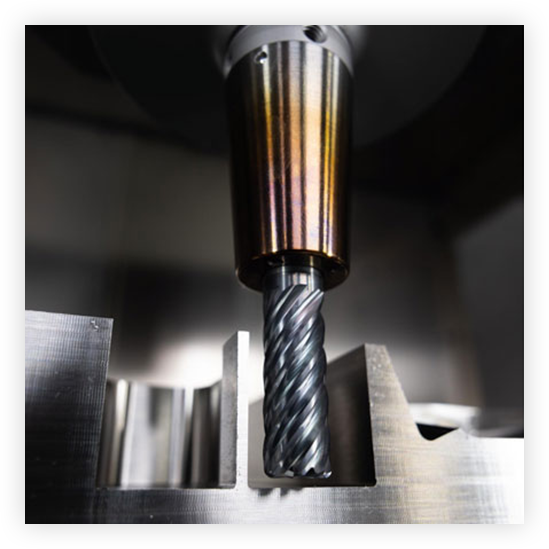

STATIC AND DRIVEN TOOLS

Static tool holderand driven tool holders are types of tool holder systems used in various machining applications, including milling, turning, and drilling. Static tools analyze code for potential flaws and errors without executing it, while mt driven toolsautomate the testing process by simulating user interaction with software. Both types of tools are important for ensuring the quality and security of software applications.

Purpose of Static and Driven Tools

Static tool holders are used to hold a fixed tool in a stationary position during machining operations. They are commonly used in turning centers where the tool is held in place while the workpiece rotates.

Driven mt live tool holders, on the other hand, are used to hold rotary tools that are driven by the machine's spindle. They are commonly used in milling centers where the spindle rotates the tool as it moves along the workpiece, allowing for complex profiles and contours to be machined.

Both static and tool drivenholders play important roles in modern machining operations, and the choice of which to use depends on the specific needs of the job and the equipment being used.

Purpose of Static and Driven Tools

How to keep Static and Driven Tools

Store them in designated holders or compartments to prevent damage

Clean and inspect regularly for signs of corrosion or wear

Remove any chips or debris from the holder

Tighten any screws or bolts regularly to maintain stability

Ensure proper installation and alignment

Operate the tool holder within recommended capacity and limits

As one of live tool holders manufacturers, we can provide kinds of coolant driven live toolingand mt live toolingfor sale, if you have needs, please contact us.

We bright toolsis a complete system supplier in the tool holding industry. With our systematic tool holder program, we offer a full line of high precision tooling system product portfolio. It comprises more than 8,000 size precision tool as rotating tool holders, stationary adapters, static and driven tools, boring tools and accessories. Our aim is to support tooling system for high precision and high efficiency machining.

Send product request

Other supplier products

| HSK・T Turning Tools for External and Cut-off | SBV facing turning toolholders are for external turning and cutting-off operation, with an adjustable cooling nozzle with internal thread. Due to i... | |

| Radial Holder Form B1 Right, Short | Radial Holder Form B1 Right, Short, as lathe accessory for CNC lathes, made of burnished case-hardened alloy steel, with square socket. The Radial ... | |

| Drill Chuck Adapter | A Drill Chuck Adapter is a tool used to adapt a drill chuck onto a machine with a different type of arbor. It is widely used in machine shops and f... | |

| STANDARD SHRINK FIT CHUCK 4.5° | WHAT ARE BENEFITS OF USING SHRINK FIT CHUCK 4.5°? The use of a Shrink Fit Chuck4.5° offers numerous benefits in machining operations. F... | |

| SHRINK FIT TOOL HOLDER | SHRINK FIT TOOL HOLDERS SERVICE LIFE The Shrink Fit Tool Holder is a unique piece of equipment that requires the use of a heating machine for opti... |

Same products

| SK222 Non Sparking Phillips Screwdriver | Seller: Hebei Sikai Safety Tools Manufacturing Co.,Ltd | SK222 Non Sparking Phillips Screwdriver Our non-sparking Phillips screwdriveris made from beryll... | |

| K238B Non-sparking Sledge Hammer | Seller: Hebei Sikai Safety Tools Manufacturing Co.,Ltd | K238B Non-sparking Sledge Hammer Non sparking sledge hammer is one kind of heavy-duty non sparki... | |

| STATIC AND DRIVEN TOOLS | Seller: Shandong Jinjie Machinery Co.,Ltd | Static tool holderand driven tool holders are types of tool holder systems used in various machin... | |

| ETONG Electric Utility Vehicle | Seller: Guang Dong Etong New Energy Technology Co., Ltd. | ETONG Electric Utility Vehicle Equipped with unique and individual operation system, agile and s... | |

| Pot Magnets | Seller: Neomag Ltd | Pot magnets (also called Cup magnets, Mounting magnets) consist of magnets encased in a steel cup... |