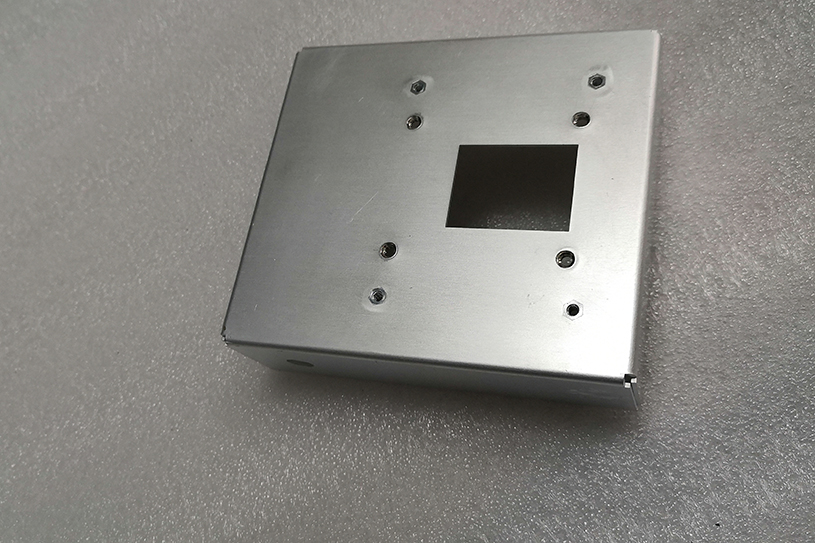

Sheet Metal Chassis

The sheet metal chassis is a chassis that is required for the use of a comprehensive cold working process for metal sheets (usually below 6 mm). Processing techniques include shearing, punching, cutting, compounding, folding, welding, riveting, splicing, forming (such as car body). Its remarkable feature is the same thickness of the same part. The chassis made of sheet metal can meet the various functions and appearance requirements of the chassis, such as metal chassis for robot and aluminum robot chassis. The metal chassis can make the stamping die manufacturing at a low cost.

Process Technologies in Sheet Metal Chassis Fabrication

The sheet metal processing chassis is an important part of the sheet metal processing industry. The manufacturing process of sheet metal chassis requires a lot of technology. To get sheet metal chassis, we need some specific technologies. Main technologies in metal chassis fabrication are as following:

(1) Welding: Welding processes mainly include arc welding, electroslag welding, gas welding, plasma arc welding, fusion welding, pressure welding, brazing and so on.

(2) Stretching: The radius of curvature between the bottom of the pull tab and the straight wall should be b, that is, r1≥t, generally r1=(3~5)t, and the maximum radius of curvature should be less than or equal to the thickness of the plate 8 times of, that is, r1≤8t.

(3) Blanking: According to different processing methods, blanking can be divided into ordinary blanking, counting punching, shear cutting, laser cutting, wind cutting, etc.

Sheet Metal Chassis Materials

Different uses of CNC chassis determine the design and the selection of material. For vehicles, the material used for the construction of the chassis is usually carbon steel, but it is also becoming more commonplace that they are made up of aluminum alloys considering its light-weight characteristic.

Materials for chassis CNC: SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel.

Why Choose HSJ for Customized Sheet Metal Chassis?

Except our talented workforce and advanced machine, the design engineers working for HSJ Metal Fabrication are equipped with skills to optimize the weight and size of the chassis.

Why Choose HSJ for Customized Sheet Metal Chassis?

By years of experience and standard software, HSJ Metal Fabrication performs can simulation on the design to produce the prototype. After designing and manufacturing the product, we will do lots of testing tasks of the product to ensure the quality of your desired products.

How HSJ Ensure the Quality of Chassis Fabrication?

Raw material testing:Inspection of the raw materials used in production we have professional incoming material inspector to inspect them.

In-production control: we have rich experience operator to check the whole process make sure each step of production is within control limits.

Sheet Metal Chassis Application

Electronic part

Customized sheet metal fabrication metal chassis

Surface treatment (finish)High polish, brush, sandblast, anodization plating (nickel, chrome), powder coat , Lacquer painting, silkscreen, pad printing

Electronic part

Thickness:0.1mm—20mm

Tolerance: + / - 0.02 mm - 0.1 mm

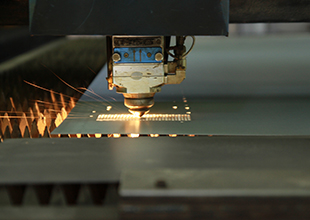

Equipment: HSG(HS-G3015A) laser machine,bending machine

Production capacity: pcs

There are many sheet metal components manufacturers, but we are one of the best choices for you.

As one of the most professional china sheet metal forming manufacturers, HSJ Metal Processing has the following capabilities meet your needs for CNC steel parts.

Other supplier products

|

|

Metal Fabrication |

Shenzhen HSJ Metal Fabrication Co., Ltd. has rich experience in providing high-quality sheet metal fabrication products based on customers requirem... |

|

|

Stamping Computer Enclosures |

Stamping Computer Enclosures

Surface treatment:

in the photo we not show the surface treatment but we could offer the powder coating and anodizin... |

|

|

SECC Stamping & Forming Shell |

Material:

SECC (Electrolytic plate) 2.0mm

Surface treatment:

powder plating + silk-screen printing (we also offer logo or words printing)

O... |

|

|

Custom Bending Electronic Enclosure |

Custom Bending Electronic Enclosure

Material:

SPCC, SECCSGCCStainless Steel,copper, aluminum,and so on

Surface treatment:

Power coating, ... |

|

|

Machined Enclosures |

Machined Enclosures

Material:

Carbon Steel/Stainless Steel/aluminum

Surface treatment:

Paint, powder coat, polish, silk-screen printing, ... |

All supplier products

Same products