HaiStation

In the complete Goods to Person solution, HaiPickorder picking robotsare dedicated to improving transport efficiency from warehouse to workstation. Hai Robotics also developed HaiStation, which is used to improve the efficiency of robotic workstationsto order cases.By combiningtheorder picking robotwith HaiStation, overall efficiency is significantly improved.

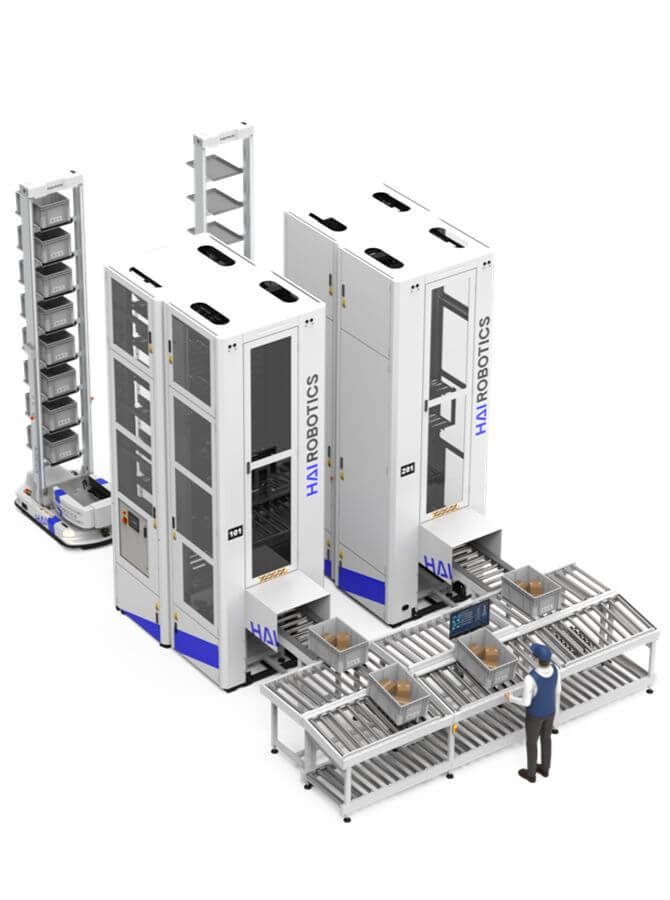

HaiStation is a product portfolio that is composed of including HaiPort workstation, conveyor, put wall, buffer wall, workstation, robotic arm, etc. As the backend of the whole warehouse solution, HaiStation provides ultra-efficient case loading and unloading connections to frontend robots with safe human-robot interactions.

Why HaiStation

why choose haistation

Efficient

Enables more efficient loading and unloading of cases. Significantly increases HaiPick ACR's efficiency.

Safety

Fully automated inbound and outbound logistics. Workers and robots are separated to run processes in a secure way.

Friendly Design

Ergonomic picking system design provides a seamless human-to-system interaction, providing maximum in-and-outbound efficiency.

HaiPort-powered Workstation

HaiPort-poweredworkstationis an automatic loading and unloading machine. It is composed of HaiPort, conveyor, visual Kanban, put wall, pick to light system, and can easily dock with HaiPick ACR to automatically unload, transport, and load cases from the robot's storage tray, optimizing inbound and outbound processes.

The workstation enables more efficient loading and unloading of cases. It can load 8 cases in 3 seconds and unload 8 cases in 5 seconds, which significantly increases HaiPick ACR's efficiency.

Its modular design, flexibility, and easy transport capabilities support rapid increase/decrease of equipment, meeting high efficiency and low cost requirements. Workers and storage robots are separated to ensure safety. The ergonomic design of the on-robot picking workstation delivers convenient operation, high efficiency, and low cost.

High Efficiency

Handles up to 8 cases at once – fully loading / unloading handoffs in seconds.

Best and Fastest

Loads 8 cases in 3 seconds, unloads 8 cases in 5 seconds.

Human-robot Cooperation

With an ergonomic design, HAIPICK robots and workers are indirectly connected.

400% Faster

Reduced loading and unloading time by 80%.

Efficient Deployment

Modular design ensures easy deployment and redeployment when changing warehouse workstation layouts.

Product Safety

CE /NRTL certified.

Seeing is Believing

Video: Explore How Our Robotics Warehouse Workstations Streamline Operations with Maximum Efficiency

Looking to improve warehouse efficiency and productivity? Check out Hai Robotics' video showcasing their cutting-edge robotic workstations. From conveyor workstation to HaiPortwarehouse work station, our systems automate and optimize workflow, reducing errors and streamlining operations. With seamless integration and customization options, our warehouse workstationcan enhance order picking, inventory management, and more. Upgrade to the latest technology and experience the benefits of robotics warehouse automation today!

On-conveyor Picking Workstation

The on-conveyor workstationautomatically conveys the cases unloaded by the HaiPick robot or the cases that need to be loaded, realizing automated storage and retrieval functions. It is composed of a conveyor line, visual Kanban, shelves, and pick to light system.

It offers an ergonomic design, the workers and HaiPick robots are indirectly connected, and the goods can be sorted on the conveyor line without too much movement. It delivers convenient operation and efficient warehousing.

Intelligent Sorting

The visual system Kanban manages work, guiding workers to sort goods more efficiently.

Easy to Operate

The worker can finish picking goods on the conveyor line without walking or moving.

Safe & Comfortable

Ergonomic design that allows safer and comfortable operations.

High Efficiency

Each robot can transport 25 – 30 cases/h for inbound operations and 25 – 30 cases/h for outbound operations, and the maximum efficiency of a single workstation can reach 300 cases/h.

Send product request

Other supplier products

| 12 Benefits of Warehouse Automation | Warehouse automationsolution is an integral part of optimizing supply chains as it reduces time, effort, and errors caused by manual tasks. Today, ... | |

| HAISTATION | In the complete Goods to Person solution, HAIPICK robots are dedicated to improving transport efficiency from warehouse to workstation. HAI ROBOTIC... | |

| Industry Solutions Using robotics to promote the progress of humanity | Fashion With the trend of the global fashion industry strengthening, the supply chain is facing more and more challenges. Companies are becoming... | |

| Multi-Layer ACR | HAIPICK A42 The A42-series offers picking and storage of cases up to a height of 5.2m (17.1 feet). The series consists of four models which handle... | |

| Automotive | The diversification of order-driven production and rising labor costs are posing significant challenges to the traditional mode of warehousing logi... |

Same products

| Raspberry Pi CM5 Embedded Computer No.BL460 | Seller: BLIIOT | Industrial AI Embedded Computer BL460 based on the Raspberry Pi CM5 module and compatible with th... | |

| 4*A76 RK3588 ARM Based AIoT Edge Computer No.BL450 | Seller: BLIIOT | BL450 is a fanless AI computer and industrial PC built on the Rockchip RK3588J/RK3588 with quad-c... | |

| 4*A72 RK3576 ARM Based Mini Industrial Computer No.BL440 | Seller: BLIIOT | BL440 is an ARM based industrial PC from the ARMxy series, built on Rockchip RK3576J/RK3576 with ... | |

| 4*A55 RK3568 Fanless ARM Industrial PC No.BL410 | Seller: BLIIOT | BL410 is a fanless ARM industrial PC powered by the RK3568J/RK3568B2 with quad-core Cortex-A55 up... | |

| 4*A53 RK3562J Linux ARM Edge Computer No.BL370 | Seller: BLIIOT | BL370 Linux ARM computer built on Rockchip RK3562/RK3562J with quad-core Cortex-A53 and Cortex-M0... |