C1 Latent Traction AGV Guided Vehicle

The latent traction series automated guided vehicle for sale can lurch under the feeder, use the towing bar to automatically lift, hook or drop off the feeder. This series of AMR/AGV guided vehicles are divided into one-way, two-way and omnidirectional according to the direction of AMR/AGV operation, and the navigation method is magnetic stripe navigation. Towing capacity is 500kg~2500kg. The latent traction series AMR/AGV guided vehicle has a wide range of applications, compact structure, flexible operation and a high degree of automation. These agv vehiclesare widely used in many industries such as flat panel display, new energy lithium battery, automobile and spare parts, food and beverage, 3C electronics, home appliances and so on.

CASUN C1 Latent Traction AMR/AGV Vehicle Types

AGV casunprovides various agv vehicle types, which follow a configurable wizard path to improve stocking, picking, and transporting capabilities in different kinds of conditions where space is valuable. Casun's unparalleled portfolio of AMR/AGV guided vehicles improves productivity, limits product damage, reduces labor costs, and supports increasing automated operations.

C1-11B Unidirectional Latent Towing AGV

Navigation

Magnetic tape

Vehicle Dimensions

Load Capacity

1200KG

Rated Speed

0~45m/min

Turning Radius

650mm

Guidance Accuracy

±10mm

Stopping Accuracy

±10mm

Driving Mode

Differential drive

Latent traction series uses magnetic tape navigation, which is a much mature navigation method with the advantages of simple construction, stable running and easy operation, thus assuring the rapid deployment of an on-site environment.

Equipped with CASUN's independently developed Central Control System, this series can not only allow customers to monitor AGV operating status at any time but also can realize intelligent traffic control to ensure efficient and smooth cargo delivery.

Latent traction AGV's running and stopping accuracy can achieve ±10mm.

The Latent Traction AGV has strong industry adaptability, can be widely applied in multiple industries, including lithium battery, automotive, 3C electronics, semiconductors, home appliances industry, and so on.

Applications Of AMR/AGV Guided Vehicle

Adapt to Transfer Rack With Caster

The Latent Traction AMR/AGV can match various types of rack with the caster. With the combination of rack and AMR/AGV, a flexible production line is formed, thus fast transport of material in the factory could be achieved.

Flexible Production Line Solution on Lithium Battery PACK

Latent Traction AMR/AGV and racks on the Pack production line form the flexible production line, they can work independently or together. In a traditional production line, if any malfunction occurs, the line has to be stopped, but with our flexible solution, failed AMR/AGV will be replaced immediately thus ensuring productivity.

Applied in Automotive Industry

When applied in the automotive industry, the Latent Traction AMR/AGV guided vehicle can transport the SPS rack independently or it can form a flexible production line with an SPS rack to replace the traditional transport line which has high cost and require large space. The Latent Traction AMR/AGV vehicles could be applied in every production link of the standardized automotive production process.

How to choose the right AGV Guided Vehicle?

We will need to consider some factors when we are ready to buy AMR/AGV vehicles. In fact, we can make a list of all things to consider in order to be prepared when talking about business with potential AMR/AGV vehicle manufacturers.

If you want to know more about agv price, please contact us.

Send product request

Other supplier products

| C5-P1 Balanced Forklift AGV | C5-Q1 is balanced and heavy laser navigation forklift AGV, small model, small space during transportation, no external legs, no need to worry about... | |

| CCM Unit Load Carrier AGV Trolley | Load shifting series AGV trolley can autonomously navigate to the docking terminal according to the scheduling task, realizing the fully automated ... | |

| C5-Q2 Reach Forklift AGV | C5-Q2 is a forward-moving laser navigation forklift slam agv.The gable fork can be telescopic to avoid the interference between the machine and the... | |

| C3-15 Single Conveyor Deck Load AGV | C3-15 single conveyor deck load forkAGVuses the load shifting roller platform to automatically dock with the conveyor line or machine for material ... | |

| C5-B2 Pallet Mover AGV | C5-B2 is a laser guided forklift AGV independently developed by Casun, with a load capacity up to 800KG, small volume and small turning radius. Thi... |

Same products

| SK222 Non Sparking Phillips Screwdriver | Seller: Hebei Sikai Safety Tools Manufacturing Co.,Ltd | SK222 Non Sparking Phillips Screwdriver Our non-sparking Phillips screwdriveris made from beryll... | |

| K238B Non-sparking Sledge Hammer | Seller: Hebei Sikai Safety Tools Manufacturing Co.,Ltd | K238B Non-sparking Sledge Hammer Non sparking sledge hammer is one kind of heavy-duty non sparki... | |

| PV Cleaning Vehicle | Seller: Trinabot Co., Ltd | The PV cleaning vehicleutilizes a cutting-edge leapfrog design structure, incorporating four-whee... | |

| YCX M9 Professional Screen Tester for True Tone and Refresh Rate Testing | Seller: Phonefix | YCX M9 Intelligent Screen Tester works with iPhone 6-16 Pro Max, Samsung, Huawei, Xiaomi, OPPO, V... | |

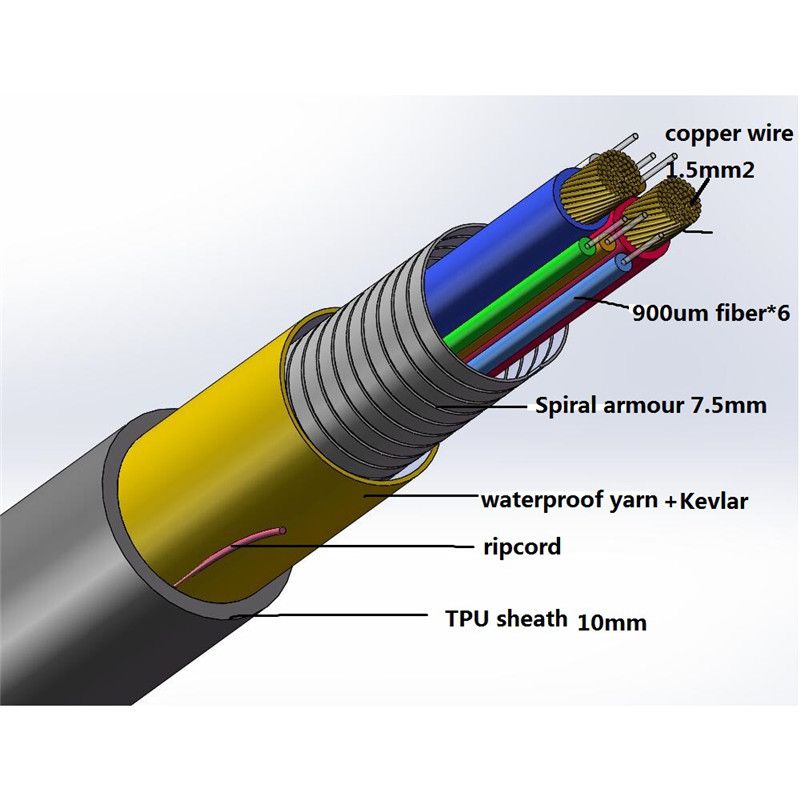

| copper fiber composite cable | Seller: Shenzhen Wirenet Telecom Technology Co., Ltd. | copper fiber composite cable Copper Fiber Composite Cable are hybrid cables that combine op... |