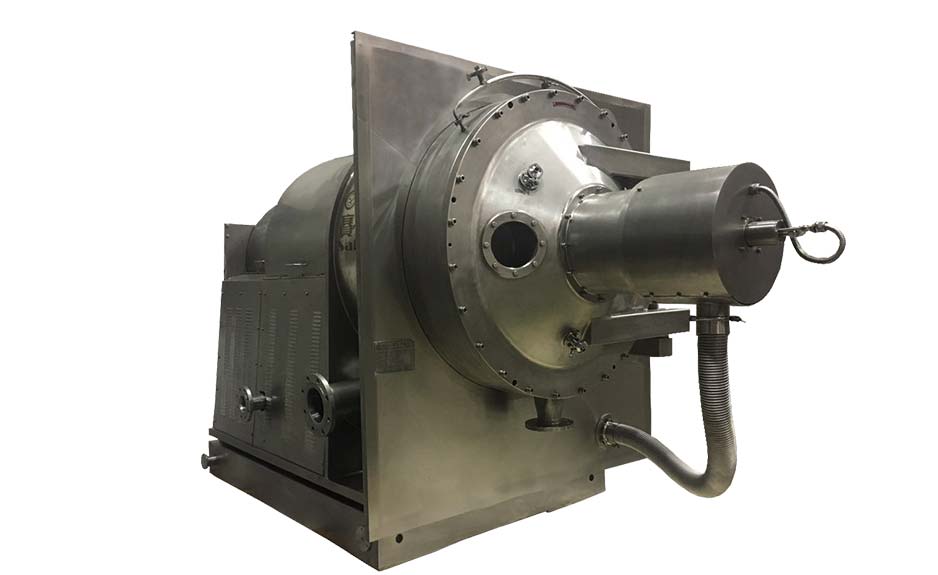

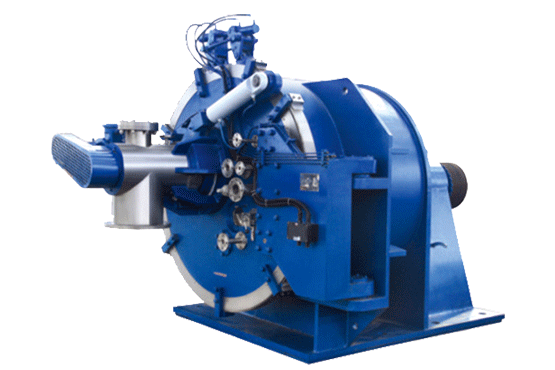

HR PISTONS PUSHING CENTRIFUGE

HR PISTONS PUSHING CENTRIFUGE

As a good and professional pusher centrifuge manufacturer, Saidelihas been making high quality pusher centrifuge parts. When the drum runs at a full speed driven by the main motor and transmission belt, the suspension of HR pistons pusher type centrifugewill be led to the product distributing plate through the feeding pipeline continuously. Then the suspension will be distributed evenly on the filter net in the inner first-grade drum. Most of the liquid phase will be thrown out through the filter net and the filter holes on the drum wall, and then drained outside through the liquid outlet. The solid will be intercepted on the first-grade drum and form a cake ring.

HR PISTONS PUSHING CENTRIFUGE SPECIFICATION

HR Model and Main Parameters

|

Item/Model |

HR400-N |

HR500-N |

HR630-N |

HR800-N |

HR1000-N |

|

Drum diameter (mm) inner/outer basket |

337/400 |

410/500 |

560/630 |

720/800 |

920/1000 |

|

Length of filtering (mm) |

160/160 |

180/180 |

240/240 |

300/300 |

240/320 |

|

inner/outer basket |

|||||

|

Speed (r/min) |

1500-2200 |

1200-2000 |

1000/1800 |

800-1600 |

650-1250 |

|

inner/outer basket |

|||||

|

Separating factor (N) |

503-1083 |

402-1118 |

352-1140 |

286-1145 |

236-875 |

|

inner/outer basket |

|||||

|

Length stroke (mm) |

40 |

50 |

50 |

50 |

50 |

|

Frequency of stroke (mm) |

30-80 |

50-70 |

30-80 |

30-80 |

20-70 |

|

Main motor power (KW) |

11 |

30-45 |

37-55 |

55-75 |

75-90 |

|

Oil pump motor Power(KW) |

22 |

30 |

45 |

45 |

|

|

Production capacity (t/h) |

1-8 |

5-15 |

8-25 |

15-40 |

18-50 |

|

Overall dimensions L×W×H (mm) |

2460×1286 |

3590×1430 |

3500×1760 |

3700×1800 |

4200×1900 |

|

×1030 |

×1642 |

×1265 |

×1450 |

×1900 |

|

|

Weight (Kg) |

2480 |

3500 |

4000 |

6000 |

12000 |

PUSHER CENTRIFUGE WORKING PRINCIPLE

HR series centrifuge is a kind of horizontal two-stage pistons pushing centrifuge and filtering centrifuge with continuous operation. Materials are fed continuously through feeding pipe and distributed evenly on the inner drum wall under the full involving speed of both inner and outer drum. Under the centrifugal force, liquid will be drained outside through the filtering net and the filtering holes on the drum wall while the solid will be intercepted in the inner drum and form a cake ring. While the drums of the two grades are revolving together at a same speed, the inner drum will move reciprocately continuously in axial direction under the driven of the pistons,then the pushing plate will be able to push out the filter cake from the inner drum. In the next step, the filter cake will be pushed into the outer drum for further separation. Then the outer edge of the inner drum will push the new filter cake to the out of the outer drum continuously and then discharged through the scraping groove.

PUSHER CENTRIFUGE MACHINEFEATURES

All operations under full speed: Automatic pusher centrifuge operationwith continuous discharging and great capacity. Crystal shape will be kept completely;Filter cake can be washed inside the machine; Product contact parts adopt stainless steel with good anti-corrosion property.

PUSHER CENTRIFUGE MACHINE APPLICATION

Two stage pistons pushing centrifuge usually used for separating even suspension with medium and coarse particles(>0.1mm) and high concentration(>30%). The bigger the particle, the higher the solid content, the higher the capacity and the better the separating effect.

Our company started to manufacture HR pistons pushing centrifuge since year 1965 with all models and more than 7000 sets output which has been widely used in chemical, fertilizer, salt, pharmacy and environment protection area.

As a reliable industrial centrifuge machine manufacturer, we can offer sorts of related products for sale, if you have needs, please contact us.

Send product request

Other supplier products

| FSD CENTRIFUGAL DRYER | This industrial centrifugal dryerintegrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly su... | |

| HR PISTONS PUSHING CENTRIFUGE | HR PISTONS PUSHING CENTRIFUGE As a good and professional pusher centrifuge manufacturer, Saidelihas been making high quality pusher centrifuge par... | |

| GKH AUTOMATIC SIPHON HORIZONTAL SCRAPER CENTRIFUGE | This screen centrifuge is controlled by PLC and regulates the speed by frequency convertor. The braking system of continuous centrifuge applies dyn... | |

| LBF Platform Hermetical Full Housing Open Top Discharge Centrifuge | LBF PLATFORM HERMETICAL FULL HOUSING OPEN TOP DISCHARGE CENTRIFUGE Now LBF centrifuge platformhermetical full housing open-top discharge centrifug... | |

| Products | SAIDELI-PROFESSIONAL CENTRIFUGE MACHINE MANUFACTURER Jiangsu Saidelicontinuously develops high-tech and top-quality products which include Industr... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |