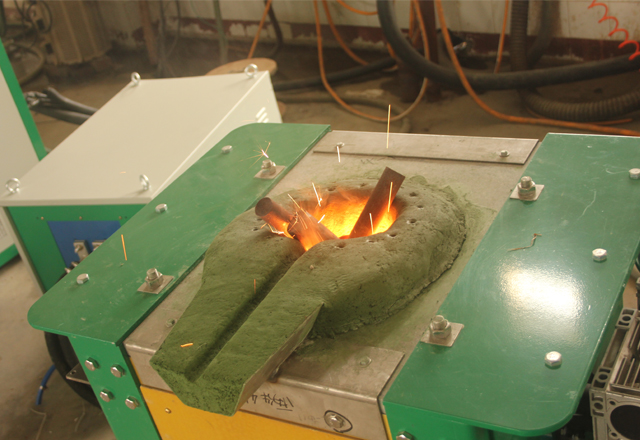

Induction Annealing And Normalizing

Induction annealingand induction tempering are very important processes in the heat treatment of the metal workpiece. These two processes can effectively change the hardness of the processed metal materials so as to meet different industry production requests. In the situations like steel wire annealing, spring wires annealing, tube annealing, shafts surface heating, gear teeth hardening, and sleeves inner bore heating, you can all find the existence of induction/wire annealing machines. Through annealing/tempering induction heat treatment, the performance of the workpiece can be much improved according to the customer's technical requirements to meet the process requirements of the workpiece. As a professional induction brass annealing machinemanufacturer in China, JKZ can provide you with both MOSFET and IGBT inverter types induction annealing machinewith a frequency range from 1KHz to 120KHz. We also sell single wire annealing machines with the power range of 7.5KW to 600KW in case you need to deal with the heating of workpieces of different shapes and different materials. For instance, with our wire induction brass annealer, you can easily process metals like carbon steel, stainless steel, copper, brass materials, titanium, metal parts like automotive parts, shafts, gears, sprockets, etc. Aiming to meet the requirements of various remote control PLCs and temperature control systems, JKZ's induction heating machines can perfectly meet our customers' heating requirements to the greatest extent.

As a professional induction heating company, JKZ has high-quality induction heating inverterfor sale. Welcome to contact us if needed.

Send product request

Other supplier products

| Steel Melting | The process of steel smelting to finishing are all completed in a high-temperature heating environment. The induction melting of iron, the composit... | |

| Steel Melting | The process of steel smelting to finishing are all completed in a high-temperature heating environment. The induction melting of iron, the composit... | |

| SWP-MT 15KHz-30KHz Medium Frequency Induction Heating Machine | SWP series are JKZ's newly designed and manufactured induction heating power supplies. The MT version of SWP series equipment uses IGBT as the c... | |

| Induction Hardening | The induction hardening process is a very important way in the manufacturing process of heat treatment of mechanical parts. In order to improve the... | |

| CX2020A 50-120KHZ 20KVA 45A High Frequency Induction Heating Machine | CX2020A high-frequency induction heating converter is designed to work at the frequency range of 50~120KHz and its output power range is 10KW. It i... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |