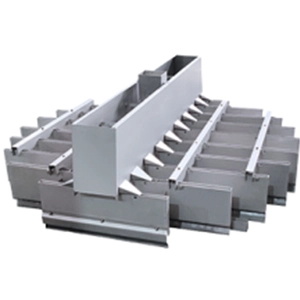

Column Internals

Columns Internals

A strict quality management system guarantees the product quality and delivery time of the project.

Characteristics of Packed Column Internals, Packed Column Internals

1

Liquid distributors with liquid load from 0.01m3/m2h to more than 200m3 / m2h;

2

High operating turndown and suitable for fouling systems including suspension, emulsion and dust. Both gas and liquid can be distributed well;

3

Different types of gas distributors and flash feed systems according to different gas velocities;

4

Different types of collectors according to different applications, such as vane collectors, chimney tray collectors, collectors/redistributors, etc;

5

Different types of support grids ( for structured packing & random packing);

6

Three-in-one distributors(support grid + collector + distributor);

7

DODGEN has a 16 * 16m distributor test platform.

Applications of Column Internals

Chemical industry: OLEO, flavors & fragrances, Ethylbenzene (EB) / Styrene Monomer (SM), cyclohexanone / cyclohexanol, air separation

Petrochemical Industry: quench tower, C3 and C4 separation tower, xylene separation tower

Oil refining unit: Crude Oil tower, vacuum tower

Absorption and desorption: natural gas dehydration, CO2 and H2S absorption and stripper, ethylene oxide(EO) absorption and stripper, acrylonitrile absorber

If you want to know more about tower internals, please visit our website.

As one of column internals manufacturers, we will do our best to meet all the needs of customers.

As a chemical processingcompany, DODGEN is committed to becoming a specialist in advanced materials and green process technology. We are dedicated to working rigorously with all clients in the new material, new energy, and green manufacturing industry of chemicals, creating value and success.

Send product request

Other supplier products

| Hydrocyanic Acid (HCN) Process Technology | Process optimization and improvement in reaction, a new generation of hydrocyanic acid synthesis technology in the world. Characteristics of hyd... | |

| Gas-liquid Separator | Complete liquid nitrogen separatorproduct chain has been considered to customize separation scheme for customers. Technical principle Of gas liq... | |

| Melt Crystallizer | Accurately control the temperature and integrate a number of technologies for efficient purification. Characteristics of Melt Crystallizer 1 H... | |

| Distillation Technology | Technical Principle Of Technology Distillation distillation technology Gas-liquid two-phase contact through countercurrent for interphase heat an... | |

| Continuous Flow Reactor | A continuous flow reactor, continuous flow microreactoris a reactor in which a chemical reaction takes place in a continuous stream of fluid or gas... |

Same products

| Peptide Technology Cooperation & Transfer | Seller: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

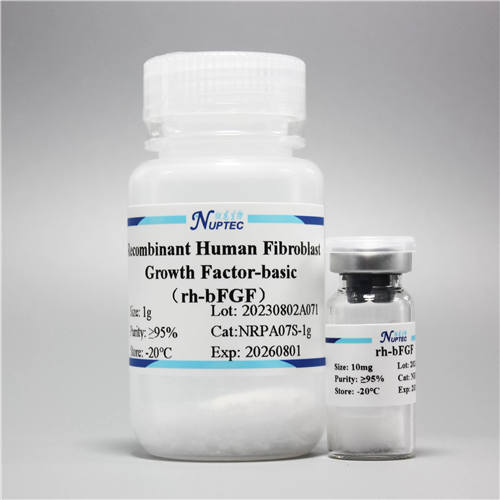

| Recombinant Human Fibroblast Growth Factor-basic | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

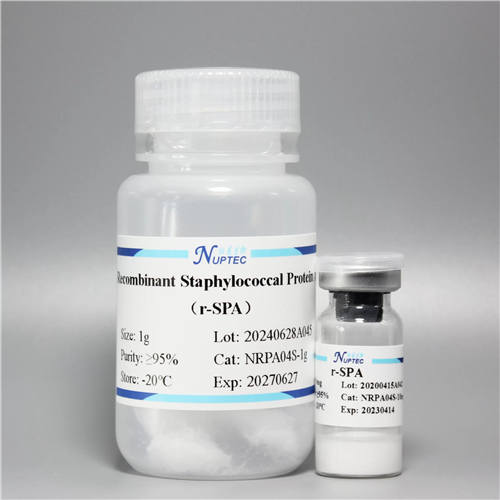

| Recombinant Staphylococcal Protein A | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |