Grinding Machine

1. Gantry Type Surface GrinderFeatures:• SIEMENS touch operation panel • Z-axis: Rectangular guideway; Y-axis: precision linear guideway (HIWIN, Taiwan)• Hydro-static & hydro-dynamic spindle or roller bearing spindle can be choosed as clients’ needs.• The horizontal and vertical grinding head could be designed in the same beam, or two different beam.• Semi-closed splash guard.ModelSG-5312SG-5316 Worktable sizeWidth1200mm1600mm Length2000~7000mm2000~7000mmMachining capacityWidth1400mm2000mm Length2000~7000mm2000~7000mm Height1000mm1000mm Gantry width1600mm2200mm Horizontal spindle motor22kw22kw Horizontal spindle speed1050r.p.m1050r.p.m Min. feeding0.005mm0.005mm Horizontal wheel sizeΦ600×100×Φ305mmΦ600×100×Φ305mm Vertical spindle motor11.5kw11.5kw Vertical spindle speed800~2500r.p.m800~2500r.p.m Min. feeding0.005mm0.005mm Swivel of grinding head±100°±100°2. Column Moving Surface GrinderFeatures:• Double walled column construction, providing high rigid support. Adopt counterweight balance, making the machine moving stably, and reducing the load of the ball screw, keeping the accuracy for long time.• Adopt rectangular guideway coated with ZA30-C zinc-based alloy, to get low friction coefficient, good abrasive resistance and high rigidity.The wheelhead spindle use the hydrostatic bearing with high rigidity(high precision ball bearing for export), which can provide the power force together with 18.5kw motor, suitable for the heavy machining. The spindle rotary is supported by rigidity oil layer without wear, ensure the high precision and long life span.• Adopt the Flat-V type guideway to set good guidance quality on longitudinal and transverse, precision scraping to keep stable work accuracy by hand.• The transverse and vertical movement are driven by AC servo motor, and the electronic hand wheel(MPG) instead of the tradition mechanical hand wheel, to get high accuracy and easy operation.• The independent and large capacity integrated hydraulic station equipped with air cooling and pressurizer, isolate heat and vibroseis, to provide excellent power for precision grinding.• Hydraulic drive for the work table, after adjusting meticulously, the table moved stably with little impact.• Adopt SIEMENS touch operation panel. It makes the operation simple and interesting by using power and friendly human-machine interface.Specification Unit SG-81160FR SG-81220FR SG-81300FR SG-100220SD SG-10300FR Working Area Table size (W × L)mm810×1600810×2200810×30001000×22001000×3000 Max. grinding dimension (W × L)mm810×1600810×2200810×30001000×22001000×3000 Max. spindle to table distancemm900 (1150) Electro magnetic chuck (optional)mm800×800×2800×1000×2800×1000×31000×1000×21000×1000×3 Max. loading capacity ( include chuck)kg 3 axis feed Table longitudinal movement speedm/min5~25 Wheel head Auto. feedmm/t1~30 cross movement Rapid speedm/min0.05~3 Feed of electro handwheelmm/gr0.005 Wheel head Auto. feedmm/t0.005~0.05vertical movement Rapid speedm/min0.05~2 Feed of electro handwheelmm/gr0.005 Grinding wheel Speed rpm960 Size ( OD × W × ID)mm500×75×305500×75×203 Motor Spindle motorkw18.5 Hydraulic pump motorkw7.5 Elevating servo motor and cross feed servo motorkw3 Total rated powerkw34 Dimensions and Weight Floor space (L × W)mm4700×40006000×40008200×40006000×43008200×4300 Gross Weightkg. Wheelhead Moving Surface GrinderFeatures:• The slide way with the TF wearable belt, and have been precision manual scraped. Only by this, the machine have high accuracy and smooth moving and long using life.• Double wall structure casting is adopted on Column. And between outside and inside wall have strengthen rib. The well designed structure have good rigidity and keep the machine with high accuracy.• The spindle is made in Taiwan, by famous specially manufacturer. high load resistible, mounted in pre-loaded angular deep-groove ball bearing ensures low-vibration operation, high accuracy, increased lifetime, and low maintenance• Well designed and carefully assembled Hydraulic unit make the table moves smoothly. The oil temperature increase low after long working.***Standard accessories:Wheel chuck, Wheel balancing arbor, Wheel extracting units, Coolant tank, Work light, Tool box & tools,Wheel dresser rest (without diamond pen), Standard wheel, leveling wedges and foundation, electromegneticchuck, Operator manual in English.SpecificationUnitGS-300AGS-300BGS-300CGS-320AGS-320BGS-320CGS-400AGS-400BGS-400CGS-500AGS-500BGS-500CGS-630AGS-630BGS-630C Worktable size Widthmm Lengthmm1000/1600/2200/3000/45001000/1600/2200/3000/45001000/1600/2200/3000/45001000/1600/2200/3000/45001250/1600/2200/3000/4500 Max processing dimension Widthmm Lengthmm1000/1600/2200/3000/45001000/1600/2200/3000/45001000/1600/2200/3000/45001000/1600/2200/3000/45001250/1600/2200/3000/4500 Heightmm Max. distance between spindle center line and worktable surfacemm Longitudinal moving speed of worktablem/min3~273~273~253~273~27 T-slot number/widthpcs*mm3*183*183*183*223*22 Wheelhead cross moving Consecutive feed speedm/min0.5-4.50.5-4.50.5-4.50.5-4.50.5-4.5 Intermittent feed speedmm/t3~303~303~303~303~30 Hand wheel feedMm

