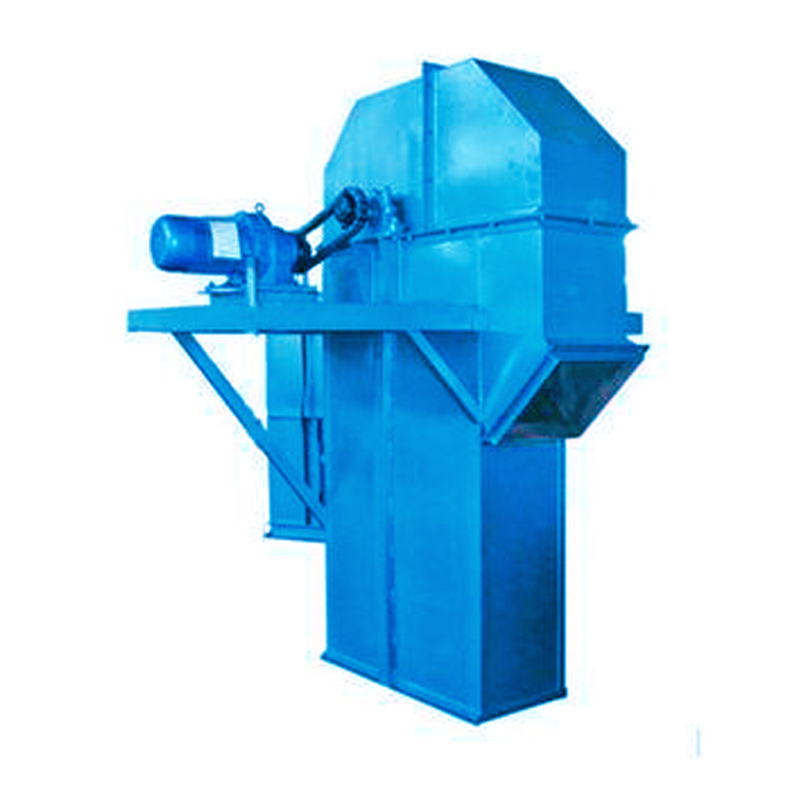

Bucket Elevator

The bucket elevator has the advantages of large conveying volume, high lifting height, stable and reliable operation, and long life. Its main performance and parameters conform to JB3926---85 "Vertical Bucket Elevator" (this standard is equivalent to the international standard. And advanced foreign standards), traction ring chain in line with MT36 --- 80 "high-strength ring chain for mine", the hoist is suitable for conveying powdery, granular and small block-free grinding and grinding properties Small materials, such as coal, cement, stones, sand, clay, ore, etc., because the traction mechanism of the hoist is an endless chain, it allows the delivery of higher temperature materials (material temperature does not exceed 250 °C). The maximum conveying height is up to 40 meters. TG type up to 80 meters.

The bucket elevator is suitable for lifting at a low place to a high place, and the supply material is automatically conveyed and continuously transported after the supply material is input into the hopper through the shaking table. According to the transmission volume, the transmission speed can be adjusted, and the lifting height can be selected as required. The hopper is designed and manufactured by itself. The PP non-toxic hopper makes the bucket elevator more widely used. All sizes are designed and manufactured according to actual needs. The machine, computerized meter design, suitable for food, medicine, chemical industry products, screws, nuts and other products to enhance the feeding, can be used to identify the signal through the packaging machine to control the automatic stop of the machine.

The bucket elevator is a continuous conveying machine that vertically lifts materials by using a series of hoppers that are evenly attached to the endless traction members. Divided into ring chain, plate chain and belt three.

