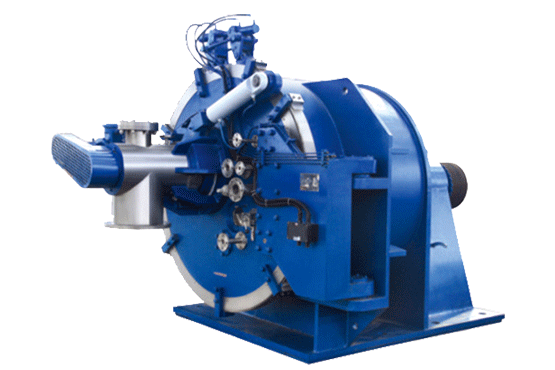

LGZ AUTOMATIC SCRAPER BOTTOM DISCHARGE CENTRIFUGE

LGZ AUTOMATIC SCRAPER BOTTOM DISCHARGE CENTRIFUGE

In accordance with users' demand, L(P)GZ bottom discharge centrifuges' procedures such as feeding, separating, washing, dehydrating, and discharging can all be automatically finished followed by remote control.

Highlights of LGZ Automatic Scraper Bottom Discharge Centrifuge

The bottom discharge centrifugeadopts whole enclosed structure with dependable seal facility which is filled with nitrogen to meet the explosion proof demand.

Adopted with quick open clamshell structure and optional swash plate distributor, products can be distributed evenly to reduce vibration caused by unbalanced distribution. With additional washing function, it has a better cleaning effect.

The motor is set on the top of the bottom discharge centrifuge machineand directly linked to main shaft which will bring higher transmission efficiency and reduce friction powders.

Pneumatic assisted scraper is adopted to remove the remnant filter cake and CIP system is optional to secure clarity to be in accordance with GMP Norm.

Frequency control system is adopted to ensure a stable start-up. PLC is adopted to ensure a complete automatic process including feeding, filtering, washing and discharging, etc. It adopts dynamic(regenerative) braking without friction powder pollution and friction heat, so it's much safer.

No need of human supervision. Following security systems of bottom discharge centrifuge are adopted: self-monitoring and protecting system, speed inspection, product level detection, over-vibration protection, over-heat protection for motor, mechanical and electric double interlock for scraper rotary and movement, interlock for lid's open and machine's running.

If you want to know more about bottom discharge centrifuge workingprinciple, please visit our website.

As a reliable industrial centrifuge factory, we can offer sorts of industrial centrifuge machinefor sale, if you are interested, please contact us.

Send product request

Other supplier products

| LBF Platform Hermetical Full Housing Open Top Discharge Centrifuge | LBF PLATFORM HERMETICAL FULL HOUSING OPEN TOP DISCHARGE CENTRIFUGE Now LBF centrifuge platformhermetical full housing open-top discharge centrifug... | |

| HORIZONTAL CENTRIFUGE MACHINE | The horizontal centrifuge machine manufactured by Saideli is with high production capacity and separation performance is excellent. The horizontal ... | |

| SAIDELI-INDUSTRIAL CENTRIFUGE SEPARATOR MACHINE MANUFACTURER | Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops high-tech and top-quality products which include industrial c... | |

| LLGZ PULL BAG SCRAPER BOTTOM DISCHARGE CENTRIFUGE | LLGZ PULL BAG SCRAPER BOTTOM DISCHARGE CENTRIFUGE L(P)LGZ vertical basket centrifuges are suitable for solid-liquid separation of fibroid products... | |

| GKH AUTOMATIC SIPHON HORIZONTAL SCRAPER CENTRIFUGE | This screen centrifuge is controlled by PLC and regulates the speed by frequency convertor. The braking system of continuous centrifuge applies dyn... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |