BKNET-0102 Welded Pipe Eddy Current Flaw Detector

Eddy current weld testing is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. At the same time, we need to be clear that the welded pipe is, in general, the steel pipe that we usually say, which is a welded steel pipe.

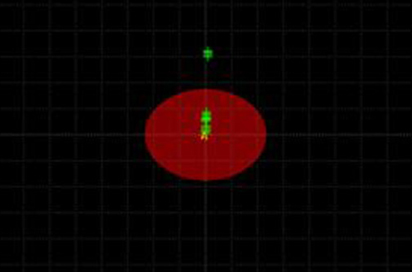

Eddy current weld testing is a non-destructive testing technique for detecting component defects by using the principle that the eddy current induced by the AC electromagnetic coil on the surface of the metal member encounters a defect. The oscillating current is generated in the conductive member by the excitation coil by the principle of electromagnetic induction, and the amount of change in the eddy current is measured by the detecting coil, thereby obtaining information on the component defect.

Eddy current weld testing is a non-destructive testing technique in which an alternating current electromagnetic coil induces eddy currents on the surface of a metal member. Eddy current weld inspection equipment is suitable for the detection of defects in conductive materials, including ferromagnetic and non-ferromagnetic metal materials.

BKNET-01�2 NDT weld testing equipment is used for on-line and off-line eddy current weld inspection of welded pipes. It has high sensitively to axial defects such as unwelded welding, dark spots and open cracks. In the production process, products are caused by welder failure. Slow and long-term injuries can be reliably detected.

BKNET-0102 Eddy Current Testing of Welds Flaw Detector performance

|

Detection channel |

Double channel |

|

Detection speed |

1~500m/min(online) |

|

Frequency range |

100Hz-1MHz |

|

Gain |

0~99dB,step 0.1dB |

|

Phase rotation |

0-360 °step1 ° |

|

High pass |

|

|

Low pass |

1Hz~10000Hz |

BKNET-0102 Weld Flaw Detector Features:

High precision end and end-to-tail signal removal

High precision real-time, delayed alarm output

Fast digital/analog electronic balance

Memory track delay blanking function

Non-equal amplitude phase/amplitude alarm domain

Remote automatic help system

Synchronous alarm output for internal and external clock control

Why BKN NDT Testing Equipment

The technology of BKN originated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a leading high-tech enterprise specializing in developing types of NDT non-destructive testing instruments and equipment in China. The company is committed to the development of eddy current, ultrasonic, magnetic flux leakage and various ndt testing machine, holding independent research and development of a number of national patents.

Send product request

Other supplier products

| Benchtop Magnetic Flux Leakage Testing Equipment | MFI Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to def... | |

| Benchtop Magnetic Flux Leakage Testing Equipment | Benchtop magnetic testing equipment MFI Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test pi... | |

| Bolt Vortex Sort BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Eddy Current Testing for Auto Parts | NDTApplication: Eddy current hardness testingtechnology has been widely used in the detection of metal components in the automotive The eddy cur... | |

| GTET-02 Cylinder Liner Eddy Current Testing Machine | Bokena has eddy current equipment for sale! GTET-02 Cylinder Liner Eddy Current Testing MachineIntroduction Detection method Eddy current testing... |

Same products

| UV Detector | Seller: Xinsheng Pharmaceutical Instrument Co., Ltd | The ultraviolet-visible dual-wavelength detector features high sensitivity and a wide linear rang... | |

| Fabric ici pilling and snagging box | Seller: Standard International Group (HK) Limited | Fabric ici pilling and snagging boxis composed of the same speed motor drive, and to maintain the... | |

| Martindale Abrasion And Pilling Tester | Seller: Standard International Group (HK) Limited | To determine the abrasion and pilling resistance of all kinds of textile structures. Samples are ... | |

| Circular Locus Pilling Tester | Seller: Standard International Group (HK) Limited | Testing Standards: GB/T 4802.1. JIG 040-1990 Product Information: The Circular Locus Pilling... | |

| Bean Bag Snag Tester | Seller: Standard International Group (HK) Limited | Bean Bag Snag Tester, to determine the snagging and picking resistance of knitted and woven fabri... |