Continuous Flow Reactor

A continuous flow reactor, continuous flow microreactoris a reactor in which a chemical reaction takes place in a continuous stream of fluid or gas. Unlike batch reactors, which operate on a cycle, continuous flow reactors carry out a process on a steady-state basis. These reactors are widely used in the chemical and pharmaceutical industries, where they offer a more precise control of reaction conditions and better safety by limiting the accumulation of hazardous substances. They are known for their high productivity, better selectivity, and energy efficiency.

Types of Continuous Flow Reactor

Static Mixer

Polymerization Reactor

Micro Reactor

What Are The Institutional Components Of A Continuous Flow Reactor?

A continuous flow reactor designis a device in which chemical reactions are carried out continuously. During the reaction process, the reactants and solvent flow continuously and complete the chemical reaction process simultaneously. A continuous flow reactor consists of: stirring, mixing (or heating) system, temperature control system and other components.

What Are The Advantages Of Continuous Flow Reactors?

If you want to know more about continuous flow reactor technologyand continuous flow reactors working principle, please visit our website.

As a chemical processcompany, DODGEN is committed to becoming a specialist in advanced materials and green process technology. We are dedicated to working rigorously with all clients in the new material, new energy, and green manufacturing industry of chemicals, creating value and success.

Send product request

Other supplier products

| Melt Crystallization | Accurately control the temperature and integrate a number of technologies for efficient purification. Technical Principle Of Melt Crystallizatio... | |

| Hydrocyanic Acid (HCN) Process Technology | Process optimization and improvement in reaction, a new generation of hydrocyanic acid synthesis technology in the world. Characteristics of hyd... | |

| Melt Crystallizer | Accurately control the temperature and integrate a number of technologies for efficient purification. Characteristics of Melt Crystallizer 1 H... | |

| Micro Reactor | Technical Principle Of Micro ReactorComposition of D-AMERT high flux microreactor:Transfer metering unit —Temperature control unit—micr... | |

| Continuous Flow Reactor | A continuous flow reactor, continuous flow microreactoris a reactor in which a chemical reaction takes place in a continuous stream of fluid or gas... |

Same products

| Peptide Technology Cooperation & Transfer | Seller: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

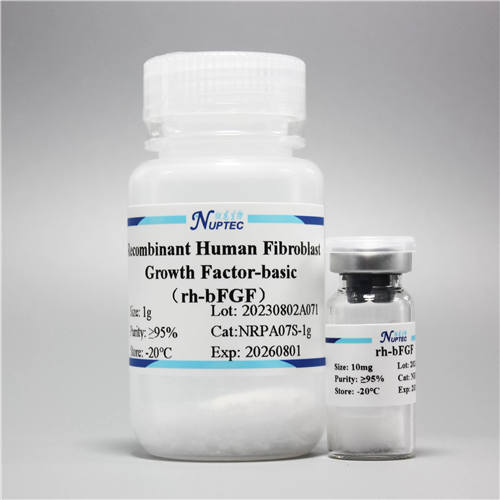

| Recombinant Human Fibroblast Growth Factor-basic | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

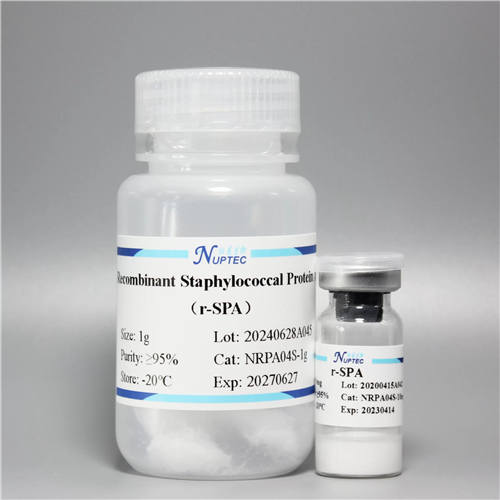

| Recombinant Staphylococcal Protein A | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |