JZC Waste Oil Refinery Plant Distillation Machine Black Engine Oil Filtration Machine Used Oil Purifier

Company : Chongqing Nakin Electromechanical Co., Ltd Contact Person : Sally liu (Sales Manager) Email: Tel/ 86 Website:

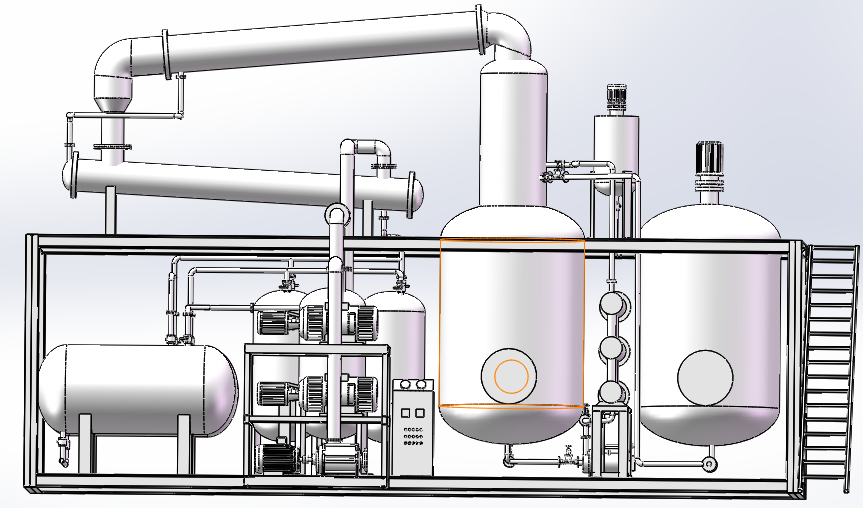

JZC Waste Oil Refinery Plant

Application:

Wasteoilusually collectedfrom machinery, vehicles, shipsetc. which color is black and very dirty.Because the waste oil contains too much contamination, including non-hydrocarbon, alkene, polycyclic aromatic hydrocarbon, metal hydronium, impurities, metal particles, asphaltene and colloid etc.thereby it is harmful for the lubricating system and car engine etc, waste oil lost it’scontrolfriction whichhave to be replaced.

Transitional way to recycling the waste oil is by acid way, which will produces much waste sludge, bad smell, non-friendly environment, and the produced base oil is not purity, and it is easily oxidized. Many countries forbid the acid way.

So our company researches the new waste oil vacuum distilling machine (JZC waste oil distillation machine),it is special for distilling and regenerating the black waste lube oil, including waste engine oil, lube oil, hydraulic oil, gear oil, dirty diesel oil, mixed oils etc.This equipment adopts physicochemical way to polymerize, passivity, absorb, eliminate impurities and harmful contaminations. JZC waste oil distillation machine heat the waste oil to (from 110℃ to 350℃) different temperature under high vacuum condition, making Hydrocarbon molecules break out, and re-order combination, forming diesel oil, lubricating base oil etc. JZC machine is very suitable for the small oil refinery company, also for the small oil company who want to make the oil by self.

◆◆◆◆Advantage:

◆Safety design, during the working process, raw materials oil is always flowing and flashing between the distillation tank and heating system, there is no any coking happen in the pipes and tanks, so the system is 100% safety, and long life time.

◆There are optional ways to heat the oil, like the boiler way by using fuel, natural gas or coal. Also, if machine is small capacity, we can use the electric heating way.

◆By using the high vacuum distilling way, so the distilling temperature is low, energy saving and safety.

◆Using the special chemicals to catalyze the waste oil, which makes sure the final diesel oil, gasoline oil and base oil are good anti-oxidation with good color, there is no bad odor. The final oil can be storage for one year without color change and odor change.

◆Oil cooler system adopts the SS304, which has the good heating exchange function, long life time.

◆Environmental friendly, there is only 5-8% of the oil residual under the distilling kettle, which can be use as the boiler heavy fuel, so there is no pollution.

◆The final oil is high purity; gasoline/diesel oil and lube base oil be loaded in different oil tanks.

◆Machine design life is more than 20 years, long working life time.

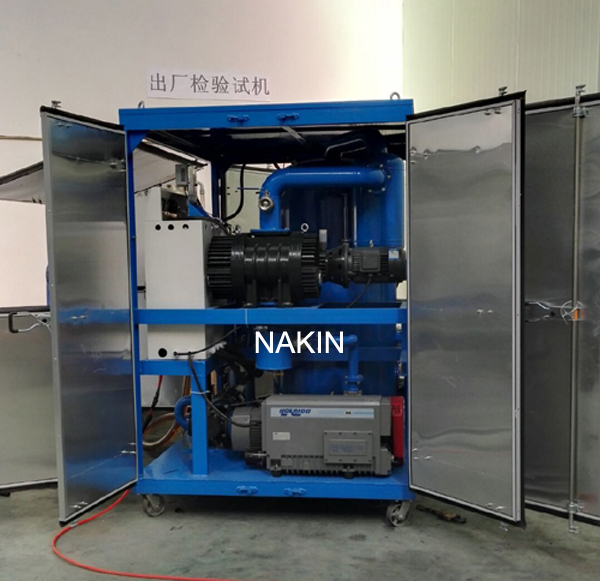

◆Easy operation, only 1 or 2 workers can operate the machine.

Technical Parameter:

|

Index |

Unit |

JZC-2 |

JZC-5 |

JZC -10 |

JZC -20 |

|

Capacity |

Ton / day |

2 |

5 |

10 |

20 |

|

Recovery ratio |

% |

Above 85% |

|||

|

Working pressure |

MPa |

≤0.4 |

|||

|

Working vacuum |

MPa |

-0.08 ~ -0.0998 |

|||

|

Working Temperature |

℃ |

80-350 |

|||

|

Working Noise |

dB (A) |

75 |

|||

|

Power supply |

V |

380v, 50hz, 3Phase (Or According user demand) |

|||

|

Heating way |

Electromagnetic-Heater or boiler ( fuel, natural gas or coal) |

||||

|

Pump Motor Power |

kW |

15 |

25 |

45 |

60 |

|

Working Size |

M2 |

200 |

300 |

500 |

700 |

Recovery rate:

|

Final products |

Ratio Percentages |

Distillation temperature |

Vacuum Value |

|

Water |

2% |

80-110 |

-0.098 |

|

Gasoline and diesel |

8% |

120-210 |

500Pa |

|

Light base oil |

40% |

220℃-290℃ |

300Pa |

|

Heavy base oil (Viscosity ≥SN150 ) |

45% |

300℃-350℃ |

200Pa |

|

Oil Residual |

5% |

||

|

Total |

100% |

Send product request

Other supplier products

| TYA Waste Oil Recycling Plant Lubricant Oil Filtration Machine Used Oil Purifier | Company : Chongqing Nakin Electromechanical Co., Ltd Contact Person : Sally liu (Sales Manager) Email: Tel/ 86 Website: TYALubricating Oil Pur... | |

| JZC Waste Oil Refinery Plant Distillation Machine Black Engine Oil Filtration Machine Used Oil Purifier | Company : Chongqing Nakin Electromechanical Co., Ltd Contact Person : Sally liu (Sales Manager) Email: Tel/ 86 Website: JZC Waste Oil Refiner... | |

| ZYD Waste Oil Recycling Plant Transformer Oil Filtration Machine Used Insulation Oil Purifier | Company : Chongqing Nakin Electromechanical Co., Ltd Contact Person : Sally liu (Sales Manager) Email: Tel/ 86 Website: ZYD Double Stage Va... |

Same products

| 4-Shaft Winder Cast Film Machine | Seller: Wenzhou Chaoshun Machinery Co., Ltd. | The 1500–2100mm PVC Cast Film Machine (4-Shaft Winder) is a robust solution built for indus... | |

| Standard Washer 12/15/20/25kg | Seller: Jiangsu Chuandao Intelligent Equipment Co., Ltd. | Kingstar Series washer extractors equipped with the world’s leading washing technology, Ita... | |

| Daily Necessities Molds | Seller: Zhuozhou Yihua Mould Factory | Daily Plastic Products are the most extensive category of plastic products. Most of the plastic p... | |

| Rebar Coupler Threading Machine | Seller: Xingtai Yushi Machinery Equipment Co., Ltd | Rebar Coupler Threading Machineis an essential tool for processing reinforced bars, commonly used... | |

| VH HIGH-SPEED GANTRY PROCESSING | Seller: Ling Yueyang International Trade (Shenzhen) Co., Ltd | ●Powerful cutting capability combined with high precision and performance makes insert and armori... |