SL TEC Formaldehyde Plant

SL TEC has close to ten years experience in based on silver contact process(or silver catalyzed process). A lower methanol consumption, higher formalin product concentration, high export steam capacity and ease of operation are our features, which makes it the best technical and economically viable solution.

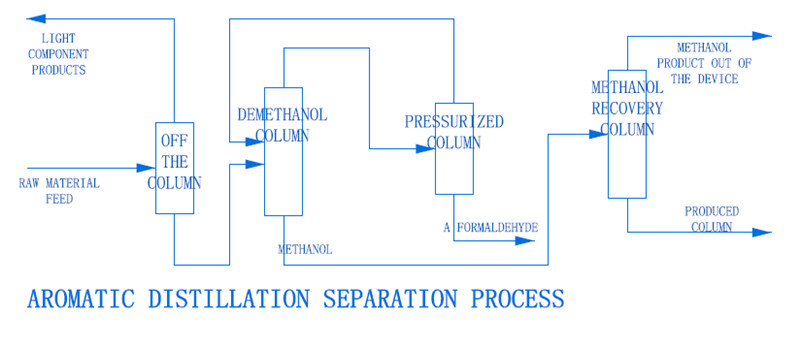

Every unit operation incl. methanol evaporation, catalytic reaction, absorption, off-gas treatment has optional design to at best satisfy the customer’s needs.

We provide one-stop package solutions from the , manufacture, erection, commissioning, startup to training, with the production capacity of 6,000TPA – 120,000TPA and the formaldehyde product concentration varying from 37-55%. And according to the customer’s different needs, there are totally 7 (seven) optional processes as follows:

1) Traditional Bubble Evaporator + Absorber with 3 (three) Concentration Gradients to produce 37% formalin

2) New Evaporator + Absorber with 3 (three) Concentration Gradients to produce 37% formalin

3) Off-gas Circulation + Re-boiler + Absorber with 3 (three) Concentration Gradients to produce 37-42% formalin

4) Off-gas Circulation + Re-boiler + Absorber with 3 (three) Concentration Gradients to produce 37-55% formalin

5) Off-gas Circulation + Evaporation Column + Absorber with 6 (six) Concentration Gradients to produce 37-55% formalin

6) Off-gas Circulation + Multipurpose Evaporator + Absorber with 6 (six) Concentration Gradients to produce 37-55% formalin

More information please via:

Send product request

Other supplier products

| Formaldehyde Plant | Formaldehyde Plant SL TEC has close to ten years experience in formaldehyde production technology based on silver contact process(or silver ca... | |

| Hydrogen Peroxide Manufacturing Plant | There are several methods for, among them theAO(auto-oxidation) processis the most prevailing one. In this process, 2-alkyl anthraquinone is mixed... | |

| SL TEC Formaldehyde Plant | SL TEC has close to ten years experience in based on silver contact process(or silver catalyzed process). A lower methanol consumption, higher for... | |

| ECH production process by glycerin method | Epichlorohydrin is the main raw material for the production of epoxy resin. It is also an important organic chemical raw material and fine chemica... | |

| Proprietary Technology and Plants China | Concentrated Recycling Technology of Formaldehyde Proprietary Technology and Plants Technical Features: In the production of paraformaldehyde an... |

Same products

| Peptide Technology Cooperation & Transfer | Seller: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

| Recombinant Human Fibroblast Growth Factor-basic | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

| Recombinant Staphylococcal Protein A | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |