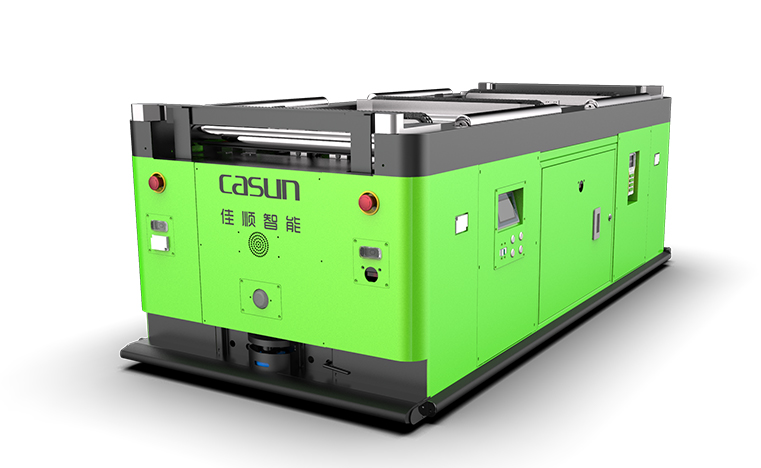

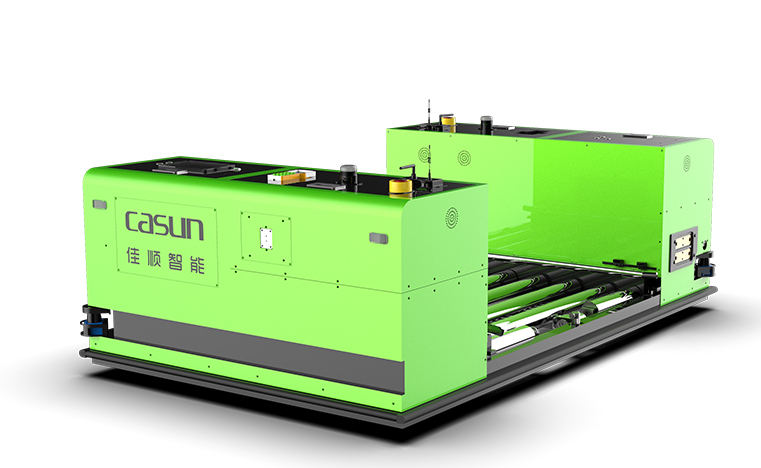

CCM-11 Customization AGV

CCM-11 Customization AGV

CCM-11 customized agv laseris customized for SMT production line, supporting customized navigation mode according to demand, which can realize the efficient end-to-end transfer of PCBA board materials at different heights, saving labor costs.

Parameters of CCM-11 Customized AGVCasun

|

Guidance |

QR code navigation/Laser navigation/SLAM navigation |

Lift height |

docking height is 250-1250mm |

|

Dimensions |

L1400*W700*H1450mm(docking height is 290-1250mm) |

Driving method |

Steering drive |

|

Traveling direction |

Forward, backward, rotation and sideways |

Charging method |

Auto charger(Side type) |

|

Load capacity |

100KG |

Battery |

Lithium battery |

|

Travel speed |

0~45m/min |

Safety detecting range |

≤3m(adjustable) |

|

Guidance accuracy |

±10mm |

Protections |

Front obstacle detection sensor+mechanical anti-collision bumper |

|

Stopping accuracy |

±10mm |

Core Advantages of CCM-11 Customized AGV

01

End-to-end transport

SMT customized AGV can connect production lines at different heights to realize intelligent distribution, turnover and warehousing of products, semi-finished products and finished products.

02

Replace artificial, intelligent and efficient

Equipped with intelligent navigation system, AGV transfers between different production lines, greatly improving the operation efficiency of the workshop.

03

Intelligent control, universal scheduling

The intelligent management system which is independently developed by Casun can realize the task of management, delivery and traffic control of all AGVs connected within the network; end customer can increase or decrease the number of AGVs at any time and support many types of AGVs in the same scenario.

As one of automated guided vehicle companies, we have types of products for sale, if you have needs, please contact us.

Send product request

Other supplier products

| C2-33 Omni-directional Latent Lifting AGV | C2-33 Omni-directional Latent Lifting AGV can move to the bottom of the material trolley, lift the material trolley and move to the destination. In... | |

| C3-42 Single Layer-four Conveyor Deck Load AGV | C3-42 is a single layer-four conveyor deck roller unit heavy load AGV, which can automatically dock with the production line or transmission line c... | |

| C5-P2 Balanced Forklift AGV | C5-Q2 is a balanced heavy laser navigation forklift AGV, AGV has no external legs, so there is no need to worry about the interference between the ... | |

| Latent Lifting AGV | Automated guided AGV lift carts could realize accurate self-positioning according to dispatched tasks and lift, transport as well as unload automat... | |

| C3-12 Single Conveyor Deck Load AGV | C3-12 single conveyor deck load AGV Trolley adopts loading rollers to connect the wiring edge equipment, and has the functions of in-situ rotation ... |

Same products

| SK222 Non Sparking Phillips Screwdriver | Seller: Hebei Sikai Safety Tools Manufacturing Co.,Ltd | SK222 Non Sparking Phillips Screwdriver Our non-sparking Phillips screwdriveris made from beryll... | |

| K238B Non-sparking Sledge Hammer | Seller: Hebei Sikai Safety Tools Manufacturing Co.,Ltd | K238B Non-sparking Sledge Hammer Non sparking sledge hammer is one kind of heavy-duty non sparki... | |

| PV Cleaning Vehicle | Seller: Trinabot Co., Ltd | The PV cleaning vehicleutilizes a cutting-edge leapfrog design structure, incorporating four-whee... | |

| YCX M9 Professional Screen Tester for True Tone and Refresh Rate Testing | Seller: Phonefix | YCX M9 Intelligent Screen Tester works with iPhone 6-16 Pro Max, Samsung, Huawei, Xiaomi, OPPO, V... | |

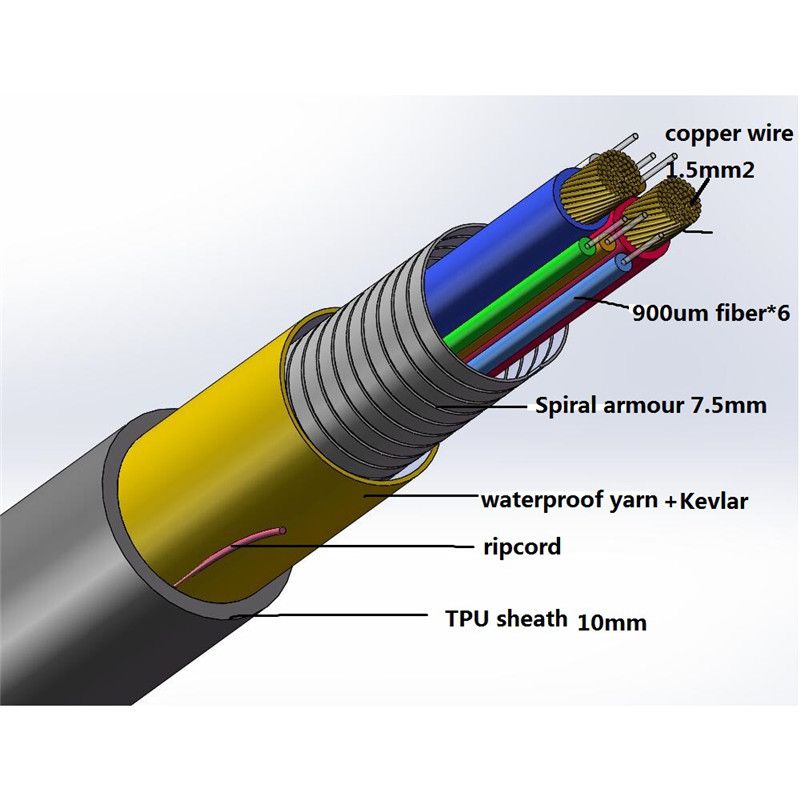

| copper fiber composite cable | Seller: Shenzhen Wirenet Telecom Technology Co., Ltd. | copper fiber composite cable Copper Fiber Composite Cable are hybrid cables that combine op... |