Golden Triangle HDI PCB Capabilities

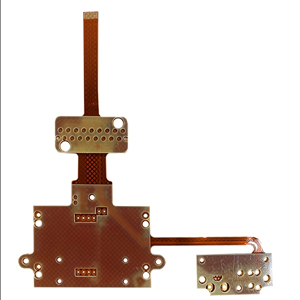

HDI PCBs are constructed using advanced fabrication techniques, and are typically composed of multiple layers of material. These layers are bonded together and etched to form the desired circuit paths. The surface finish of HDI PCBs can also be customized to meet the needs of the application, allowing for improved protection against corrosion and other environmental factors.

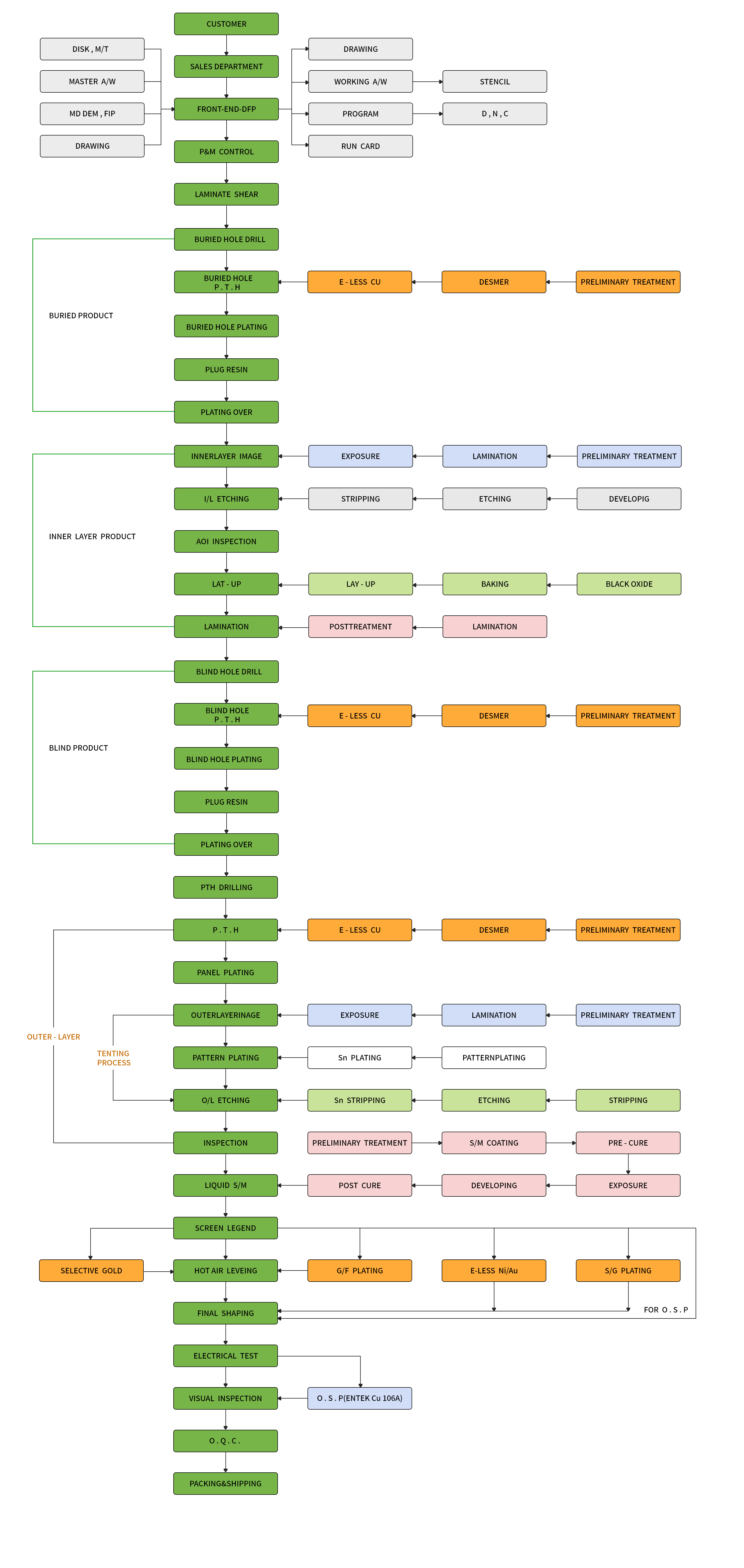

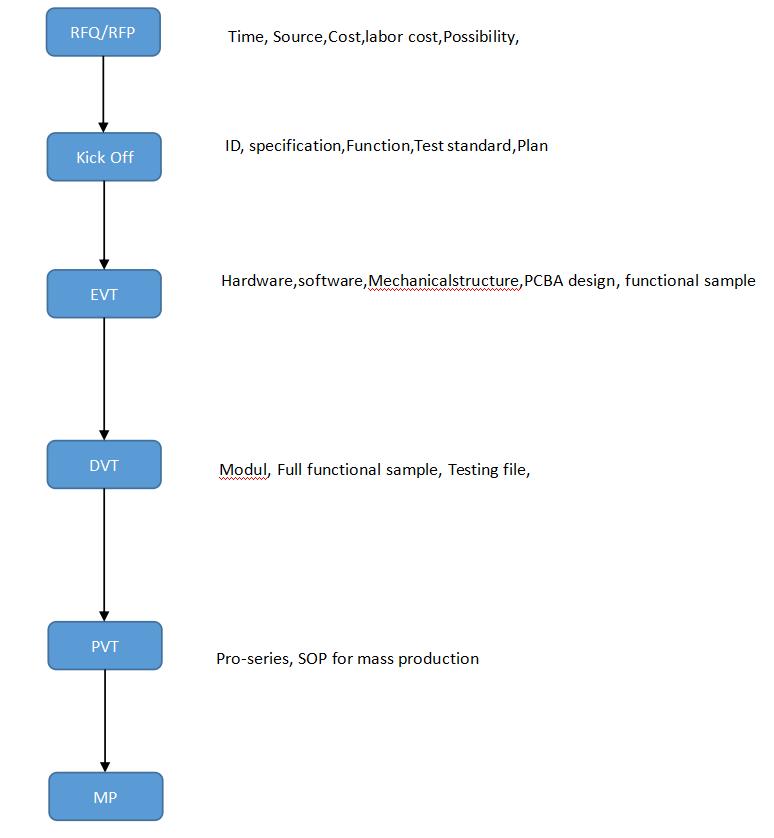

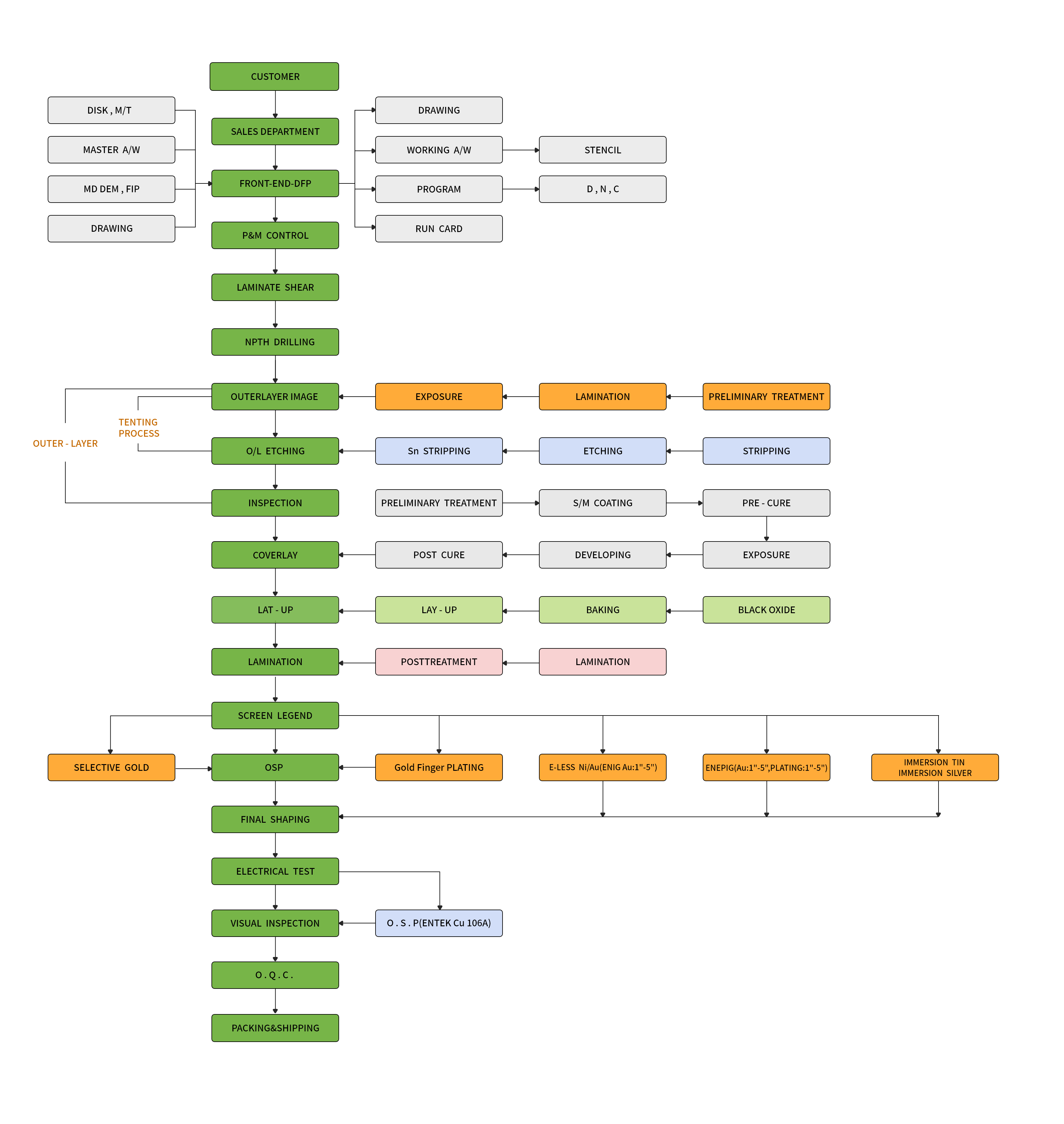

The Process of Manufacturing HDI Board Design

HDI PCB fabricationmanufacturing process involves multiple etching steps to create ultra-thin and ultra-dense circuit boards. It usually uses a combination of laser ablation, chemical etching, and mechanical drilling to create the desired layout. Laser ablation is used to selectively remove copper from the board to create the desired pattern. Chemical etching is then used to create fine routing lines between the components. The mechanical drilling process is then used to create the vias, which are tiny holes that help to connect the layers of the board. Finally, the solder mask is added to protect the board from oxidation and to make it easier to solder components to the board.

Advantages of Our HDI PCB Capabilities

Our HDI PCB capabilities offer many advantages including reduced board size and weight, increased wiring density and shorter trace lengths, increased circuit density and flexibility, improved electrical performance, improved thermal performance, and improved signal integrity. Our HDI PCBs also have higher reliability and improved manufacturability due to the use of finer lines and spaces, improved material processes, and increased trace and via count. In addition, our HDI PCBs are also more cost-effective than traditional PCBs, as they require fewer layers and components, resulting in less material and labor costs. Finally, our HDI PCBs are more environmentally friendly due to the use of recycled materials and reduced energy consumption.

As the best PCB manufacturer, we can offer sorts of printed circuit board for sale, if you are interested, please contact us.

Send product request

Other supplier products

| PCB Design Process | PCB layout process Requirement of DFM All the DFM should apply with the cap For more information about globally sourced components and component ... | |

| 1-Layer Flex PCB Solder Mask Cover Film No Silkscreen | Flex PCB, also known as Flexible Printed Circuit Board, is a type of printed circuit board that is highly flexible in nature. It combines flexible ... | |

| PCBA Components Assembly | PCBA parts Assembly is a process of connecting components to a Printed Circuit Board (PCB) to form a functioning electronic device. It involves sol... | |

| Golden Triangle Flex PCB Capabilities | Flexible printed circuit manufacturing processis a form of Printed Circuit Board (PCB) that is made of flexible, instead of rigid, material. This t... | |

| 2-Layers Rigid PCB Green Soldmask & White Silk Screen | When designing a rigid PCB, it is important to consider the board's size, thickness, and other factors. It is also important to consider the compon... |

Same products

| MTUB43-90511B-12A20 Mini USB Female Connector | Seller: MTCONN ELECTRONICS CO.,LTD | This model is a Mini USB R/A T/H DIP female connectorthat complied with RoHS certificate. It adop... | |

| Radar RD03 | Seller: Xi'an Interwiser Electronic Technology Co., Ltd | The RD03 low-altitude surveillance radaris a Ku-band phased array radar that adopts an all-solid-... | |

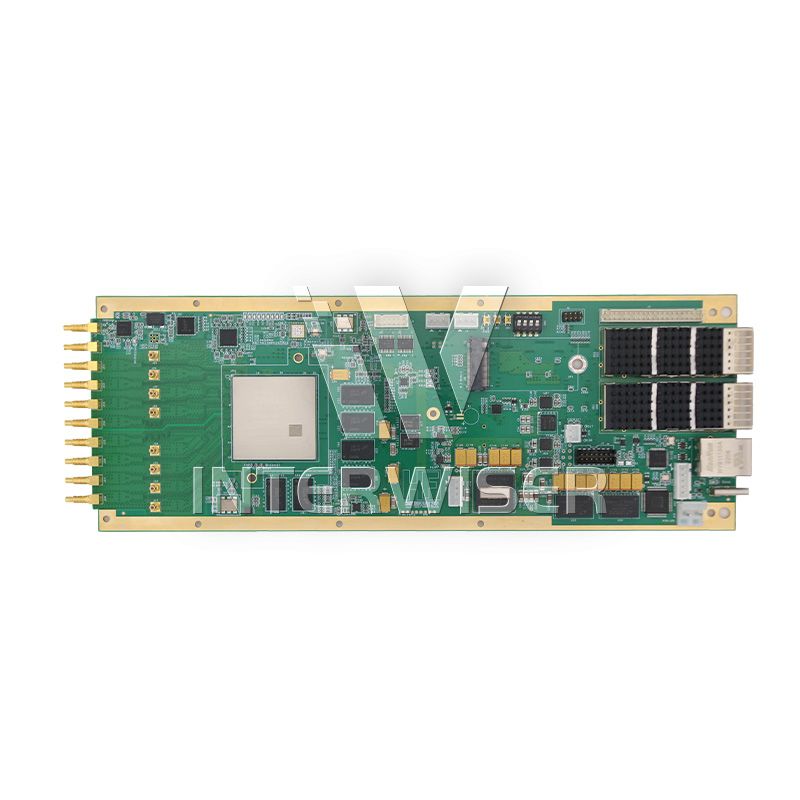

| IWRFSOC8X8 Xilinx RFSoC 3U 4-Channel/ DC-4GHz | Seller: Xi'an Interwiser Electronic Technology Co., Ltd | InterWiser IWRFSOC8x8 3U algorithm evaluation modular systemdesigned for integration into deploye... | |

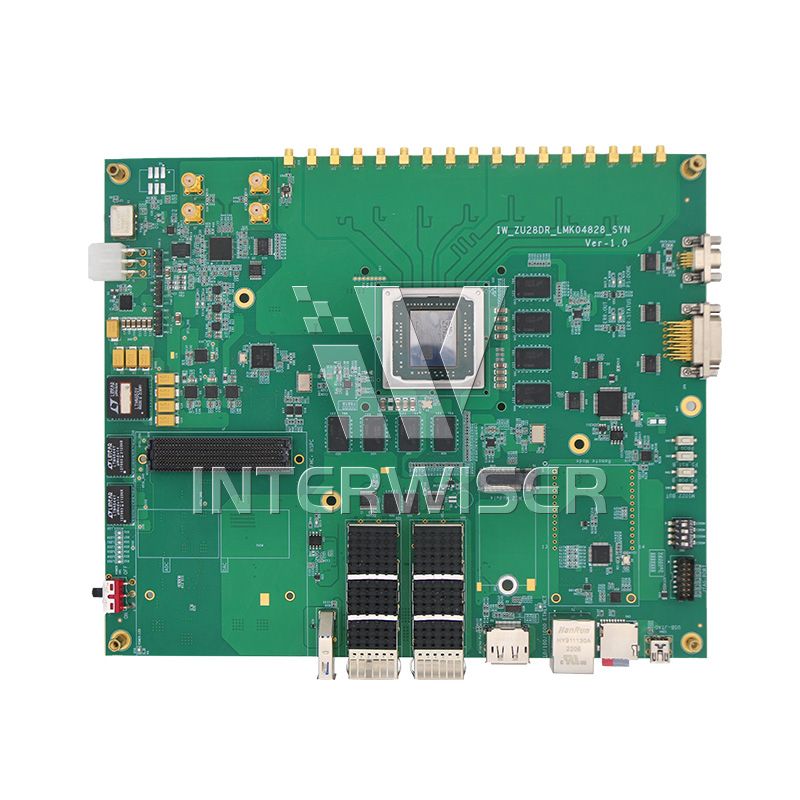

| IW-RFSOC-48DR-SYN Mixed Signal Processing Card | Seller: Xi'an Interwiser Electronic Technology Co., Ltd | IW-RFSOC-48DR-SYN digital-analog mixed signal processing card, using Xilinx ZYNQ UltraScale + RFS... | |

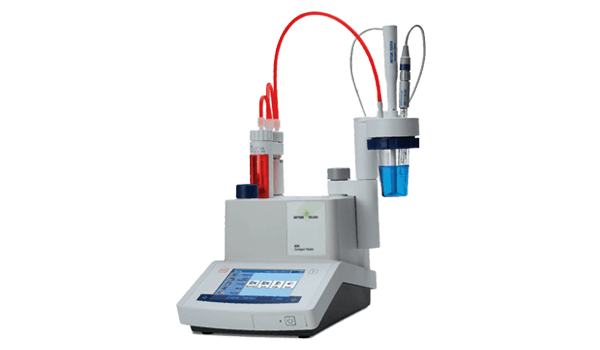

| all kinds of Analytical Instruments | Seller: O&K GROUP LIMITED | Okwishing supplies all kinds of Analytical Instruments. Okwishing() is a cross-border e-commerc... |