VMC Vertical Milling Machining Center For Sale

Our vmc milling machine types mainly include VMC and VL two series, VMC series include VMC50B vmc milling machine, VMC50C vmc milling machine, VMC60B vmc milling machine, VMC60C vmc milling machine, VMC70B vmc milling machine, VMC70C vmc milling machine.

The structure of vertical machining centers is the cross slide table. It has a large span of the 3-axes linear guideway which is high steady, high rigidity.

The 3-axes full travel is supported by the roller guideway.

The tool magazine is vertically installed on the side of the column that reduces the amount of the overhang of the tool arm which guarantees the rigidity of the tool magazine bracket and the stability of changing tools for a long time.

As a professional vmc machine manufacturing company, the design of our types of vmc machine is that the fixed parts are made from mineral casting and the traveling parts are made of high-strength alloy steel which makes our machining centers have excellent precise retention, fast responsibility, and rapid traveling speed.

TYPES OF VMC MACHINE FOR SALE

VMC-series Vertical Machining Center

VL-series Vertical Machining Center

GV-series Vertical Machining Center

CHINA VERTICAL MACHINING CENTER MANUFACTURER

As one of the most professional China vertical machining center manufacturers, our team of highly skilled engineers and technicians is dedicated to designing and manufacturing reliable and high-performance China vertical machining center that meet the needs of our clients in various industries. We specialize in crafting advanced machinery that is efficient, precise, and configurable to suit different types of workloads. Our goal is to deliver the best possible China CNC vertical machining center solutions to our customers, whether they require standard or customized equipment. We are committed to delivering quality, innovative technologies that help businesses increase productivity and reduce costs. Inquiry cnc vmc for sale.

ADVANTAGES OF VMC MACHINE

To make sure the highest precision, stability, and precision preservation of each machine, we take in new casting material UHPC and build our casting workshop. For the current manufacture of the company, all machine bases and columns are cast by UHPC strictly according to German casting standards.

Better Vibration Absorption

The vibration absorption of UHPC mineral casting is 10 times better than iron casting. Under a large dynamic load, the stability of VMC types machine precision can be guaranteed, while the surface finish quality of the workpiece can also be improved by 20%.

Excellent Thermal Stability

The thermal conductivity of UHPC mineral casting is 1/20 of that of iron casting, the specific heat capacity is 2.1 times that of iron casting. Excellent thermal stability and thermal inertia can effectively control any kind of machine deformation caused by temperature change, the stability of machine precision is further guaranteed.

High Rigidity

The moving parts are welded by high-strength low-alloy steel, the material elasticity modulus is around 1.4 times that of iron casting so that overall rigidity can be improved by more than 30%.

Lighter Weight

Compared to iron casting, the lighter-weight structure can reduce unit weight by 20%-30%, effectively reduce the inertia of moving parts and increase the dynamic response by 10-20%.

Standard tool magazine is configured with 24Tools(30Tools Optional)can increase tool selecting the range, realize fast auto tool change, and further shorten the stand-by time when no cutting.

Auto-lubrication System

The types of VMC machining centers are equipped with an auto-lubrication system that can auto lubricate the Linear Guide Rail, Block, Ball Screw, and Spindle at set time and volume, leaving no dead ends. The CNC machining equipment's dynamic processing accuracy and stability are guaranteed.

Conditioner

The electrical cabinet has an air conditioner, which keeps a constant temperature that guarantees dynamic processing accuracy.

VMC-SERIES VS. VL-SERIES VERTICAL MACHINING CENTER

The VMC and VL are mainly different in the below 4 points:

VERTICAL MACHINING CENTER COMPONENTS

The following is the list of vertical machining center parts.

|

Standard Configuration |

Options |

|

FANUC 0i-MF |

Chain type conveyor and cart |

|

Auto lubrication system |

Two side-chain type back chip conveyor |

|

Air source filtration system |

Spindle temperature control system |

|

Spindle taper air blow |

CTS(coolant through spindle) |

|

Spindle air curtain protection |

Electrical cabinet door opening detection |

|

Workpiece cooling system |

4-axis rotary and tailstock |

|

Integral shield of machine tool |

Electric cabinet air conditioner |

|

Handheld pulse generator |

Door opening detection |

|

Machine tool lighting system |

Chassis chip |

|

Alarm light |

Pneumatic door |

|

Spindle ring spray |

Door interlock |

|

Disk-type ATC-24T |

Tool setter |

|

Communication interface |

Water gun |

|

Gas reservoir |

|

|

Air gun |

VERTICAL MACHINING CENTER FAQS

What is vertical machining centers used for?

