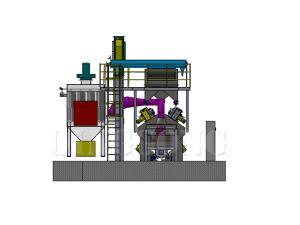

H BEAM SHOT BLASTING MACHINE

Hbeam shot blasting machineis the most efficient and the most effective process to remove all forms of rust and corrosion materials from h beams prior to painting or coating.

It is more efficient than steel beam china shot blasting machine, steel bar shot blasting machine and sandblasting beamsshot blasting machine. In the blasting process, use the roller conveyor system which is controlled by frequency converter to transmit h beams into the blast chamber, blast wheel throw steel shot and hit the surface of h beams, make oxide layer and dirt rust wore off quickly, after the h beam blasting, sent out from the other side.

Composition of H beam roller shot blasting machine: roller conveyor system, blasting chamber, abrasive recovery system, dust collector, electric control system and others.

The technical data is not binding and may be subject to change. Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

sandblasting steel beams 3d drawings

Abrasive recovery system:

H beams shot blasting machine system use a longitudinal screw conveyor to reclaim the used blasting media and contaminants into the crosswise screw conveyor, then into the bucket elevator and abrasive residue separator, and then the cleaned abrasive get into the storage hopper to recycle, the residual will get out of the recycling system from the air wash cleaner system.

Screw conveyor

The material of the screw conveyor is 16Mn, strong wear resistance.;

Screw conveyor is first welding and then processing, to ensure the concentricity of the screw conveyor.

screw conveyor two ends adopt labyrinth type superposition seal, high self-sealing performance, resistance to high pressure.

On the below of the screw conveyor has s manual emptying valve. If the screw conveyor is blocked, it can open the emptying valve to clear the abrasive that to run the machine as soon as possible.

Abrasive residue separator

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensure high quality blasted surface and minimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdown rate.

Critical to achieving this efficiency is the effectiveness of the abrasive recycling plant. Poorly designed or manufactured abrasive recycling systems will not correctly recycle the abrasive and are unable to maintain the correct abrasive working mix.

Our patented abrasive separator consists of an extended rotary separator drum that will totally remove all big clumps including big wast, scrap and paint chips etc. The abrasive is then fed through a gravity air wash separator where all dust, degraded abrasive and waste is drawn out of the good abrasive by an air current.

Only good, correctly sized abrasive is fed back to the abrasive storage hopper and blast pots for recycling.

Our patented abrasive cleaner ensures maximum recycling rates of the abrasive and high-quality surface finishing is achieved.

Send product request

Other supplier products

| BARREL TYPE SHOT BLASTING MACHINE | The Barrel Blast Machineline provides outstanding performance and reliability. Designed for foundry, forge and heat treat requirements. The Barr... | |

| ROTARY TABLE SHOT BLASTING MACHINE Free Quote | Rotary shot blasting machineor table type shot blasting machineis suitable for various shapes and dimensions, casts, forged parts, pressed parts, s... | |

| ANCHOR CHAIN SHOT BLASTING MACHINE | The working principle for anchor chain shot-blasting machine is mainly by numerous high speed abrasive flow projection to the anchor chain surface,... | |

| FLOOR SHOT BLASTER | Floor shot blasteris a kind of concrete floor shot blasting equipment, steel plates. The floor concrete blastercan clean up the floatation and i... | |

| PRESERVATION LINES Free Quote | On the preservation line, sheets and profiles are thoroughly blast cleaned and provided with a temporary corrosion protection coating. Along with... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |