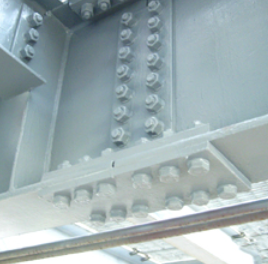

STEEL STRUCTURE PAINT

The anti-corrosion coating solution for steel structure buildings is mainly made according to ISO12944, including serving life, corrosion environment, structural design, surface treatment, coating system, coating product performance, construction supervision and the solution plan of maintenance support.

When designing a anti corrosion coating for structural steel, the first thing is to determine the corrosion environment of the steel structure, then determine the required service life of the anti-corrosive paints, and finally determine the supporting plan of the anti-corrosive paints, including the product type and the thickness of the paint film.

According to the definition of corrosive environment in ISO12944-2, remote areas, low-pollution areas, and environment inside buildings with heating are C1 and C2 environments. In urban and industrial environments, the moderately polluted area is the C3 environment. Industrial areas, coastal areas, chemical plants and other places with high pollution or salt spray can be regarded as C4 environments. High-humidity industrial areas and places with particularly severe pollution can be identified as C5-I industrial corrosion environments. High humidity and high salinity are C5-M marine corrosion environments.

Features of Steel Structure Paint

Anti-rust primer

In the anti-corrosion coating system of steel structure, the role of anti-rust primer is very important. Commonly used anti-rust primers include epoxy zinc-rich primer, inorganic zinc-rich primer and thick build modified epoxy paint.

The function of the intermediate paint is to increase the thickness of the coating to improve the shielding performance of the entire coating system. The most commonly used intermediate paint is epoxy mica iron oxide intermediate paint.

The main function of the topcoat is to shield the sun's ultraviolet rays and the destructive effect of the air pollution on the coating, resist wind, snow and rain, and have a good decorative property. Highly weather-resistant anti-corrosion topcoats on the surface of steel structures are mainly acrylic polyurethane topcoats, fluorocarbon topcoats and polysiloxane coatings.

ISO12944-2

According to the definition of corrosive environment in ISO12944-2, remote areas, low-pollution areas, and environment inside buildings with heating are C1 and C2 environments. In urban and industrial environments, the moderately polluted area is the C3 environment. Industrial areas, coastal areas, chemical plants and other places with high pollution or salt spray can be regarded as C4 environments. High-humidity industrial areas and places with particularly severe pollution can be identified as C5-I industrial corrosion environments. High humidity and high salinity are C5-M marine corrosion environments.

ISO12944-1 divides the design service life of anticorrosive coating system into three durability ranges.

1) Low durability, design life is less than 5 years.

2) Medium durability, design life is 5-15 years.

3) High durability, design life is more than 15 years.

The steel structure building requires a high service life, so for the steel structure coating system, a high durability service life is also required. Therefore, the structural paint design for steel structure buildings is more than 15 years, or even more than 25 years.

We are apaints manufacturer. we provide industrial protective paints, fireproof paint for steel beams, anti corrosion primer for steel, c5 corrosion environment, solvent free paintand etc. For more information about types of anti corrosive paintsand how to measure painting area of structural steel, please feel free to contact us!

Send product request

Other supplier products

| Asphalt Aluminum Ship Bottom Antirust Paint | Asphalt aluminum ship bottom antirust paint is made of asphalt, aluminum powder, extender pigment, solvent. It has good water resistance, rust and ... | |

| STEEL STRUCTURE PAINT | Steel Structure Coating The anti corrosive paint for steelstructure buildings is mainly made according to ISO12944, including serving life, corr... | |

| General-Purpose Chlorinated Rubber Anticorrosive Coating (Self-Priming Paint for Ships) | The general-purpose chlorinated rubber anticorrosive paint is a one-component general-purpose marine anticorrosive paint. It can be used as a prime... | |

| High Chlorinated Polyethylene Anticorrosive Intermediate Paint | High chlorinated polyethyleneanticorrosive Intermediate Paint is composed of high chlorinated polyethylene resin, anticorrosive pigments, additives... | |

| Epoxy Primer Sealer for Concrete Parts | Epoxy primer-sealer for concrete parts is a two-component self-drying paint composed of epoxy resin, additives and solvents, and a special epoxy cu... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |