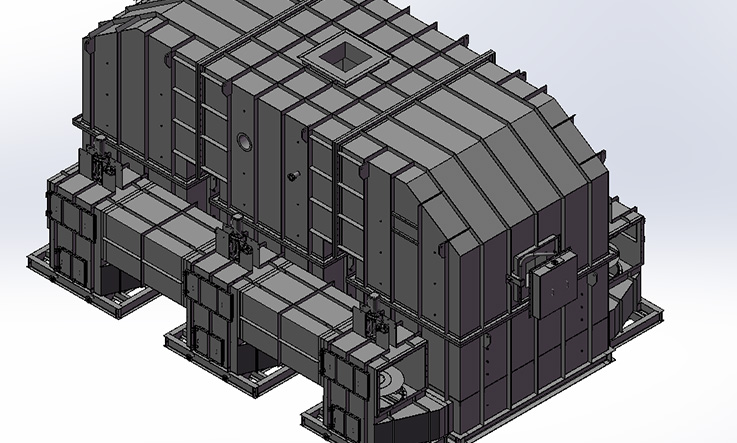

Aluminum Metal Printing Machine

Aluminum plate printing machines are great for achieving full-color, seamless graphics. Metal printing presses such as aluminum can printing machine, beverage can printing machine, tin can printing machine and beer can printing machine are widely used for printing on the surface of the metal packaging industry such as Peel-Off Lid, Dried Food Easy Open End, Canned Food Easy Open End, Beverage Easy Open End, Daily Chemicals Easy Open End, Bottom End, Combo EOE. RUIYUAN main products have covered many application fields such as food (including dry powder), beverage and daily chemical products, etc.

Aluminum Plate Printing Machine Advantages

High Performance

beer can printing machinehave the capability to produce high-quality, full-colour graphics. This means they can print images that cover the entire spectrum of colours, from the lightest hues to the darkest shades.

Energy Saving

Aluminum can printing machines with high automation levels significantly reduce energy costs. They operate at optimal efficiency, minimizing energy waste. Precise control over operation times, with programmed shutdown during inactivity, further conserves energy. Energy-saving features like sleep modes also contribute to lower energy consumption.

Easy Installation

The components of an aluminum can printing machine are highly standardized, ensuring consistent quality and performance. This standardization allows for easy interchangeability of parts, simplifying maintenance and repairs. Additionally, these parts are designed for easy installation, often requiring minimal tools and featuring user-friendly instructions, reducing installation time and potential errors.

How Does An Aluminum Can Printing Machine Work?

An aluminum can printing machine, also known as a can decorator, is a specialized piece of equipment designed to apply ink or other printing materials to aluminum cans. Here is a general overview of how the machine works:

Can feeding: Empty aluminum cans are loaded into the machine's feeding system, which uses a conveyor belt to move the cans into position for printing.

Printing plates: The machine uses metal printing plates that are created from the desired artwork. Each color of the design requires a separate printing plate.

Ink application: Ink is applied to the printing plates using a roller or other application method. The ink adheres to the raised surfaces of the plate and is transferred to the can during the printing process.

Printing: The cans move through the machine, passing under the printing plates in sequence to apply each color of the design. The printing plates press against the can surface, transferring the ink to the can.

Drying: After printing, the cans are dried using drying equipment or infrared radiation to set the ink.

Inspection: The cans are inspected for quality control, including color accuracy, alignment, and any defects.

Packing: The printed cans are then packaged into boxes or onto pallets for shipment.

Overall, the aluminum can printing machine is a sophisticated piece of equipment that requires careful calibration and maintenance to ensure accurate and high-quality printing.

Aluminum Can Printing Process

The aluminum can printing process involves a series of steps to decorate and label aluminum cans with various designs and information. Here is a general overview of the process:

Pre-press: The artwork is prepared and adjusted to fit the size and shape of the can. This includes adjusting color, resolution, and any text or graphics.

Plate-making: The design is transferred onto a metal plate through a photographic process. Each color requires a separate plate.

Printing: The plates are mounted onto a printing press, and ink is applied to each plate. As the can moves through the press, the ink is transferred from the plates to the can.

Drying: After printing, the cans are dried using hot air or infrared radiation to set the ink.

Coating: A protective coating is applied to the cans using metal coating equipment to prevent scratches and scuffs during transportation and handling.

Inspection: The cans are inspected for quality control, including color accuracy, alignment, and any defects.

Packing: The cans are packed into boxes or onto pallets for shipment.

Overall, the aluminum can printing process is a complex and precise procedure that requires careful attention to detail to produce high-quality, visually appealing cans.

RUIYUAN, as one of the mostexcellent offset printing machine manufacturers in china, offers a wide range of colour printing machinefor you to choose from.

Send product request

Other supplier products

| Drying Oven | As one of the professional industrial drying oven manufacturersin China, RUIYUAN continues technological innovation to create the best value for al... | |

| Drying Oven | Drying Oven As one of the professional industrial drying oven manufacturers, RUIYUAN continues technological innovation to create the best value f... | |

| UV Drying Machine | The introduction of the LED UV multi-color system has revolutionized UV curing in the metal printing industry. One LED UV lamp is installed between... | |

| Regenerative Thermal Oxidizer (RTO) | Regenerative Thermal Oxidizer (RTO) produced by RUIYUAN uses ceramic media to recover upwards of 97% of the available energy and is widely consider... | |

| Aluminum Metal Printing Machine | Aluminum plate printing machines are great for achieving full-color, seamless graphics. Metal printing presses such as aluminum can printing machin... |

Same products

| PCB Assembly Service | Seller: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB Assembly Service Product Description We have 5 SMT (Surface Mount Technology) production li... | |

| PCB design | Seller: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB design Product Description We can provide various types of PCB board designand production, ... | |

| PHILIPS LED Strip HLS288 | Seller: BMT LIGHTING | PHILIPS LED Strip HLS288 Plus 11.5W 4000K 30M IP20 Product date: Model Name:PHILIPS LED StripH... | |

| PHILIPS OEM LED Street Light | Seller: BMT LIGHTING | PHILIPS OEM LED Street Light BMT-BST10D Heat Sink Outdoor Ip65 Waterproof 50w 120w 180w 240w Led ... | |

| PHILIPS Ultinon LED | Seller: BMT LIGHTING | PHILIPS Ultinon LED Headlight bulb S25 12V 5W 11499ULWX2 BA15s Product description PHILIPS Ult... |