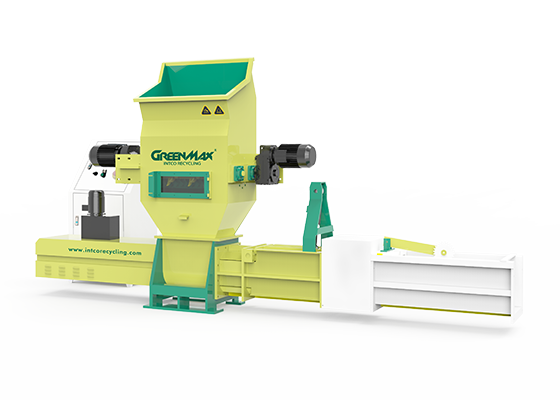

Mixed Plastic Recycling Extrusion & Injection Molding Machine

The equipment we have developed includes: one-step extrusion molding equipment for mixed waste plastic films; two-step extrusion molding equipment for mixed waste plastics; co-directional flat one-step extrusion molding equipment; single-station and double-station extrusion molding equipment for higher production efficiency.

Plastic recycling molding machinesolves the worldwide problem that mixed plastics waste is difficult to be reused, and truly enables mixed waste plastics to achieve green recycling and high-value utilization. We can also formulate sustainable anti-expansion solutions and tailor-made equipment according to customers' raw materials and requirements.

Types of Mixed Plastic Recycling Extrusion & Injection Molding Machine

Double-Station One-Step Recycling Plastic Extrusion Molding Machine

The fully automatic one-step film extrusion molding equipment is our company's patented product.

The Difference Between Injection Molding And Extrusion Molding

1 / 2

The difference between extrusion molding and injection molding

Extrusion molding: The material is double-mixed, dispersed and plasticized through a special co-rotating cone, and the plasticized plastic is extruded into the storage tank through reversing. When the required amount is reached, the plastic is extruded into the mold. When the mold has a certain space, after the material is injected, it is pressed and cooled to make the products we need.

Injection molding process

This production method is to directly inject the plastic into a fixed mold after plasticizing, and the mold is fixed and then cooled to make the product we need. For example: trays, plastic manhole covers, plastic flower pots, etc.

How Does Mixed Plastic Recycling Extrusion & Injection Molding Machine Work?

Plastic pollution has become one of the most pressing environmental concerns, as the rapidly growing production of single-use plastic products outstrips the world's ability to deal with them. Plastic pollution is most pronounced in developing countries in Asia and Africa, where waste collection systems are often inefficient or non-existent. But developed countries, especially those with low recycling rates, also struggle to properly collect waste plastic. To this end, we have developed mixed waste plastic cleaning equipment and granulation equipment for processing, and then use "mixed waste plastic extrusion molding equipment" to make the products we need, trays, manhole covers, flower pots and other products.

Through the design of the barrel and the screw, the main difficulties of mixing, dispersing, plasticizing and mixing mixed waste plastics can be solved;

Through technical research, the measurement problem of products has been solved;

Through the improvement of the storage system, the problem of insufficient injection force has been solved;

Realize intelligence through automatic design.

As a professional plastic recycling machine factory, we provide plastic recycling machine in china, waste plastic recycling machine, extruding recycled plastic, extrusion recycling, recycled plastic molding machine, recycled plastic extrusion machine, waste plastic extrusion machine, recycled plastic extrusion, etc. Want to know more, contact us.

Send product request

Other supplier products

| Twin-Screw Recycled Plastic Extrusion Molding Machine | Due to the complex composition of the bottom material after cleaning of waste plastics, including PE, PP, PA, PS, ABS, etc., these plastics must be... | |

| Rigid Waste Plastic Washing Machine | For the PE category, it mainly includes milk bottles, food packaging boxes, laundry detergents, daily chemical products bottles, edible oil drums a... | |

| Single Shaft Plastic Waste Shredder | Plastic uniaxial shredder is mainly used for shredding hard plastics, such as: machine head material, trays, shredding of daily miscellaneous hard ... | |

| Mixed Plastic Recycling Extrusion & Injection Molding Machine | The equipment we have developed includes: one-step extrusion molding equipment for mixed waste plastic films; two-step extrusion molding equipment ... | |

| Plastic Pallet Crushing and Shredding Machine | Pallet Crusher for Sale The waste plastic pallet shredding-shredding machine is a supporting product specially developed for pallet shredding, cre... |

Same products

| PET bottle recycling machine And Squeezer POSEIDON C900 | Seller: Intco Recycling GREENMAX | PET bottle recycling machinePoseidon series specializes in de-watering and compacting beverage bo... | |

| GREENMAX PET bottle recycling machine P-C350 | Seller: Intco Recycling GREENMAX | PET bottle recycling machinePoseidon series specializes in de-watering and compacting beverage bo... | |

| PET bottle recycling machine And Squeezer POSEIDON C200 | Seller: Intco Recycling GREENMAX | PET bottle recycling machine Poseidon series specializes in de-watering and compacting beverage b... | |

| GreenMax Foam Compactor Z-C100 | Seller: Intco Recycling GREENMAX | GreenMax Zeus C100 foam compactor isspecialized in waste foam recycling by extruding foam based o... | |

| GREENMAX EPS crusher for beads | Seller: Intco Recycling GREENMAX | GREENMAX EPS beads crusher is a recycling equipment, especially for recycling EPS/polystyrene. Di... |