Punches and Bushings Parts

Punches and Bushings Parts

When punching holes with a concave die, the standard of hole diameter is based on the diameter of the convex die. For example, if the hole diameter is ф10mm, the diameter of the punching die is 10mm, and the die clearance is adjusted by the size change of the punching die. 2. The selection of the punching die When punching different materials with the punching die, the different materials of the punching die will affect the selection of the die clearance. In order to ensure the quality of the hole section, dimensional accuracy, and to improve the service life of the punching die and the die, the die clearance is usually selected in consideration of the deviation in the production of the die and the wear and tear in use, and usually, only an appropriate range can be selected as a reasonable clearance.

What is The Role of A Bushing?

The use of bushings is more flexible and it can play a lot of roles. In general, oem bushings are a type of component that protects the equipment. The use of bushings can reduce the wear, vibration and noise of the equipment, and have the effect of corrosion prevention. The use of bushings can also facilitate the maintenance of machinery and equipment, and simplify the structure of equipment and the manufacturing process.

The role played by the custom bushing in the actual work and its application environment and purpose have a lot to do with it. In valve applications, bushings are installed in the valve cover and sleeve of the valve stem to reduce valve leakage and achieve sealing. In bearing applications, bushings are used to reduce wear between the bearing and the shaft seat and to avoid increased clearance between the shaft and the bore.

Why Do Punches Break Easily?

When using stamping dies for production, the phenomenon of punch breakage will occur. The following will introduce you to the common causes of punch breakage.

1. The closing height is too low and the punch is cut into the cutter part too long.

Solution: Adjust the closing height so that the punch cutter is of the right length.

2. Improper positioning of the material causes the punching tungsten steel punch to cut a single side and fracture due to uneven force.

Solution: Adjust the positioning or feeding device.

3. The lower die waste blocks the cutter's mouth, causing the punch to break.

Solution: Re-drill the big drop hole to make the drop material smooth.

4. The fixed part of the punch (clamping plate) and the guiding part (playing plate) are offset.

Solution: Repair or re-linear cut into the block to make the punch head go up and down smoothly.

5. The punching plate is not well oriented, causing the punch to be stressed on one side.

Solution: Repair the gap in the punching plate.

6. The punch cutter is too short, and the punching plate is dry.

Solution: Change the punch again and increase the length of the cutter part.

7. The punch is not fixed well and moves up and down.

Solution: Re-fix the punch so that it cannot move up and down.

We can provide types of center punches for sale, and the center punch price is reasonable, if you have needs to buy center punch kit / center punch, please contact us.

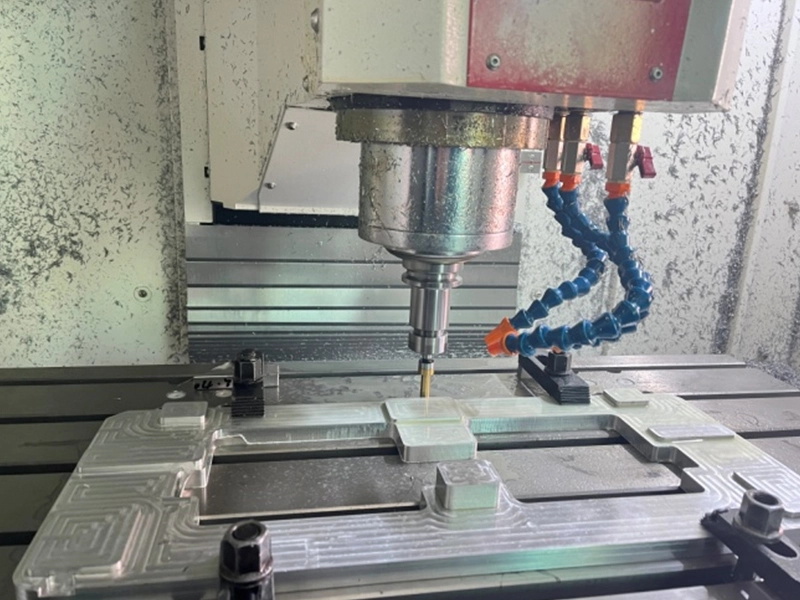

We are a professional precision machining manufacturer focusing on OEM & ODM customized services of precision quality machining. We own a china precision machining factory specializing in precision cnc machining, non-standard spare part processing, metal stamping and metal prototyping.

Other supplier products

|

|

CNC Prototyping |

CNC Prototyping

CNC Milling and CNC Turning are excellent CNC machining prototyping options for parts that require prototypes to be evaluated in t... |

|

|

Metal CNC Machining Parts |

cnc metal parts factory/ cnc machining metal parts factory

custom cnc metal parts/ cnc machined metal parts/ metal cnc machined parts/ metal cnc p... |

|

|

Metal CNC Machining Parts |

Metal CNC Machining Parts Custom cnc metal parts are suitable for hand board production and small batch production, various types of parts in large... |

|

|

CNC Milling |

CNC Milling

CNC Milling is the ideal method for rapid prototyping and for batch manufacturing of plastics and metals. As a cnc milling service sup... |

|

|

Positioning Components |

Keep the following points in mind when positioning components.

One or more components can be added for positioning even when the positioning too... |

All supplier products

Same products