/gra 0.020.010.01 Wheelhead vertical moving Rapid feedMm

/min Hand wheel feedMm

/gra0.0050.0050.0050.0050.005 Wheelhead motor Powerkw5.55.57.57.57.5 Rotation speedr.p.m Total powerkw9/119/1111/13.5/15.7512.25/13.75/15.7513.75/15.75 Max. loading capacity of worktable(with chuck)kg470/750/1030/1400/2100500/800/1100/1500/2250620/1000/1380/1872/2810700/1240/1410/1930/28951010/1290/1780/2430/3650 Wheel size(OD*W*ID)mm350*40*127350*40*127400*40*127400*40*203400*40*203 Overall dimensionLengthmm2860/4250/5750/7880/121702860/4250/5750/7880/121703110/4250/5750/7880/121703110/4250/5750/7880/121703300/5320/5750/7880/12170WidthmmHeightmm. Saddle Moving Surface GrinderFeature:• Slide way:The slide way with the TF wearable belt, and have been precision manual scraped. Only by this, the machine have high accuracy and smooth moving and long using life.• Spindle Unit:The high precision spindle unit is well designed and produced. high load resistible, mounted inpre-loaded angular deep-groove ball bearing ensures low-vibration peration, high accuracy, increased lifetime, and low maintenance.• Lead Screw:The vertical lift lead screw is made in Taiwan, Name: SHYH MINMACHINERY. The Cross feed screw is Ball screw( SG-30~40 series), make sure the smooth moving. AC motor drove the cross screw by timing belt then realize autointermittent feed.• Motor:The spindle Motor, Y axis drove Motor, and other important parts, Are all made by famous specialty manufacturer, SHVH MIN,Juli, Shuanglin etc.• AHD model ( with AUTO down feed)For AHD model, the spindle elevating motor adopt Servo motor made in Japan ( Panasonic), and controlled by Siemens PLC.The operator can set the Auto working (feed rate and times, spark grinding times by the control panel. When finish grinding, the spindle will lift up auto.The wheel guard with micro switch, even the door is opened, the spindle would be power off (only for AHD)• Electrical system:The electro system have been designed according to the CE standard All the electro parts adopted world famous brand, such as the Siemens, schneider, etc.Standard Accessories:Wheel chuck, Wheel balancing arbor, Wheel extracting units, Coolant tank, Work light, Tool box & tools, Wheel dresser(without diamond pen), Standard wheel, Leveling wedges and foundation, Electric magnetic chuck, PLC auto. grinding controller(only for AHD model), Operation manual(English edtion).Optional Accessories:Wheel balancing stand, Parallel dresser, Cooling system with paper filter, Cooling system with magnetic separator, Cooling system with magnetic separator & paper filter.Specification Unit SG-2050AH SG-2550AH SG-3063AH SG-30100AH SG-4080AH SG-40100AH SG-2050AHR SG-2550AHR SG-3063AHR SG-30100AHR SG-4080AHR SG-40100AHR SG-2050AHD SG-2550AHD SG-3063AHD SG-30100AHD SG-4080AHD SG-40100AHD Table size (W×L)mm200x460250x500305x635305x1020406x813406x1020Longitudinal travelmmCross travelmmMax. distance from spindle to tablemmElectro magnetic chuck sizemm200x460250x500300x600300x1000400x800400x1000Speed of table longitudinal movem/min7~23Table cross movementAuto feedmm0.1~8Rapid feedmm/min990Handwheel feedmm/div0.02Wheelhead vertical movementAuto feedmm0.005/0.01/0.02/0.03/0.04/0.05 (Only for AHD series)Rapid feedmm/min460 (Only for AHR/AHD series)Handwheel feedmm/div0.005Grinding wheelSpindle speedrpm50HZ: 2850 / 60HZ: 345050HZ: 1450 / 60HZ: 1750Wheel sizemm200x 20 x31.75350x40x127Spindle motorkw1.52.25.5Hydraulic pumpkw0.752.2Cooling pumpkw0.040.125Elevating motorkw0.25 (AHR model) / 0.5 (AHD model, Servo motor)Cross feed motorkw0.04Total rated powerkw33.79Max. loading capacity (include chuck)kgHeight of the machinemm16751890Floor space (L×W)mm2050x14002300x16502900x22004400x22003600x24004400x2400Gross weightkgPackage size (L×W×H)cm190x172x218200x210x218235x222x215295x222x221285x227x218295x227x2215. Manual Surface GrinderFeatures:• Spindle adopts ultra precision P4 ball baering ,after measuring pre strict pressure,assembled in the greenhouse,and equipped with a completely waterproof mazy design,in order to ensure the service life and the grinding of bearing surface roughness.Which marching with ball screw.• .It has the advantages of compact structure,easy to operate.• A longitudinal guide rail worktable adopts rolling guide,rope wheel traction,light and flexible.Specification Unit HSG-618 HSG-820 HSG-1022 HSG-1224 HSG-1230 HSG-1232 BenchMax.workpiece to be ground(L*W)mm460*180480*200540*250600*300700*300800*320Max.travel of table(L*W)mm500*190520*220560*260640*320760*370860*320Table Max.cutting area(L*W)mm500*190520*200540*250640*320760*370860*380Number/Wide of T-slotmm1*121*141*141*141*141*14The Grinding headDistance from table surface to spindle centermmWheel size(Dia.*Width*Bore)mmΦ200*20*Φ31.75Φ200*20*Φ31.75Φ200*20*Φ31.75Φ250*25.4*Φ76.2Φ335*30*Φ127Φ335*30*Φ127Spindle speedrpmThe amount of feedTable longitudinal(left and right)speed(stepless)m/minTable horizontal(before and after)the amount of feedContinuous(variable speed)mm/minIntermittent(stepless)mm/timeThe handwheel rotatesmm2.52.54444Hand wheel each gridmm0.020.020.020.020.020.02Vertical(up and down)feed wheel feedThe handwheel rotatesmm1.251.252222Hand wheel each gridmm0.010.010.010.010.010.01Motor powerSpindle motorkw1.51.51.52.244Cooling motorwHydraulic systemHydraulic motorkw1.51.51.51.51.51.5Working pressureMpa333333Oil tank capacityLMax.capacityL/minWorking precisionThe machined surface of the base of parallelismmm0.005/3000.004/3000.004/3000.004/3000.004/3000.004/300Surface roughnessumRa0.32Ra0.32Ra0.32Ra0.32Ra0.32Ra0.32Weight of machineNetT0.811.051.251.52.12.5GrossT0.851.151.351.652.352.75Packing size (L*W*H)mm1080*1190*18701680*1140*17201780*1220*17801960*1630*18701990*1700*19902000*1800*20006. Cylindrical GrinderFeatures:• The table longitudinal traversal is actuated by hydraulic means at step lessly variable speed or operated by means of hand wheel. • The wheel head rapid approach and withdrawal and intermittent feed are effected hydraulically,the wheel feed can also be operated by hand.• The wheel head cross feed is driven by hydraulic, which realizes automatic periodical feed and rapid feed. It can also do rough and feed feed through hand wheel.• The work table and wheel head guide way of the UG-500 series adopt hydrostatic lubrication,its movement on low speed is smooth.• The spindle of UG-500 series is supported by hydrostatic and hydrodynamic bearings of high rigidity, it makes the spindle have high rotary accuracy and perfect rigidity.• The work head adopt inverter motor to realize variable speed changing. The work head can be rotate to any position within its anticlockwise direction 90°, so it can be suitable for grinding inner or outer surface of taper.***Standard accessories:Coolant tank, Wheel periphery dresser base (without diamond pen), Flange and wheel extractor, Standard grinding wheel, Balancing arbor,Working lamp, Leveling wedge, Open steady rest, Internal grinding device***Optional accessories:Balance stand, Magnetic separator apparatus, Paper filter apparatus, Center grinding attachment, Close steady rest, End wheel dresser, Radius (arc) wheel dresserSpecification Unit UG-200 UG-320 UG-500 UG-630 *General capacityDistance between centersmm500, 7501000, 1500, 2000, 30001500, 2000, 3000, 40002000, 3000, 4000, 5000Center heightmmDia. Ground (O.D)mmDia. Ground (I.D)mmMax. length ground (O.D)mm500, 7501000, 1500, 2000, 30001500, 2000, 3000, 40002000, 3000, 4000, 5000Max. length ground (I.D)mmMax. weight of workpiecekg* Work headSwiveling angle°﹢90°﹢90°﹢90°﹢90°Center taper (MT)MT4466Spindle speedr/min50HZ: 25-380 Stepless50HZ: 25-220 Stepless50HZ: 20-224 Stepless50HZ: 14-140 Stepless* Wheel headWheel spindle speedr/min/6651100/550Wheel head rapid travelmm5050100100Max. travelmmSwiveling angle°±30°±30°30°±30°Hand feed per.revmmrough:2, fine:0.5rough:2, fine:0.5rough:4, fine:0.5rough:4, fine:0.5Hand feed per.grammrough:0.01, fine:0.0025rough:0.01, fine:0.0025rough:0.02, fine:0.0025rough:0.02, fine:0.0025Wheel size (ODXWXID)mm400x50x203400x50x203500x75x305600x75x305Peripheral velocitym/s353535/17.535/17.5* Internal grinding deviceSpindle speedr/min10000/1500010000/Dimension of wheelmmMax:50x25x13, Min:17x20x6Max:175x32x32, Min:30x25x10* TableHand feed per.revmm5Max.swiveling angle of tableClockwise°3°3° (1000, 1500), 2° (2000, 3000)3° (1500), 2° (2000, 3000), 1°(4000) 2° (2000), 1°(3000, 4000, 5000)Anticlockwise°9° (500), 8° (750)7° (1000), 6° (1500), 5° (2000), 3° (3000)6° (1500), 5° (2000), 3° (3000), 2°(4000)4° (2000), 3° (3000), 2.5°(4000), 1.5°(5000)Table Longitudinal speed rangem/min0.1-40.1-30.1-2.5* TailstockCenter taper (MT)MT4466Quill travelmm30307070* MotorWheel head motor powerkw45.55/7.57/11'Internal grinding motor powerkw1.11.11.51.5Work head motor powerkw0.751.5415* MachineGross weightT4.1 (500), 4.3 (750)5.3 (1000), 6.1 (1500), 7.9 (2000), 9.9 (3000)11.2 (1500), 13 (2000), 17.4 , 22(3000), 24(4000), 26(5000)7. Vertical Spindle Surface GrinderKey Feature:• The surface grinder with vertical spindle and round table is to grind the end face of grinding wheel, is a high efficiency, precise and stable machine tools.• With electronic oil pumping system, oil volume is adjustable.• Upright post adopts three-point adjustment, compact structure,worktable is round powerful electromagnetic chuck, and equips with coolant device.• Surface roughness reaches above 0.8,and parallelism is within 0.02/1000mm.• It is especially suitable for grinding of large parts in metallurgy, saw blade, automobile, tractor, tools, bearing and other industries. Standard Configuration: Coolant tank, Electromagnetic chuck, 2-axis digital indicator, Wheel dresser, working lamp, Leveling wedge and bolt, tool and tool box, Operation manual in English. Model M7475 M7480 M74100 M74125 Diameter of worktableΦ750mmΦ800mmΦ1000mmΦ1250mm Suction range of electromagnetic chuck80-120M/cm²80-120M/cm²80-120M/cm²80-120M/cm² Max. size of workpiece ground (Dia.×height)Φ750×320mmΦ800×320mmΦ1000×400mmΦ1250×400mm Size of grinding segment (Thickness×width×length)125×85×35mm125×85×35mmWP25×80×150mm125×85×35mm Speed of worktable rotation13, 20rpm13, 20rpm12, 24rpm12, 24rpm Distance of worktable movement450mm450mm570mm675mm Speed of worktable movement4m/min4m/min3.7m/min3.7m/min Power of worktable rotary motor2.2kw2.2kw2.4kw2.4kw Power of worktable movement1.1kw1.1kw1.1kw1.1kw Spindle speed of grinding head940rpm940rpm740rpm740rpm Rapid speed of grinding head0.22m/min0.22m/min0.15m/min0.15m/min Motor power of grinding head25kw25kw45kw45kw Elevating motor power of grinding head0.55kw0.55kw0.55kw0.55kw Wheelhead vertical movement of handwheel feed0.5mm0.5mm0.4mm0.4mm Wheelhead vertical movement of dial indicator0.01mm/div0.01mm/div0.01mm/div0.01mm/div Wheelhead vertical movement of dial indicator1.0 mm/r1.0mm/r1.0 mm/r1.0mm/r Power of coolant pump motor0.25kw0.25kw0.25kw0.25kw Total rated power30kw30kw50kw65kw Machine Weight (approx.)6000kg6000kg7500kg8500kg

Other supplier products

|

|

Grinding Machine |

1. Gantry Type Surface GrinderFeatures:• SIEMENS touch operation panel • Z-axis: Rectangular guideway; Y-axis: precision linear guideway (HIWIN, T... |

|

|

Deep Hole Tools |

Deep Hole Tools,Website: Hole Equipment |

|

|

Deep Hole Drilling & Boring Machine |

1.CNC Deep Hole Boring and Drilling Machine -- DBK-100Application:●CNC deep hole drilling and boring machine is mainly for the processing of cylind... |

|

|

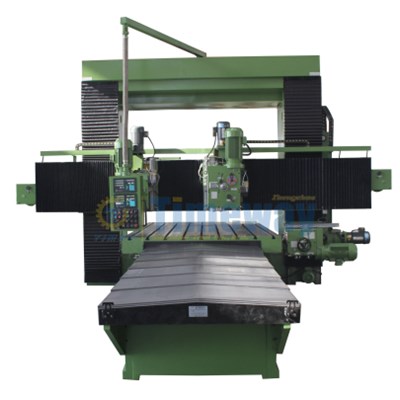

Milling Machine |

1.Gantry Type Milling MachineApplication:• M20 series heavy gantry milling machines are high-tech products with high working efficiency.The core te... |

|

|

Drill Tools |

Drill Tools,Website: Field Euipment |

All supplier products

Same products