CNC Machining Parts

CNC Machining Parts

OEMparts cnc machiningare components produced by CNC (computer numerical control) machining. CNC machining is a manufacturing process primarily used for producing precision metal and plastic components. The process involves using a computer to control a machine tool, such as a milling machine, lathe, or router, to produce the desired part. Order custom cnc partsare widely used in a variety of industries, including aerospace, automotive, medical, and defense.

How to reduce/save CNC machining costs

Type of material

The size of the material

Type of CNC machine

The complexity of the part geometry

Delivery time frame required for production runs

The difference between rounded and chamfered corners

mechanical engineering drawing and design

Rationalizability of machining processe

CNC Machining Parts of Different Materials

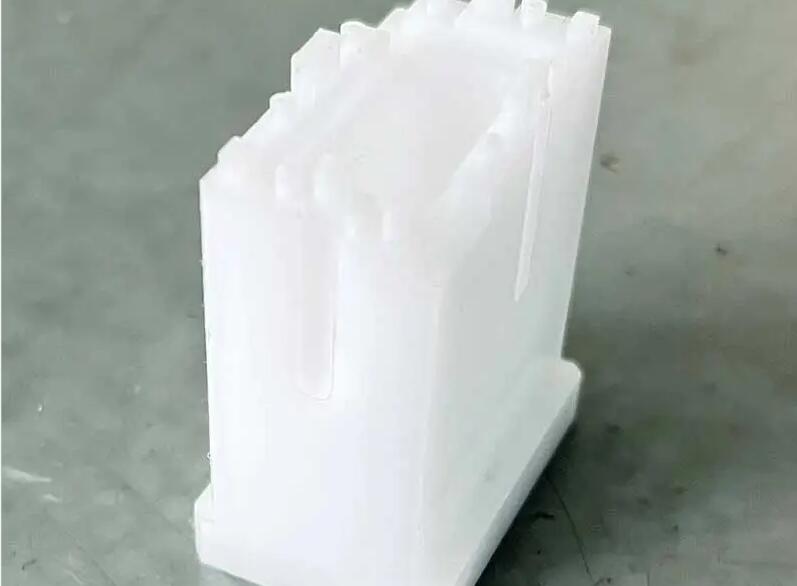

Plastic Custom CNCParts Machining

The advantages of plastic parts are fast prototype turnaround, economical processes, holding tighter tolerances, and greater resistance to corrosion and chemicals. Applications can be found in the medical industry, automotive industry, and electronics industry.

Metal CNC Machining Parts

6061 Anodized Aluminum Light weight, high strength, corrosion resistant, beautiful, easy to dissipate heat, easy to shape, easy to process, easy to conduct electricity, non-magnetic, diversified surface colors.

Specifications of CNC Machining Parts

|

Name |

Description |

|

Max Dimensions |

1600mm x 1200mm x 900mm |

|

Tolerance |

Linear dimension: +/-0.025 mm |

|

Hole diameters (not reamed): +/- 0.025 mm |

|

|

Burrs And Chamfers |

Deburring by default, chamfering according to your requirements |

|

Drawing Format |

2D Drawing: PDF/JPG/DWG |

|

3D Drawing: STP/STEP/IGS/IGES/STL |

|

|

Surface Finishing |

Powder coated, anodizing, bead blasting, black oxide, heat treatment |

What Parts Can You Make by CNC Machining?

CNC machining manufactures custom parts for a variety of applications from rapid prototyping to volume production. Here are some of the most common applications for CNC machined parts:

As a custom cnc machining parts factory, we will do our best to meet all the needs of customers.

Precision etching is a process of creating patterns, shapes, and designs on a variety of materials, usually metals, using an etching process. As a part of machining precision, this process is often used in the manufacture of precision parts, such as integrated circuits, sensors, and other electronic components. In precision etching, the precision machining factorycontrols the chemical reaction used to etch a desired pattern into the material, which is then filled with an etching fluid.

More kinds of high precision china machining services, please visit our website.

Send product request

Other supplier products

| Non-standard Parts | Non-standard Parts Standard parts are parts produced in accordance with national standards (GB), industry standards, or foreign standards, mainly f... | |

| Aluminum Non-standard Parts | Aluminum Non-standard Parts Non-standard precision parts hardware processing is the raw materials (stainless steel, copper, aluminum, iron ......)... | |

| Precision Spare Parts | We manufacture high-precision parts for customers around the world for virtually all advanced technology manufacturing industries, such as communic... | |

| Positioning Components | Keep the following points in mind when positioning components. One or more components can be added for positioning even when the positioning too... | |

| Alloy Precision Spare Parts | Alloy Precision Spare Parts Alloy titanium precision partsare components used to replace worn-out or damaged parts in a machine or apparatus. Thes... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | Seller: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | Seller: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I龙门起重机换轨装置 | Seller: Wuhan Linkage Track Equipment Co., Ltd | ||

| Portable Rail Vertical Tamper | Seller: Wuhan Linkage Track Equipment Co., Ltd | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | Seller: Tangshan Sndou SiC Ceramics CO,Ltd | Riser Tube (stalk ceramic / feeding pipe) as key part of LPDC low pressure die casting machines, ... |