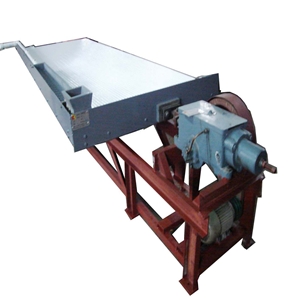

Shaker

Application fields:Mineral processing

Materials:It is widely used in the tin,wolfram,gold,and silver, lead, zinc, tungsten, tantalum, niobium,titanium, manganese, iron and coal.

Product advantage:

Shaker is a combination of the internal shaking and mineral processing technology of gravity, high enrichment ratio, sorting efficiency good, the advantages of simple operation, and again at the final concentrate and final tailings. Compared with traditional technology with advantages of no pharmacy, low energy consumption, easy to manage, with high performance-price ratio.

Woking principle:

6-S shaker belonging to the gravity concentrator, chute evolved by plane, later characterized by asymmetric oscillating movement and self-contained. 6-S rocking bed by bed, frame and drive mechanism consists of three parts, hand deliver the bed trapezoidal or diamond, horizontal 1 ° ~5 ° tilt, oblique upper edge configuration to the trough and to the sink, bed surface along the longitudinal layout of beds, and its height from the drive side to the lower side.The entire bed frame supports,at the bed end installing driving device,which can make the bed before approaching the end with quick-return movement characteristics,known as differential movement.6-S Shaker is the separation of fine ores used in mineral processing equipment and effective inspection when handling metal ore particle size range is 3~O. 019 mm ceiling when the coal particle size up to 10 mm. 6-S Shaker is the outstanding advantages of high precision separation, sorting may be high grade concentrates or waste tailings, and also received more than one product.Planar 6-S Shaker care easier, convenient adjustment.Main drawback is that the device covers an area of large, plant area of low processing capacity. Table work is on a tilt bed with mechanical stone a symmetric combined effect of reciprocating inclined flow and thin-layer, the particles loose layering on the bed, so that mineral separation process by different densities.Specification: Name Unit Shaker of coarse sand Shaker of fine sand Slime table mesa size

Mesa dimension length mm 4450 4450 4450

Transfer side width mm 1855 1855 1855

Ore concentrate side width mm 1546 1546 1546

Maximum feeding mm 2 0.5 0.15

Capacity T/d 30-60 10-20 15-25

Concentration % 25-30 20-25 15-25

Stroke mm 16-22 11-16 8-16

Frequency f 15-48 48-53 50-57

Yield of water cleaning T/d 80-150 30-60 10-17

Transverse slope ° 2.5-4.5 1.5-3.5 1-2

Longitudinal slope % 1.4 0.92 ——

Cross fall tailing out the surface angle ° 32-42 40 42

Ore dressing area —— 7.6 7.6 7.6

Linear scale ratio of countertop length —— 2.6 2.6 2.6

Motor power kw 1.1 1.1 1.1

Other supplier products

|

|

Intermittent Ball Mill Series |

Technical Advantage:

Intermittent Ball Mill is mainly used for materials, grinding, the fineness of the product is uniform, save power. The machi... |

|

|

Vibrating Screen Series |

Application: It is suitable for quarry screening ballast, also can classify coal, mining, mineral processing, building materials, electricity and... |

|

|

Shaker |

Application fields:Mineral processing

Materials:It is widely used in the tin,wolfram,gold,and silver, lead, zinc, tungsten, tantalum, niobium,ti... |

|

|

Belt Conveyor Series |

Application: Metal and non-metallic mining, etc

Material: It is suitable for crushing compressive strength which is not higher than 320 Mpa (Mpa)... |

|

|

Disc Polluter |

Application fields:it can be widely used in gold mining, chemical plant, construction and foundry for uniformly continuous, quantitative material... |

All supplier products

Same products