METAL BELLOW MECHANICAL SEALS

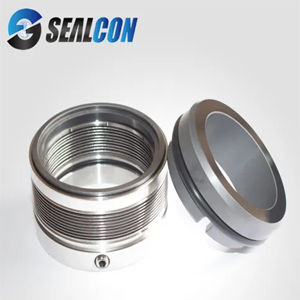

Metal Bellow seals are ideal for high temperature applications and harsh chemical services where elastomers cannot be used effectively. This seal type incorporates metal bellows as a spring-loading mechanism to maintain face contact when the seal is not pressurized and eliminates traditional secondary sealing requirements.

Types of Metal Bellow Mechanical Seal

In applications where the process temperature exceeds elastomer capabilities, metal bellows mechanical seals with graphite secondary seals are a good sealing option. Metal Bellows Single Seal is designed for high-temperature services typically found in chemical and petrochemical processes. Graphite secondary seals replace O-Rings to achieve the higher temperature requirements. Advanced bellows design distributes pressure uniformly across the span of the bellows plate to reduce stress and minimize weld fatigue. Component design replaces most OEM seals.

Materials Combination for Bellows Mechanical Seal

Face: Carbon, SiC, TC

Seat: Ceramic, SiC, TC

O-rings: NBR, EPDM, VITON, Aflas, FEP, Kalrez, Chemraz, Grofoil, etc.

Spring: SS316, hastelloy C, AM350

Metal parts: SS316, hastelloy C

Recommended Applications of Metal Bellow Seals

Process industry

Oil and gas industry

Refining technology

Petrochemical industry

Chemical industry

Hot media

Cold media

Highly viscous media

Pumps

Special rotating equipment

Features of Metal Bellow Mechanical Seal

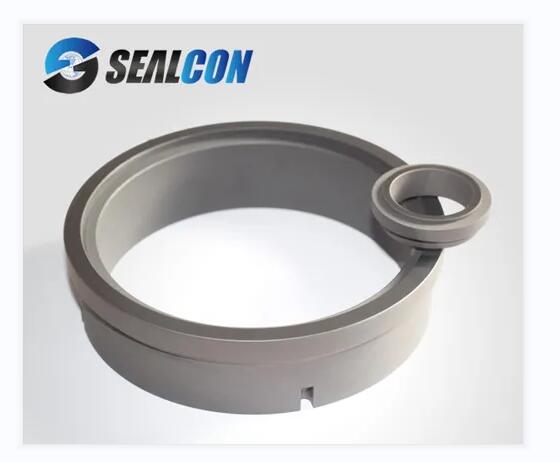

For unstepped shaftsSingle seal, balanced, independent of direction of rotationMetal bellows rotatingAsymmetric bellows form results in even stress distribution with benefits of greater strength and higher rate of flexibilty; seal is bi-rotational and inherently pressure balanced.Smooth profile is resistant to clogging and therefore ideal for slurries and fibrous liquids. Similarly, seal unit is easy to clean and sterilize in place.Unit construction ensures a simple-to-fit seal, with superior heat dissipation paths. Seal unit is reliable and does not wear the shaft.Graphite secondary seals for high-temperature performanceAdvanced bellows design for maximum cycle lifeRotary bellows for enhanced performance in slurry and particulate servicesHydraulically-balanced seal designBlister-resistant carbonProven heat-treated AM 350 bellows constructionGraphite secondary seals for high-temperature performance

Advantages of Metal Bellow Mechanical Seals

For extreme temperature rangesNo dynamically loaded O-RingSelf-cleaning effectShort installation length possiblePumping screw for highly viscous media available (dependent on direction of rotation).For unstepped shaftsSingle seal, balancedIndependent of direction of rotationMetal bellows rotating, rotating bellows, roller bellows

Common malfunction of metal bellow mechanical seals

At high temperature, the bellows are easier to be broken, also the bellows are broken under high pressure (such as the hot water pump).It is easy to occur coking and carbon deposition at the trough between the wave plates, which makes the bellows lose elasticity and cannot compensate, so it can not be used for coking, carbon deposition and crystallized precipitation pump.For external installation mechanical seals, the sealing surface can be pushed open when the pressure in the sealing cavity is more than 0.2MPa. This is because the elastic force of the bellows is small and can not withstand the high pressure of the medium. Therefore, it is not possible to use an external bellows mechanical sealwhen the pressure is high.Because the metal bellow type mechanical seal is a balanced structure, the effective diameter and load factor must be calculated in use. Otherwise, in the high-pressure propane and propane pump, the phenomenon of "spray leakage" is easy to occur.

Difference between Metal Bellow Seal and Ordinary Mechanical Seal

The welded metal bellows mechanical seal has good floating and random compensation, which can compensate for the leakage caused by wear, axial movement and vibration. Welded metal bellows itself as the elastic element and the sealing function, so there is no need to design the general dynamic auxiliary push ring spring type mechanical seal ring, thus avoiding the fine particles due to dynamic auxiliary seal ring caused by the obstruction, dynamic auxiliary seal and high temperature because of its axial friction resistance reduction the seal compensation ability of the problem.

Metal bellows mechanical seal with no auxiliary seal ring, reduce a leak; at the same time reduce the friction resistance compensation mechanism, improve the following; in the petrochemical industry, welding sealing temperature is not restricted by auxiliary seal bellows; for PTFE bellows seal can be used in the corrosive medium. Its drawback is that some bellows have the smaller elastic force and need to add auxiliary springs.

Welded metal bellows are made by interlacing and closely welding each internal and external diameters of each wave plate, so no matter whether they are used as the stationary or rotary type, it is not necessary to consider the problem of rotation. Welded metal bellows can be made from precipitation hardening stainless steel, high-temperature nickel based materials and chrome-nickel corrosion resistant materials. Therefore, welded metal bellows can be applied to a wide range of temperature (-117 C - 426 C), and various acid, alkali and salt media. The selection of different thickness and layers of the wave plate makes it withstand a pressure of up to 7MPa in a special pump. The design of welded metal bellows seal is generally balanced, so its pressure bears little influence on the surface pressure. The welded metal bellows mechanical seal is not only suitable for nonhydrocarbon media, but also for flash hydrocarbon medium. Compared with the ordinary mechanical seal, its service life has been greatly improved, so it has a higher ratio of performance and price.

Sealconis a professionalmetal bellow seal manufacturer, we provide high quality mechanical seal, high temperature mechanical seal, edge welded metal bellows, metal bellow mechanical seal, bellow type mechanical seal, china metal bellowsand etc. For more information, please feel free to contact us!

Send product request

Other supplier products

| MECHANICAL SEALS FOR PUMP | Mechanical seal for pump is a kind of dynamic seal assembly, which is widely used on the rotating shaft. It is also known as the end seal. Consisti... | |

| PTFE Seal | Polytetrafluoroethylene (PTFE), also known as teflon/teflon or plastic king, is a copolymer of tetrafluoroethylene monomer. First, it was developed... | |

| Double Cartridge Mechanical Seals | Cartridge mechanical seal is the rotary ring, stationary ring, spring, auxiliary seal, bushings, glands, Gasket and static seal, total 7 components... | |

| The Processing of Teflon Bellows | Bellows is a corrugated tube shaped elastic part which can be used in the component of the mechanical seal compensation ring, which can be expanded... | |

| MECHANICAL SEALS FOR PUMP | Mechanical seal for pump is a kind of dynamic seal assembly, which is widely used on the rotating shaft. It is also known as the end seal. Consisti... |

Same products

| ARM Linux Kernel 2*A7 128M+256M Nand Flash Edge Gateway | Seller: Shenzhen Beilai Technology Co.,Ltd | The ARMxy BL330 series is a versatile industrial ARM controller designed for flexibleI/O configur... | |

| Rail Cant Measuring Device | Seller: Wuhan Linkage Track Equipment Co., Ltd | ||

| Профилегибочный станок | Seller: Hubei Heavy Industry Equipment Co., LTD | Профилегибочный станокпредставляет собой специальное высокоэффективное технологическое оборудован... | |

| Прессовый станок | Seller: Hubei Heavy Industry Equipment Co., LTD | EZHONG является профессиональным производителем прессов. В настоящее время крупнейший в Китае пре... | |

| Листогибочный станок | Seller: Hubei Heavy Industry Equipment Co., LTD | листогибочный станок с ЧПУ– это ковочное оборудование, используемое для гибки металлическ... |