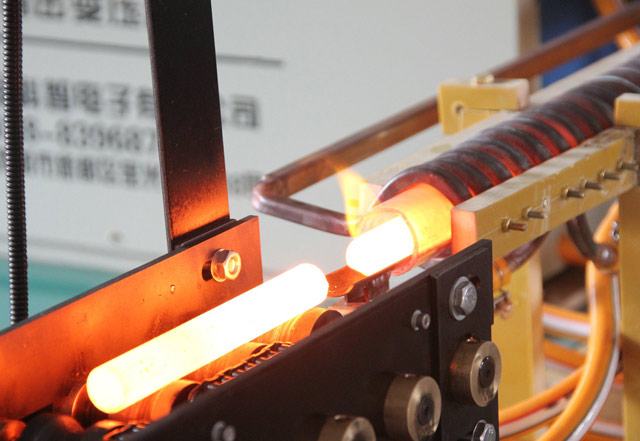

CX2020A 50-120KHZ 20KVA 45A High Frequency Induction Heating Machine

CX2020A high-frequency induction heating converter is designed to work at the frequency range of 50~120KHz and its output power range is 10KW. It is often used for induction brazing, welding, small parts forging heating and heat treatment. The core component of this high frequency induction welderis MOSFET, which is adapted from a well-known manufacturer. Its mature and stable circuits design ensure reliable equipment performance. With the remote control modules for start/stop, remote power adjustment can also be customized according to customer requirements, and this design makes it simple to embed this equipment into automated production lines.

Specifications of CX2020A High Frequency Induction Heating Machine

Our 20KW High-Frequency Induction Hardening Machine represents a cutting-edge heating method tailored for industrial applications. In numerous modern manufacturing processes, this heat-frequency machine provides an appealing blend of speed, uniformity, and precision control.

Operating on the principle of magnetic field induction, this high-frequency metal hardening furnace finds broad utility and is adaptable to a wide range of metal workpieces, regardless of their size or shape. The primary applications of the 20kw induction heaterencompass tasks such as melting, annealing, quenching, welding, heating, and various other heat treatment procedures. The following is the induction hardening machine specificationCX2020A:

|

Input voltage |

1 Phase 220V±10% 50/60HZ |

|

Input AC current |

45A |

|

Output power |

20KVA |

|

Output frequency |

50-120KHZ |

|

Duty cycle |

100% |

|

Power factor |

≥95% |

|

Cooling water pressure |

|

|

Cooling water flow |

≥0.7 m³/Hour |

Features of CX2020A High-Frequency Induction Quenching Machine

The CX2020A heat frequency machinehas a rapid and highly efficient heating process.

Precise heating targeting specific areas, resulting in minimal distortion.

Swift heating cycles with a clean, oxide-free workpiece surface.

The high-frequency induction welder has a user-friendly operation, promotes a favorable working environment, and minimizes environmental impact.

Easily adjustable heating temperature and duration control, ensuring consistent heating quality and enabling streamlined production processes.

Advantages of 20KW Induction Heater

Purpose of Heat Treatment: Induction hardening of heat-frequency machine is used to modify the characteristics of metal materials, enhancing mechanical properties like strength, hardness, plasticity, toughness, and fatigue strength. The process involves preliminary and final heat treatments. Preliminary treatments adjust material properties, such as normalizing low-carbon steel for increased hardness or spheroidizing high-carbon steel for reduced hardness. Final heat treatment achieves the desired mechanical properties by quenching and tempering.

Maintenance and Troubleshooting: Issues in the induction heating equipment may result from low insulation resistance or furnace short-circuits. To address this, a megohmmeter is employed to detect furnace resistance and eliminate short-circuits. If resistance is excessively low, rebuilding the furnace may be necessary.

Advantages of CX2020A high-frequency induction welder: This method offers deeper and harder layers with superior wear resistance compared to laser hardening. However, it can affect workpiece surface roughness, often necessitating additional machining to restore smoothness. The high frequency induction quenching machinecan produce a specialized laser melting and quenching coating, effectively reducing surface roughness in the fusion layer.

Application of CX2020A High Frequency Induction Heating Machine

Brazing of length 6~40mm carbide and other materials

Welding of Ø6~15mm copper pipe

Non-ferrous metal smelting

Forging heating of Ø8-10mm steel rod

Hardening of small workpiece whole piece or surface layer.

Send product request

Other supplier products

| MFS-120A 1-8KHZ 120KW 182A Medium Frequency Induction Heating Machine | MFS 120A induction heating power supply adopts IGBT as the core component. As a medium frequency induction heating machine, mfs machinehas an outpu... | |

| Induction Heating Machines | JKZ Induction Heating has been engaged in the manufacturing of induction heating machines for nearly 30 years. At present, there are currently more... | |

| Induction Heating Machines In Automotive Industry | The automobile manufacturing industry is the most typical and core application field of JKZ induction heating equipment. Situations like shafts sur... | |

| High Frequency Induction Heating Machine | The working frequency of CX series high frequency induction heating equipmentcovers 50KHZ ~ 120KHZ. You can find the existence of this high-frequen... | |

| CX2030C 50-120KHZ 30KVA 23A High Frequency Induction Heating Machine | CX2030C 50-120KHZ 30KVA 23A High Frequency Induction Heating Machine CX2030C 50-120KHZ high-frequency MOSFET type induction heater holds the outpu... |

Same products

| LY-TM1 Built-In Triple Burners Hybrid Hob | Seller: Zhongshan Katro Electrical Appliances Co.,Ltd | This household three-burner hybrid cookeris highly efficient, with each burner operating independ... | |

| FS2K1 Single Ceramic Cooker With Knob | Seller: Zhongshan Katro Electrical Appliances Co.,Ltd | This ultra-thin ceramic cooktopis thoughtfully designed with user experience in mind. It features... | |

| HT5062B3E Three Burners 45cm Electric Ceramic Stove | Seller: Zhongshan Katro Electrical Appliances Co.,Ltd | This built-in household ceramic cooktopfeatures a distinctive circular sliding control that adds ... | |

| ID35-T07 Dual Zone Portable Induction Cooktop | Seller: Zhongshan Katro Electrical Appliances Co.,Ltd | ID35-T07 Dual Zone Portable Induction Cooktop Product Description The kitchen hob offers temper... | |

| IF7250B3-AC Built-In Four Burners Slider Induction Stove | Seller: Zhongshan Katro Electrical Appliances Co.,Ltd | With a powerful total output of 7200W, this induction cookeris designed to meet customers high co... |