Our vertical machining centers designed with integrated electromechanical, good appearance, can perform the precision cutting. It can continuously finish the milling, drilling, boring, reaming, countersinking, tapping. This cnc machining center for sale is suitable for processing the various complex parts of the medium, small-sized box, board, plate, shell. It is widely used in automobile spare parts, valves, construction machinery, IT equipment, Optical Equipment, medical equipment, and the aerospace industry.

What is working principle of vertical machining center?

The 3 axes achieve linear movement by the ball screw rotating driven by the coupling connecting by the servo motor. Four-axis can be optional to make the multi-face processing.

How do you install your machining centers and train the operator?

We can provide online technical support or dispatch our engineer to provide onsite support. We have a subsidiary company in Germany that can also provide technical support.

Send product request

Other supplier products

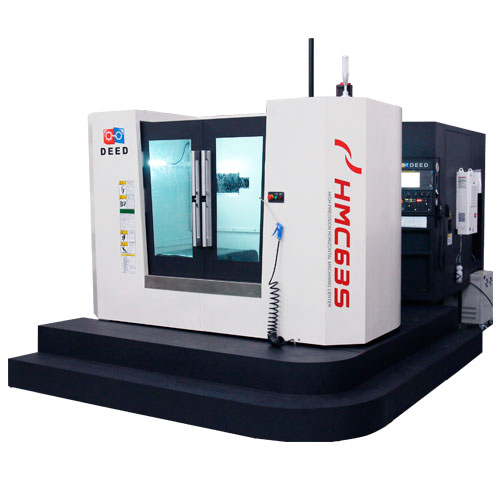

| HMC-S HORIZONTAL MACHINING CENTER WITH PALLET CHANGER | DEED horizontal machining center with pallet changer mainly used for the processing of box, shell, and special-shaped parts in automobiles, motorcy... | |

| VMC Vertical Milling Machining Center For Sale | Our vmc milling machine types mainly include VMC and VL two series, VMC series include VMC50B vmc milling machine, VMC50C vmc milling machine, VMC6... | |

| VMC-SERIES VERTICAL MACHINING CENTER | New VMC-series Vertical Machining Centeris mainly suitable for processing complex parts such as plates, discs, molds, and small shells. The vertica... | |

| HMC-S HORIZONTAL MACHINING CENTER WITH PALLET CHANGER | DEED horizontal machining center with pallet changermainly used for the processing of box, shell, and special-shaped parts in automobiles, motorcyc... | |

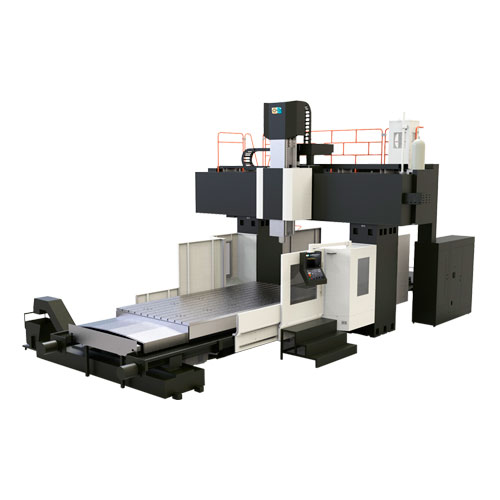

| GL-SERIES GANTRY MACHINING CENTER | Gantry Milling machine GL series has an Excellent high-rigidity structure and Cost-effective full-stroke machining tool. According to different Y-a... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |