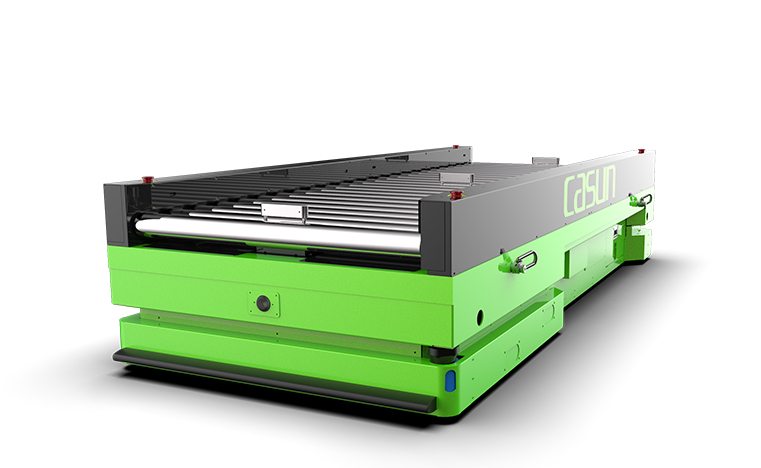

C2-31 Omni-directional Latent Lifting AGV

C2-31 Omni-directional Latent Lifting AGV can move to the bottom of the material trolley, lift the material trolley and move to the destination. In addition, the lift AGV also has an in-situ rotation function. You can choose QR code navigation or magnetic strip daohang according to the on-site environment.

Core Advantages of C2-31 Omnidirectional Latent Lift AGVEquipment

01

Flexible mobility

90-degree corner or 180-degree in-situ rotation & U-turn or lateral movement can work in narrow spaces.

02

Multiple navigation modes

According to different application scenarios, two-dimensional code navigation or magnetic stripe navigation can be selected.

03

Lifting control

It can interact with the elevator to complete the operation of automatically going up and down floors.

04

High positioning accuracy

The primary positioning accuracy can reach ±10mm, and the secondary positioning accuracy can reach ±5mm.

05

High work efficiency

Equipped with a full servo drive, it can increase the speed quickly (0-72 meters per minute only takes 3 seconds), and has a fast rotation function (only 3 seconds for in-situ rotation)

06

Multi-AGV linkage

Synchronous linkage of multiple AGVs is suitable for complex material handling scenarios.

07

Automation and labor saving

No manual intervention is required in the production process, and the scheduling system is fully automatic.

08

Fault self-check

With fault self-checking function, remote fault diagnosis and self-recovery function.

09

Automatic battery charging

When the automated guided vehicle chinadetects a low battery state, it will automatically move to the charging station for charging. The online time can reach 24 hours a day to improve productivity.

10

Multiple security protection

Equipped with laser obstacle detection sensor, mechanical anti-collision device and sound and light warning to ensure safe operation.

If you want to buy a high quality automatic mobile robot, please leave us a message.

Send product request

Other supplier products

| Forklift AGV | Forklift agvsare divided into handling type, stacking type, forward-moving type and counterweight type. The navigation method of the forklift serie... | |

| Latent Lifting AGV | Automated guided AGV lift carts could realize accurate self-positioning according to dispatched tasks and lift, transport as well as unload automat... | |

| C3-13 Single Conveyor Deck Load AGV | C3-13 single conveyor deck load AGV Trolley adopts an upper floating docking platform to achieve smooth docking with line-side equipment, which is ... | |

| C3-14 Single conveyor deck load AGV | C3-14 single conveyor deck load AGV is a standard single-station single-station roller AGV, which uses the bearing roller platform to automatically... | |

| CASUN Automated Guided Vehicle | As a listed AGV company in NEEQ in China (stock code:834863), CASUN, one of the most professional AMR robot companies, has been focusing on AMR AGV... |

Same products

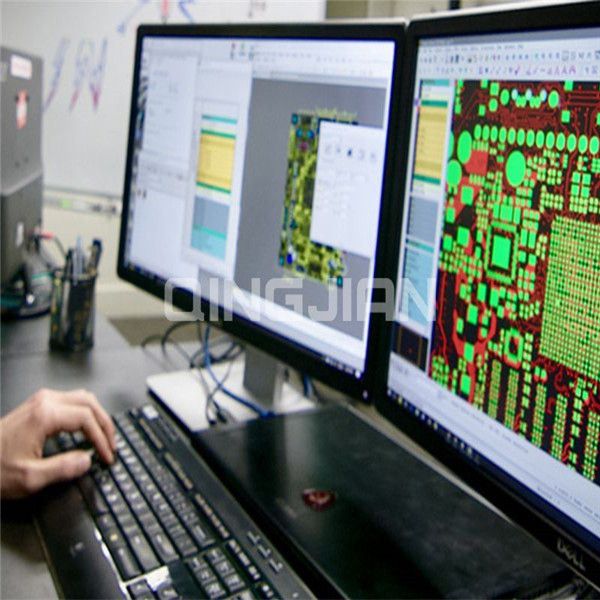

| PCB Assembly Service | Seller: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB Assembly Service Product Description We have 5 SMT (Surface Mount Technology) production li... | |

| PCB design | Seller: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB design Product Description We can provide various types of PCB board designand production, ... | |

| PHILIPS LED Strip HLS288 | Seller: BMT LIGHTING | PHILIPS LED Strip HLS288 Plus 11.5W 4000K 30M IP20 Product date: Model Name:PHILIPS LED StripH... | |

| PHILIPS OEM LED Street Light | Seller: BMT LIGHTING | PHILIPS OEM LED Street Light BMT-BST10D Heat Sink Outdoor Ip65 Waterproof 50w 120w 180w 240w Led ... | |

| PHILIPS Ultinon LED | Seller: BMT LIGHTING | PHILIPS Ultinon LED Headlight bulb S25 12V 5W 11499ULWX2 BA15s Product description PHILIPS Ult... |