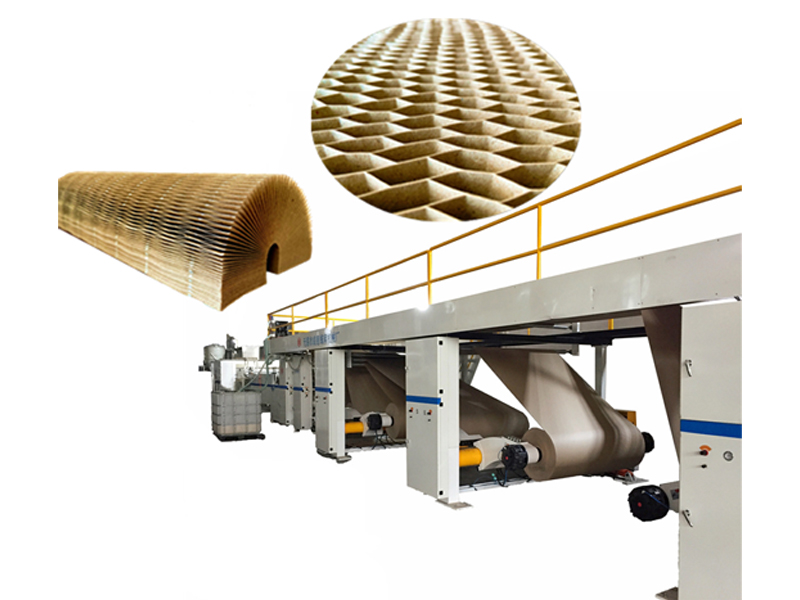

Honeycomb Paper Core Machine

The Paper honeycomb core machineincludes 2 models. There are 7 parts: Heavy load hydraulic paper stand, Paper core gluing machine, Paper core conveying pressing machine, dryer, High-speed cutting machine, Paper core conveying machine, and Electrical control cabinet. This paper honeycomb core machine can produce honeycomb paper cores in a one-stop manner. The production process starts from the base paper to directly produce the cut honeycomb paper core. The introduction of foreign advanced technology of paper honeycomb core machines eliminates the need for paper cutters and butting machines for the traditional production of honeycomb cardboard. The biggest advantage of the paper honeycomb core machine is high automation and low labor cost.

Types of Paper Honeycomb Core Machine

High Speed Paper Honeycomb Core Machine

Model: CX-2000 Type: Continuous type Length of the total line: 33m Power supply: 66kw Cutting speed: 0-720cuts/min

Normal Speed Honeycomb Paper Core Machine

Model: CX-1600 Type: Continuous type Length of the total line: 32m Power supply: 60KW Height of honeycomb paper: 6-100mm Cutting speed: 380cuts/min

Advantages of Honeycomb Paper Core Machine

The cutting precision of paper honeycomb core machine is high, and the speed is fast. From the raw paper in to the cardboard out, honeycomb paper core machine is completed at one time on a fully automatic production line. Only 2 to 3 operators are required, the utilization rate of base paper is high, and the technology of honeycomb paper core machine is advanced. Our paper honeycomb core manufacturers has high degree of automation, advanced technology, low loss, and touch screen operation. The operation of paper honeycomb core machine is simple and convenient for workers, and the performance is stable and reliable. It is at the leading level in the domestic industry.

Features of San MachineryHoneycomb Paper Core Machine

Honeycomb paper core machine can produce two kinds of honeycomb paper with different cells. Two sets of honeycomb gluing mechanisms with different cell sizes (the cell size is determined by the user) 4.5mm and 6mm paper glued simultaneously. Tooth rollers, gluing rollers, fine grinding, hard chrome plated surface, with umbrella size, seal ring for main gluing rollers. Each tooth roller can be transverse adjusted to adjust the cell shape of honeycomb. The decorative board on the paper honeycomb core machine is raised, the sides are curved, the paper platform guardrail is raised. Paper core is conveyed stably (Conveyor belt adopts NBR), which can adjust the frequency and speed individually on the paper honeycomb core machine. The honeycomb paper core machine is controlled by PLC, and it can walk synchronously. Besides the running speed can be adjusted independently for each section. Electric cabinet is dustproof.

Applications of Honeycomb Paper Core Machine

Paper honeycomb core machineis widely used in packaging industry, transportation industry, making crafts or making honeycomb cardboard, etc. Honeycomb paper core has the characteristics of light material and environmental protection.

As one of paper honeycomb core suppliersand paper honeycomb core manufacturers, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Paper Slip Sheet Machine | The paper slip sheet machineis used to make paper slip sheet. This is the latest developed paper sheet production line. SANPPL-1600F line is to pro... | |

| Honeycomb Cutter | This category honeycomb cutterincludes all kinds of machines that cut honeycomb products into different shapes, including honeycomb paper core expa... | |

| Paper Slitting Rewinding Machine | Paper slitting and rewinding machineis used to slit the big paper rolls into small paper rolls , then rewind them. The hydraulic shaftless paper ho... | |

| Paper Edge Protector Die Notching Machine | Paper Edge Protector Die Notching Machine Paper protector flexo die paper slitting machineis to make V cut for outer round protector and line cut ... | |

| Honeycomb Paper Core Expander | This paper core expander is applied to expand and dry the honeycomb paper core. By heating and drying, evaporating the water in it, and then stretc... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |