Twin-Screw Recycled Plastic Extrusion Molding Machine

Due to the complex composition of the bottom material after cleaning of waste plastics, including PE, PP, PA, PS, ABS, etc., these plastics must be mixed and dispersed well; plasticized well, and the interface should be modified, so as to obtain Good product quality. For this reason, co-rotating parallel twin-screw extrusion is preferred.

The advantages of co-rotating parallel twin-screw, good mixing and plasticizing, and good dispersion, can modify the plastic, so that the compatibility is greatly improved, so that different plastics can be well combined, thereby improving the strength of the product.

Specifications of Twin-Screw Recycled Plastic Extrusion Molding Machine

|

Type |

Frequency (pcs/min) |

Pressure(T) |

Output (KG/H) |

Total Power (KW) |

Double screw diameter(mm) |

Single screw diameter(mm) |

Products size |

Outside dimension (L*W*H) |

Weight (Ton) |

|

GWJZPD-1 |

2-3 |

1500 |

350-450 |

250 |

75 |

150 |

1500*1300 |

10000*5400*6000 |

85 |

|

GWJZPD-2 |

2000 |

450-550 |

400 |

90 |

165 |

1600*1400 |

14000*5500*7000 |

120 |

Features of twin screw plastic extruder

Due to the complex composition of the bottom material after cleaning of was te plastics, including PE, PP, PA, PS, ABS, etc., these plastics must be mixed and dispersed well; plasticized well, and the interface should be modified, so as to obtain Good product quality. For this reason, co-rotating parallel twin-screw extrusion is preferred.

The advantages of co-rotating parallel twin-screw, good mixing and plasticizing, good dispersion, can modify the plastic, so that the compatibility is greatly improved, so that different plastics can be well combined, thereby improving the strength of the product.

Application of twin screw compounding machine

The composition of the sinking material after cleaning is more complicated, because the sinking bottom and most of them are engineering plastics, such as: ABS, PS, PA and some PE, PP, etc., their process temperature is different, use If the dispersion is not good in the process, it will affect the quality of the product; in addition, due to the different chemical properties of the materials, the compatibility is poor, so the materials should be modified.

If waste spinning is to be used, first granulate the waste spinning, and then add the waste spinning particles, plastic particles and additives to the co-rotating flat twin-screw through a metering feeder for mixing, dispersing, and modification. The production of the product is realized by extruding the single screw into the material storage device.

Fishing net materials include PE, PP, and PA. To make good products, PE, PP, and PA must be evenly dispersed in order to receive good results.

RELATED MIXED PLASTIC RECYCLING EXTRUSION & INJECTION MOLDING MACHINE

One-Step Fabric Recycling Machine

Single-Station Two-Step Extrusion Molding Machine

Double-Station Two-Step Recycled Plastic Extrusion Molding Machine

As a professional plastic recycling machine factory, we provide plastic recycling machine in china, plastic recycling machine for sale, ps recycling machine, twin screw extruder for plastic, plastic twin screw extruder, co-rotating twin screw plastic extruder, co-rotating twin screw extruder for recycling waste plastic, waste plastic bottle recycling machine, etc. Want to know more, contact us.

Send product request

Other supplier products

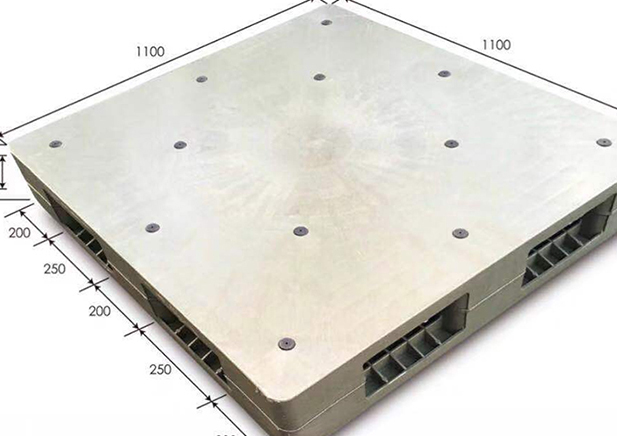

| Plastic Pallet Welding Machine | Hot plate pallet welding machinemade by our plastic pallet welding machinemanufacturer is a kind of machine widely used for welding various plastic... | |

| Mulch And Greenhouse PE Film Washing Machine | According to the statistics of China Urban Environmental Sanitation Association, my country produces nearly 1 billion tons of garbage every year, i... | |

| Pet Bottle Washing Recycling Machine | The main production lines of pet bottle recycling washing machineare conveyor belt, off-label machine, sorting table, crusher, hot water steamer, s... | |

| Plastic Moulds | Double-sided welding plastic pallet mold: First press out two half-sided nine-pin pallets, and then weld them together by a welding machine. After ... | |

| Pet Bottle Washing Recycling Machine | The main production lines of pet flakes friction washerare conveyor belt, off-label machine, sorting table, crusher, hot water steamer, screw eleva... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |