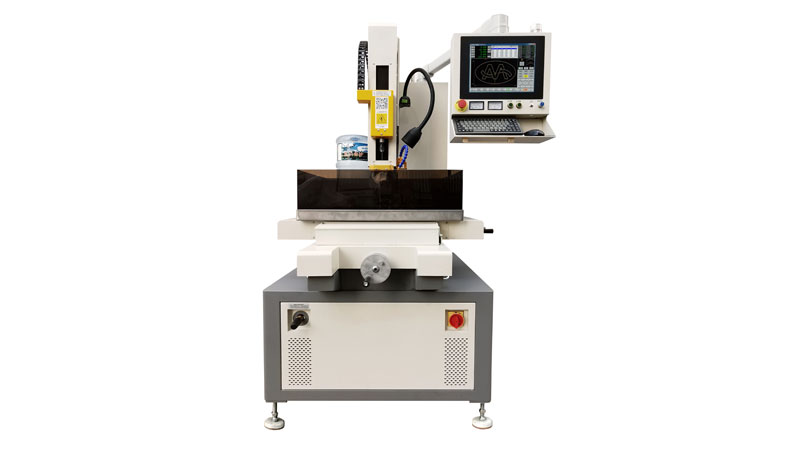

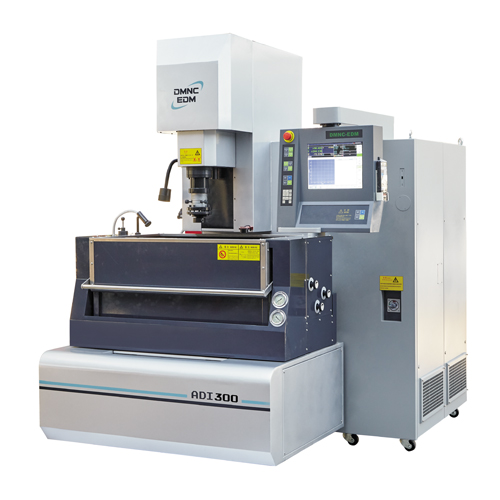

KD-DC430A(B,C) CNC EDM Drillig Machine X×Y=400×300mm

All supplier products

KD-DC430A(B, C) CNC EDM Drillig Machine Features

- The system adopts a touch screen industrial control computer and Win7 operating system. It runs fast and can process massive data at the same time.

- With a rich data interface, the system can directly import data and edit it through the U disk, network port, and wireless to produce the most reasonable processing route.

- Support X.Y.Z three-axis CNC machining, suitable for plane and arc hole drilling. (Optional) It can be installed to realize W.C five-axis CNC processing, suitable for uneven workpieces with steps, and a rotary table for processing round workpieces and inclined holes.

- Comes with an expert process library, just enter the workpiece material, electrode diameter, processing requirements and other conditions, the processing parameters are automatically retrieved, and the hole processing parameters can also be manually adjusted.

- Equipped with automatic centering, automatic edge search, and automatic workpiece surface search.

- Precise depth control, automatic detection of electrode loss, and electrode loss can also be set manually.

- Automatic detection of penetration, depth coordinate can also be set manually.

- The XY axis has a closed-loop function, which can achieve high-precision positioning.

- Hand-in-one integrated processing method, the X and Y axes are automatically locked after positioning and can be unlocked manually.

- ☆ In order to ensure the quality of the aperture, the electrode tubes with specifications below 0.3mm are selected for manual processing.

KD-DC430A(B, C) CNC EDM Drillig Machineworking conditions:

- Power supply: 380V±10%, 50HZ±10%

- Ambient temperature: 2℃-40℃. The recommended room temperature is 20℃±1℃

- Relative humidity: ≦75% (no strong alkali, no strong electromagnetic field, no moisture)

- ≤80db

KD-DC430A(B, C) CNC EDM Drillig Machine Technical parameters

|

Item |

Technical terms |

DC430C |

DC430B |

DC430A |

|

1 |

Electrode diameter (mm) |

Φ0.3-Φ3.0 |

Φ0.2-Φ3.0 |

Φ0.1-Φ3.0 |

|

2 |

Machine head travel (mm) |

280 |

280 |

280 |

|

3 |

Spindle servo travel (mm) |

380 |

380 |

380 |

|

4 |

1500 |

1500 |

1500 |

|

|

5 |

Rotation speed of the spindle (rpm) |

0-200 adjustable |

0-200 adjustable |

0-200 adjustable |

|

6 |

Worktable size (mm) |

440×320 |

440×320 |

440×320 |

|

7 |

X×Y travel(mm) |

400×300 |

400×300 |

400×300 |

|

8 |

Power supply |

3 phase 380V/50Hz |

3 phase 380V/50Hz |

3 phase 380V/50Hz |

|

9 |

Digital display type |

X, Y, Z |

X, Y, Z |

X, Y, Z |

|

10 |

8 |

12 |

12/8 |

|

|

11 |

Working liquid supply device |

Electrical plunger pump |

Pneumatic pump |

Double pumps (electrical pump + pneumatic pump) |

|

12 |

300 |

300 |

300 |

|

|

13 |

Overall dimension of machine(W×L×H) |

1000×1000×2200 |

1000×1000×2200 |

1000×1000×2200 |

|

14 |

Machine weight(kg) |

680 |

680 |

680 |

|

15 |

X, Y, Z configuration |

X, Y, Z precise ball screw |

X, Y, Z precise ball screw |

X, Y, Z precise ball screw |

|

X, Y, Z axis linear guideway |

X, Y, Z axis linear guideway |

X, Y, Z axis linear guideway |

||

|

W axis motorized X, Y, Z axis NC control |

W axis motorized X, Y, Z axis NC control |

W axis motorized X, Y, Z axis NC control |

||

|

16 |

Positioning accuracy |

|||

|

17 |

Feed ratio of X, Y axis |

1000mm/min |

1000mm/min |

1000mm/min |

Specification of control system

|

1 |

Control axis |

X, Y, Z three axes |

|

2 |

Drilling axis |

Z axis |

|

3 |

Max machining current |

30A |

|

4 |

Max machining speed |

30-60mm/min |

|

5 |

Max input power |

|

|

6 |

≤0.8% |

|

|

7 |

Working liquid supply |

Electrical plunger pump |

|

8 |

Digital display axes |

X, Y, Z three axes |

Recycling tank(optional)

|

1 |

Capacity |

110L |

|

2 |

Weight |

45kg |

|

3 |

Outer dimension |

920×460×750mm |

|

4 |

Material |

Stainless steel |

|

5 |

Filtering |

Changeable filter |

For more information about what is an edm machineand buy spark edm machine, please feel free to contact us!

Send product request

Other supplier products

| DK7750 CNC EDM Wire Cutting Machine With X×Y=500×630mm | Features of High-speed HF Power Φ0.18mm, the diameter will be Φ17mm after the job of cutting 500,000mm2. BIEM i... | |

| General Purpose CNC EDM Wire Cut Machine F Structure | DK77 series cnc wire cutting machinehas non-resistors HF power with Max cutting speed higher than 300mm2/min, Max cutting thickness is higher than ... | |

| ZNC Die Sinking EDM Machine | ZNC electrical discharge machining machine is the traditional type with X and Y axis manual control, usually operator needs to manually move the w... | |

| EDM Wire Cut Parts | EDM Wire Cut Parts Diamond Brand Molybdenum Wire of CNC Wire Cut EDM ZGCC Molybdenum Wire For CNC Wire Cut EDM Machine Power Feed Contact ... | |

| CNC Die Sinker EDM Machine | CNC Die SinkerEDM Machine For Sale As a professional CNC Die Sinker EDMMachine manufacturer, we aim at providing you erosion machines with high qu... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |