Alloy Precision Spare Parts

Alloy Precision Spare Parts

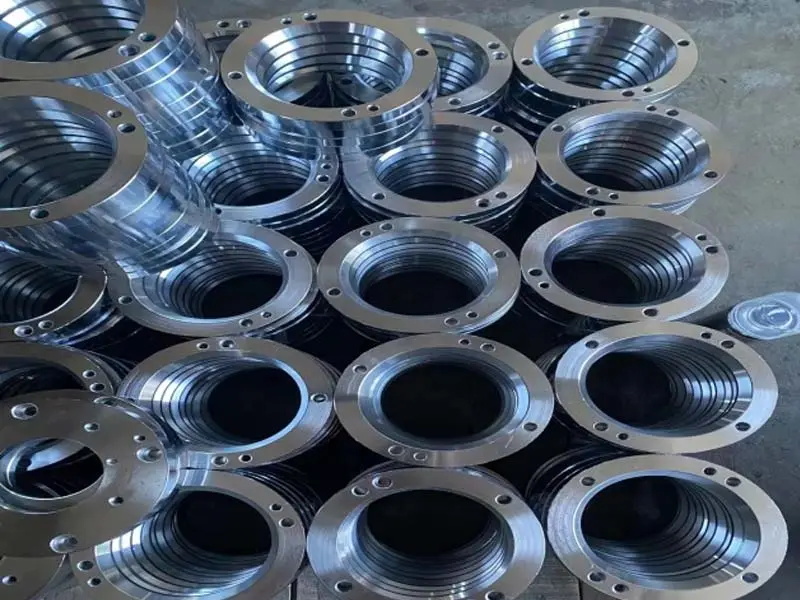

Alloy titanium precision partsare components used to replace worn-out or damaged parts in a machine or apparatus. These parts are made from a variety of materials, including aluminum, stainless steel, brass, and titanium, and are designed to provide a precise fit and function. They may be used to replace broken or worn components in a variety of machines, from industrial and manufacturing equipment to household appliances. Alloy precision spare parts are often less expensive than other types of parts, making them an ideal solution for when replacement parts are needed quickly and affordably.

The Impact of Quality Control on Alloy Precision Spare Parts Manufacturing

Quality control is important for the production of precision spare parts made from alloys. Quality control involves a series of processes to ensure that products meet standards and are safe for use. Quality control helps to guarantee that spare parts are made to the highest standards and are free from defects. Quality control begins with the selection of the correct alloy for use in the production of spare parts. This ensures that the alloy is suitable for the intended application and will meet the required specifications.

Quality control then continues with the production process, including inspection and testing of the spare parts. During this process, any materials that are not up to standard are rejected and not used. Quality control also involves the implementation of measures to ensure that the spare parts are not damaged during production or shipping. This includes the use of protective packaging and the implementation of processes to ensure that the parts are securely stored.

The Benefits of Using Alloy Precision Spare Parts for Machinery Repairs

Alloy precision spare parts for machinery repairs offer many benefits to businesses, including improved efficiency, cost-effectiveness, and enhanced safety. Alloy parts are machined to exact specifications and are designed to fit perfectly into machinery to ensure optimal performance. Alloy parts are also highly resistant to wear and tear, making them an ideal choice for long-term use. Other benefits of using alloy precision parts include:

If you want to know more kinds of titanium cnc machining parts, please visit our website.

As a precision machining manufacturer, we will do our best to meet all the needs of clients.

We are a professional precision machiningmanufacturer focusing on OEM & ODM customized services of precision quality machining. We own a precision machining factory specializing in precision cnc machining, non-standard spare part processing, metal stamping and metal prototyping.

Send product request

Other supplier products

| Electroplating | ElectroplatingServices The custom electroplatingprocess is a method of laying a layer of metal on a conductive body using the principle of electro... | |

| Metal Stamping Parts | Metal Stamping Components Most of the world's steel is made into finished products by stamping. The body, chassis, fuel tank and radiator sheet of... | |

| Custom Precision Machined Parts | As the leading supplier of custom precision parts, we have 10 years of experience in custom fabrication services which include CNC machining servic... | |

| CNC Milling | CNC Milling CNC Milling is the ideal method for rapid prototyping and for batch manufacturing of plastics and metals. As a cnc milling service sup... | |

| Punches and Bushings Parts | Punches and Bushings Parts When punching holes with a concave die, the standard of hole diameter is based on the diameter of the convex die. For ex... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | Seller: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | Seller: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I龙门起重机换轨装置 | Seller: Wuhan Linkage Track Equipment Co., Ltd | ||

| Portable Rail Vertical Tamper | Seller: Wuhan Linkage Track Equipment Co., Ltd | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | Seller: Tangshan Sndou SiC Ceramics CO,Ltd | Riser Tube (stalk ceramic / feeding pipe) as key part of LPDC low pressure die casting machines, ... |