How it works: The hopper picks up the material from the underlying storage and, as the conveyor belt or chain is lifted to the top, it turns around the top wheel and flips downwards. The bucket elevator pours the material into the receiving tank. The drive belt of the bucket elevator with belt drive is generally equipped with a rubber belt, which is installed on the lower or upper drive roller and the upper and lower redirection rollers. Chain-driven bucket elevators are generally equipped with two parallel transmission chains, with a pair of transmission sprocket wheels above or below and a pair of reversing chain wheels below or above. Bucket elevators are generally equipped with an organic shell to prevent dust from flying in the bucket elevator.

Tops elevator buckets: Suitable for lifting at low heights. The supply of materials through the shaking table into the hopper after the automatic operation of the machine to send upward.

The main components of TH Type Bucket Elevator:

The bucket elevator is composed of a shell, a traction element (conveyor chain), a hopper, a driving wheel (head wheel), a steering wheel (tail wheel), a tensioning device, a guiding device, a charging port (inlet port) and a discharge port. (Outlet).

Shallow hopper: The mouth is inclined at an angle of 45° and has a small depth of moist and fluid granular materials.

[Deep hopper: Deep buckets are generally dry and fluid. ]

[Triangle hopper: The material is generally oriented self-flow unloading. ]

Traction member of TH Type Bucket Elevator:

Rubberband: The material is fixed to the taped mouth with screws and elastic spacers, with a width of 35 to 40mm, and the tape transfer temperature does not exceed 60°C. The heat-resistant tape can transport materials up to 150°C.

Chain: The single chain is fixed on the back wall of the hopper; the double chain is connected with both sides of the hopper. The chain hoist adopts single chain when the hopper width is 160-250mm, double-chain when the hopper is 320-630mm, and the main disadvantage is that the wear between the chain links is large and the number of maintenance is increased.

Sprockets: Bucket elevator drive sprocket. The sprocket is used to mesh with an exact pitch block on the pitch chain or cable and is a solid or spoke gear that meshes with the roller chain to transmit motion.

Sprocket tooth design: The sprocket tooth shape must ensure that the chain enters and exits the mesh smoothly and freely, minimizes the impact and contact stress of the link during meshing and is easy to process. The sprocket material should ensure that the gear teeth have sufficient strength and wear resistance, so the tooth surface of the sprocket is generally heat-treated to a certain hardness.

Main features of TH Type Bucket Elevator;

Small driving power, adopts influent feeding, induced discharge, large-capacity hopper-intensive arrangement. When the material is lifted, there is almost no return and excavation phenomenon, so there is little invalid power.

It has a wide range of lifting. This kind of hoist has fewer requirements on the types and characteristics of materials. It can not only improve the general powdery and small granular materials but also can improve the materials with greater abrasiveness. It has good sealing and less environmental pollution.

The operational reliability is good, the advanced design principle and the processing method guarantee the reliability of the whole machine operation, and the time of no failure exceeds 20,000 hours. The lifting height is high. The hoist runs smoothly, so a higher lifting height can be achieved.

The service life is long, the feeding of the hoisting machine adopts the inflow type, there is no need to use the bucket to excavate the material, and the materials are rarely squeezed and collided. The machine is designed to ensure that there is little spillage of materials during feeding and unloading, reducing mechanical wear.

Senotayisa professionalindustrial dust collection systemsmanufacturer. We sincerely invite and welcome people from all around the world to invest and create more values together.

Send product request

Other supplier products

| DMC Pulse Jet Single Bag Dust Collector | Single-pulse bag filter is widely used in mining, electric furnace smelting, machinery manufacturing, chemical products, cement, building materials... | |

| Dust Collector Bags | Dust collector bag replacementis the heart of a bag filter and is generally called a filter dust bag, dust collection bag. The dust collector bag i... | |

| Stainless Steel Screw Conveyor | Screw conveyor stainless steelis divided into two types: horizontal screw conveyor and vertical screw conveyor. This type of screw conveyor system ... | |

| Needle Felt Filter Bags | Positioned in Botou City, a well-known "dust-removing hometown", Hebei Ou Tai Environmental Protection Equipment Co., Ltd.,dust collection system m... | |

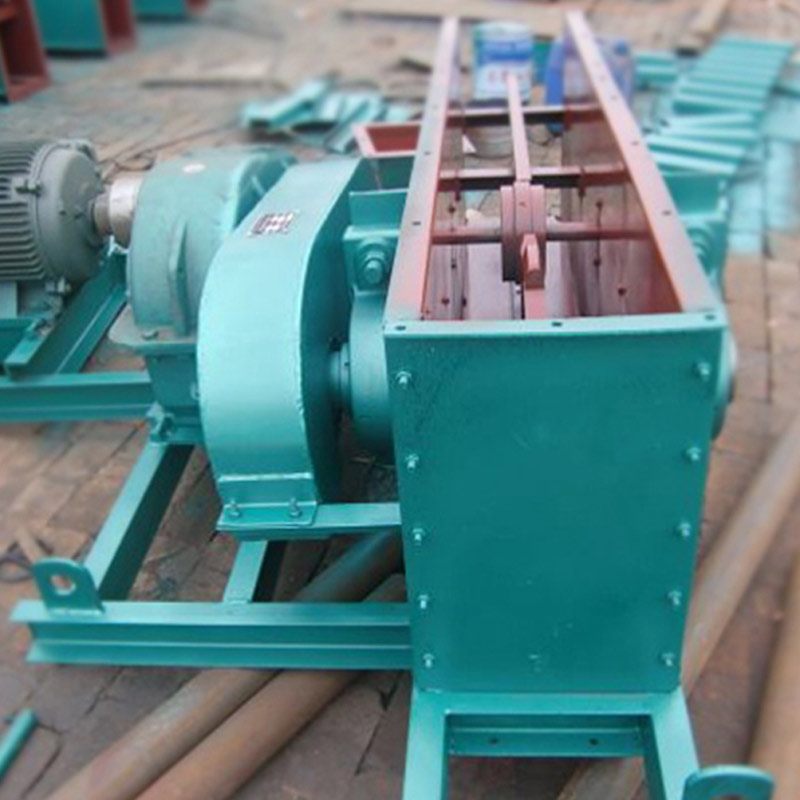

| Scraper Conveyor | With a squeegee chain traction, the conveyor that transports the bulk material in the tank is called a scraper conveyor. KS Scraper Conveyor Scrape... |

Same products

| MTUB43-90511B-12A20 Mini USB Female Connector | Seller: MTCONN ELECTRONICS CO.,LTD | This model is a Mini USB R/A T/H DIP female connectorthat complied with RoHS certificate. It adop... | |

| Radar RD03 | Seller: Xi'an Interwiser Electronic Technology Co., Ltd | The RD03 low-altitude surveillance radaris a Ku-band phased array radar that adopts an all-solid-... | |

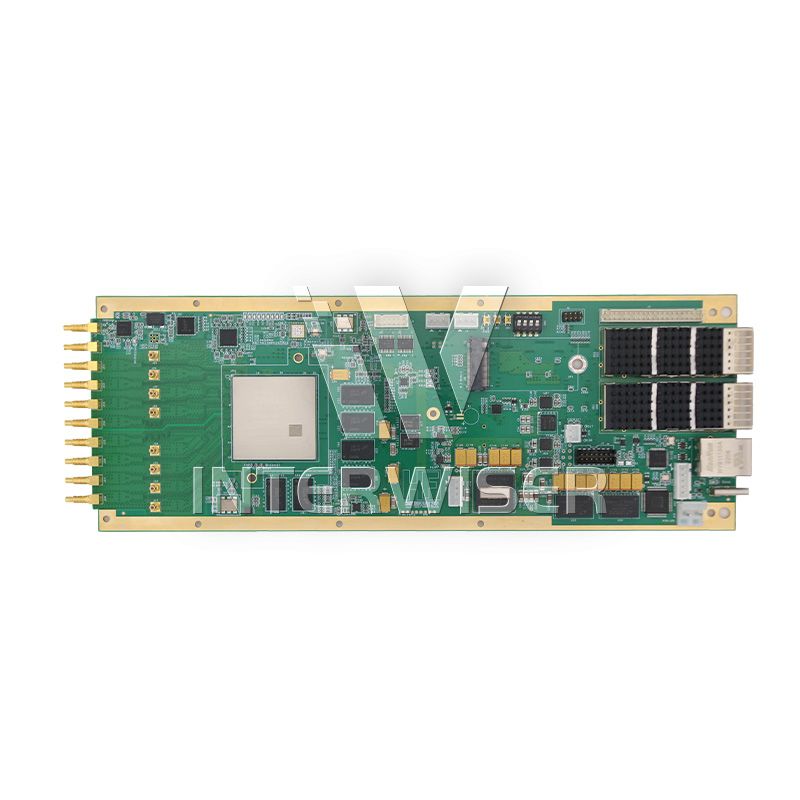

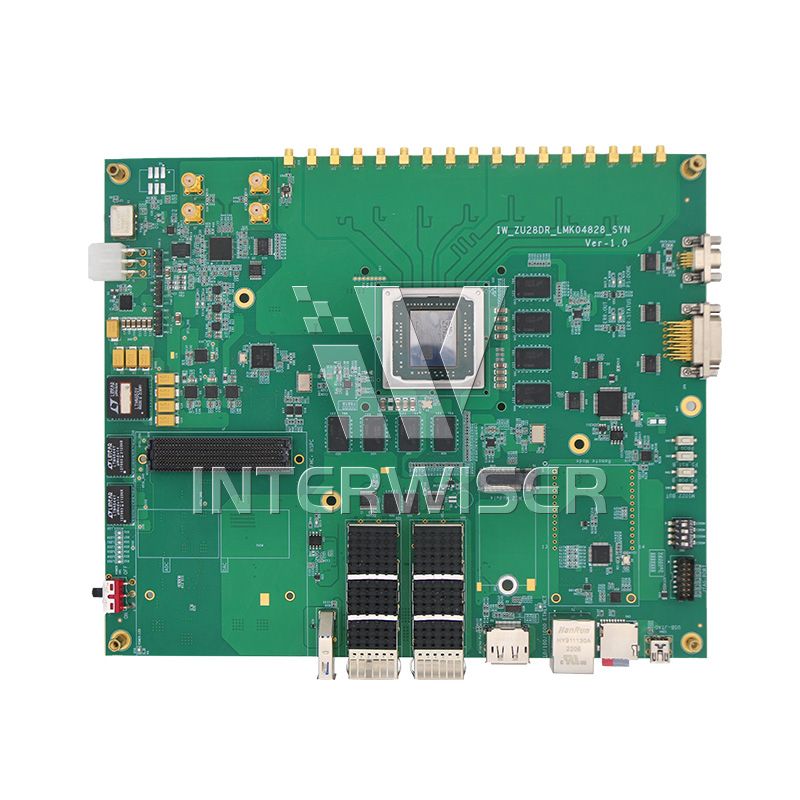

| IWRFSOC8X8 Xilinx RFSoC 3U 4-Channel/ DC-4GHz | Seller: Xi'an Interwiser Electronic Technology Co., Ltd | InterWiser IWRFSOC8x8 3U algorithm evaluation modular systemdesigned for integration into deploye... | |

| IW-RFSOC-48DR-SYN Mixed Signal Processing Card | Seller: Xi'an Interwiser Electronic Technology Co., Ltd | IW-RFSOC-48DR-SYN digital-analog mixed signal processing card, using Xilinx ZYNQ UltraScale + RFS... | |

| all kinds of Analytical Instruments | Seller: O&K GROUP LIMITED | Okwishing supplies all kinds of Analytical Instruments. Okwishing() is a cross-border e-commerc... |