Coil-Fed Punching Machine

Thecoil fed punching machinesis widely applied in steel furniture, electrical cabinets, elevator, etc. industries. Which can be combined with laser cutting, panel bender, Robert loading and unloading system, can realize the 24 hours unmanned processing and the electricity consumption only need 1 degree/hour. Thissheet metal slitting machineis the complete solution for coil sheets. Including de-coiling system, levelling system, thick turret punching and slitting system.If you need the higher productivity, less electric consumption and less cost on materials and labors. This is your best choice.

REMCOR coil-sheet fed punching or shearing line is a fully automated punching solution for metallic coils. Which can realize the 24 hours unmanned production. It is capable of handling coils of 300 – 1500 mm in width, up to 9 ton in weight.

Features of Coil-Fed Punching Machine

24 hours unmanned processing, From the de-coiling, feeding, leveling, feeding, thick turret punching, slitting the whole process can be done with our system continuously. Realize the real 24 hours unmanned processing. The traditional processing needs different systems and a numeral labor to handle the machine together with loading and unloading. Different devices have different beats and lead a lot of waste on labors.

Higher productivity, only need to monitor the system, can realize the 24 hours continuous automatic manufacturing. Continous processing from the raw coil material to the final profile, there is no waste of time in loading and blanking compared with traditional forming lines. 2 times faster than traditional technologies.

Higher Flexibility, Multiple combination with standard die bases and diverse die tools, one-to-one correspondence between products and molds. Shorter mold changing time.

More chances for automation, It is available for combining with laser cutting system, panel bender system, and Robert loading and unloading system, which can leave more space for automation. With punching station unworking, and the other station working, it is equivalent to a leveling line, can provide plates for turret punching, single platform laser cutting machines, automatic panel benders, etc.

Parameter Details of Coil-Fed Punching Machine

|

Feeding system |

1000mm/ Precision Ball Screw |

|

Die base |

2 sets of standard thick turret plug-in box molds 4 sets of Remcor standard mold bases |

|

Punch frequency |

200cp/min |

|

Die changing trolley |

2 |

|

Number of servo axes |

8+1+2 |

|

Material width |

300-1000mm |

|

Feed roller |

2sets |

|

Correction roller |

Up 5/Down 4 |

|

Output speed |

16m/min |

|

Coil weight |

7T/8T |

|

Coil inner hole |

φ508mm |

|

Coil outer hole |

φ1300mm |

|

Rack expansion |

Hydraulic |

|

Max thickness |

2mm |

|

Forth |

300KN |

|

Maximum punching |

90*180mm |

|

Number of modules |

There are 8 stations in B and 4 stations in D, which can hold 4 large squares or 8 small squares |

|

Punching accuracy |

±0.1mm |

|

Diagonal accuracy |

±0.5mm |

Coil loading - Trolley - Decoiler

steel sheet slitting line

The Coil-sheet fed system starts with loading. The process can automatically change from one material to another in under 2 minutes. The hydraulic expansion is applied in decoiling station. After the decoiling station, the strip is straightened and the coiling tensions are removed.

Levelling station

sheet slitting line

The levelling station principle is using upper and down rolls to staigthen the strip. After this station the tensions for the strip are removed. The rolls and drive motors will be choosen according to the material thickness. The straightener settings can be imported from the controller system, we also add the manual wheel for the special condition

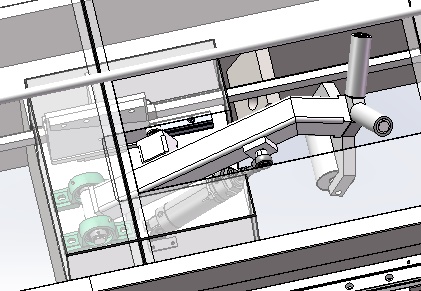

Punching unit

steel coil slitting sheet metalmachine price

The levelling station principle is using upper and down rolls to staigthen the strip. After this station the tensions for the strip are removed. The rolls and drive motors will be choosen according to the material thickness. The straightener settings can be imported from the controller system, we also add the manual wheel for the special condition

FAQ of Coil-Fed Punching Machine

Our metallic coil-sheet feed punching line is widely applied in steel furniture industry, the electric cabinets. the elevator shells, the kitchen and bathroom facilities, etc. Pls kindly share with your profile drawings and material type, width, thickness, weight. We will offer you suitable proposals

Yes and before travelling, pls also kindly share with us your profiles drawings, material type and thickness and weight. We welcome the global business partners to visit us.

Our system Punching is done by tools set in two traversing tool cassettes, with the punching stroke done by a single ram plate. The dies quantity for our punching unit is at least 6 stations more than turret punching. And our system support the customerized square dies. The system starts with the raw coil material, which is different as turret which need to be cut-to-length square sheets that have been processed. The completly efficiency for our system is much higher than turret punch.

If you want to know more about steel coil slitting machine price, please contact us.

As a laser machine distributor, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Sheet Metal Cutting Machine | Machine Used to Cut Sheet Metal Remcor fiber laser cutting machine can help to cut intricate shapes, designs, and small holes for the high quality... | |

| Apollo BK Three-chuck Tube Laser Cutting Machine 1000w-6000w | Remcor Apollo BK series three chuck tube lazer cuttingmachine can cut all types of metal tubes, from mild steel to stainless and also non-ferrous m... | |

| Laser Machine in Construction | Laser cutting and weldingtechnology is applied in construction industires for a wide range of metal materials such as mild steel, stainless steel, ... | |

| Professional Laser Welding Machine | As a laser welding machine company, Remcor offers the professional welding machines which is 3-5 times faster than traditional argon or tig mig wel... | |

| Tube Laser Cutting Machine | Tube Laser Cutting Machine Remcor steel pipe laser cutting machine solutions can certainly meet all of your metal laser steel pipe cutting demands.... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |