box along the column, and the longitudinal movement of the boring bar is realized by the movement of the boring bar in the spindle box sleeve (W-axis), the worktable can realize 360 ° continuous rotation of B coordinate on the sliding saddle (with four-point precise positioning function), the arbitrary indexing positioning function of the rotary table is realized through disc spring clamping and hydraulic loosening.

PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE SPECIFICATION

PBC1120/PBC1330/40

|

Model |

Unit |

PBC1120 |

||

|

Boring spindle |

Diameter |

mm |

110 |

|

|

Taper type |

BT50 |

|||

|

Spindle motor |

kW |

|||

|

Max torque |

Nm |

2000 |

||

|

Max speed |

rpm |

2500 |

||

|

CNC rotary table |

Worktable |

m |

||

|

Positioning accuracy |

" |

±6 |

±6 |

|

|

Repeatability |

" |

±3 |

±3 |

|

|

Load capacity |

Kg |

8000 |

100000 |

|

|

Travel distance |

X-axis |

mm |

2000 |

|

|

Y-axis |

mm |

1600 |

||

|

Z-axis |

mm |

1200 |

||

|

W axis |

mm |

600 |

||

|

Feed speed |

Transverse (X) |

mm/min |

2-6000 |

|

|

Vertical (Y) |

mm/min |

2-6000 |

||

|

Longitudinal (Z) |

mm/min |

2-6000 |

||

|

Axial (W) |

mm/min |

2-2000 |

||

|

Rapid traverse |

Transverse (X) |

mm/min |

10000 |

|

|

Vertical (Y) |

mm/min |

10000 |

||

|

Longitudinal (Z) |

mm/min |

10000 |

||

|

Axial (W) |

mm/min |

3000 |

||

As one of the cnc machining center manufacturers, we provide cnc processing center, horizontal turning lathe, vertical cnc machineand etc. For more information, please feel free to contact us!

Send product request

Other supplier products

| HBC SERIES CNC HORIZONTAL BORING AND MILLING CENTER FOR SALE | HBC Series is our CNC horizontal boring machine. According to the different sizes, we have HBC1116 CNC horizontal boring machine and HBC1316 CNC ho... | |

| CNC Milling and Boring Machine | The maximal rotation of spindle can reach 2500rpm/min It can meet the large-torque requirement during the rough machiningand the high rotation... | |

| UNIVERSAL HORIZONTAL LATHE | The machine tool adopts the mainstream oblique bed structure of Europe, America, and Japan, with integrated electromechanical, hydraulic, and gas d... | |

| PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE | The X/Y/Z servo axis adopts the servo motor direct connected precision planetary reducer to drive the large-diameter, high-precision double nut pre... | |

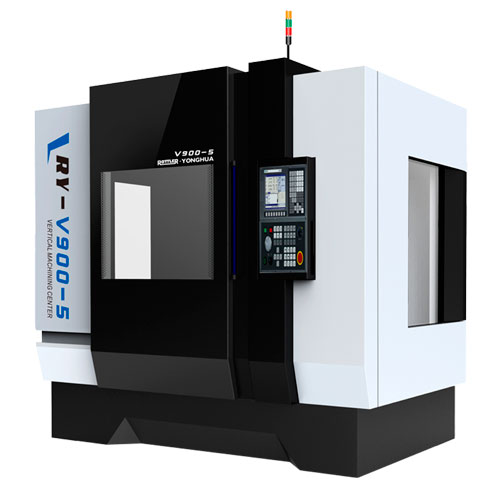

| 5 AXIS VERTICAL MACHINING CENTER | Vertical type five axis vmc machineis a high-end 5-axis linkage machine tool that developed after taking in the German advanced technology. Its fea... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |