Impact Crusher

The Application and Usage of Impact Crusher:

Impact crusher is suitable for materials whose compressive strength is under 350Mpa, and particle size is less than 500mm.

Impact crusher is widely used for sand and rock producing in the industries of roads, railways, reservoir, electricity power and building materials and so on.

The Advantages and Benefits of Impact Rock Crusher:

Technical Parameter of Impact Crusher:

|

Model |

Specification(mm) |

Feedopening(mm) |

TheMaximumFeedingSize(mm) |

Capacity(t/h) |

Power(kw) |

Totalweight(t) |

Overalldimension(L×W×H)(mm) |

|

PF-1007 |

Φ1000×700 |

400×730 |

300 |

30-70 |

4P 37-45 |

12 |

2330×1660×2300 |

|

PF-1010 |

Φ1000×1050 |

400×1080 |

350 |

50-90 |

4P 45-66 |

15 |

2370×1700×2390 |

|

PF-1210 |

Φ1250×1050 |

400×1080 |

350 |

70-130 |

6P 110 |

2680×2160×2800 |

|

|

PF-1214 |

Φ1250×1400 |

400×1430 |

350 |

100-180 |

6P 132 |

2650×2460×2800 |

|

|

PF-1315 |

Φ1320×1500 |

860×1520 |

500 |

130-250 |

6P 200 |

27 |

3180×2720×2620 |

|

PF-1320 |

Φ1300×2000 |

993×2000 |

500 |

165-320 |

6P 250 |

34 |

3220×3100×2620 |

|

PF-1520 |

Φ1500×2000 |

830×2040 |

700 |

300-550 |

4P 315-400 |

3959×3564×3330 |

|

|

PF-1820 |

Φ1800×2000 |

1260×2040 |

800 |

600-800 |

6P 630-710 |

4400×3866×4009 |

The impact crusher is widely used in various kinds of hard and brittle materials such as rock, abrasive, refractory, cement clinker, quartz stone, iron ore, concrete aggregate and others. It is especially suitable for building the architecture with sand or building the road with sand stone. The impact crusher has a simple structure, low price, smooth operation, high efficiency and energy saving. The impeller and the material in the vortex broken chamber greatly reduced the cost of the wear-out parts and the maintenance work. The impact crusher effectively solved the "iron pollution" in the crushing process of glass and other materials. It also solve the "card" problem in the process of the crushing of steel slag. The ingenious internal airflow’s self circulation eliminates the dust dispersion.

The Factors Which Affect The Production Capacity

Generally speaking, there are many factors affecting the production capacity of the impact crusher. All in all, there are 5 factors. As following, the GUIKUANG machinery will describe these 5 factors and put forward the corresponding solutions.

The main problem which many customers are concerned about is the maintenance. GUIKUANG machinery manufacturers pay special attention to this kind of problem in the production of impact crusher. The impact crusher designed by us is mainly composed of the feeding port, the feeder, the overflow, the impeller, the crushing chamber, the counter attack board, the spindle, the frame, the motor and so on. It has the characteristics of reasonable structure and stable operation. If there is a failure in the operation, the customer can open the observation door to view the internal condition of the equipment and adjust the equipment parts. The technical personnel of our company will teach the customer the basic operation and maintenance skills.If there is a problem that you can't solve, welcome to call our company's after sale tele. Because our factory equipment is lifelong warranty, we are very glad to serve you.

The operational principles of impact crusher

The materials are entered into an impact crusher by the feed hopper, and then they will be divided into two parts by the feeder. One part is entered into a high-speed rotating impeller from the middle of the feeder. The acceleration speed in the impeller can reach hundreds of times the acceleration of gravity, and then it is ejected from the three uniform flow passages at 60-70 meters per second. Firstly, a part of the material that falls from the feeder will be hit and broken, and then it impact on the material lining layer of the vortex branch together, bouncing off the material liner, impacting to the top slant of the vortex cavity, and changing its direction of motion, deflecting downward movement, and forming a continuous material curtain from impeller channel. Such a material is subjected to two or even multiple probability impact, attrition, grinding and crushing in the whirling cavity. The broken material is discharged from the lower discharge gate. The closed loop system is formed with the circular screening system and it. Generally, the material can be broken into 20 parts in three times cycles. During the whole process of crushing, the materials impact and break with each other. They won’t directly contact with the metal element. However, they will impact, rub and break with the material liner, which will reduce the pollution and prolong the wear time of the machine. The vortex flow the whirling chamber eliminates the dust pollution. The ingenious internal airflow’s self circulation inside the vortex flow eliminates the dust dispersion.

If you want to buy impact mill rock crusher,contact us now.

Send product request

Other supplier products

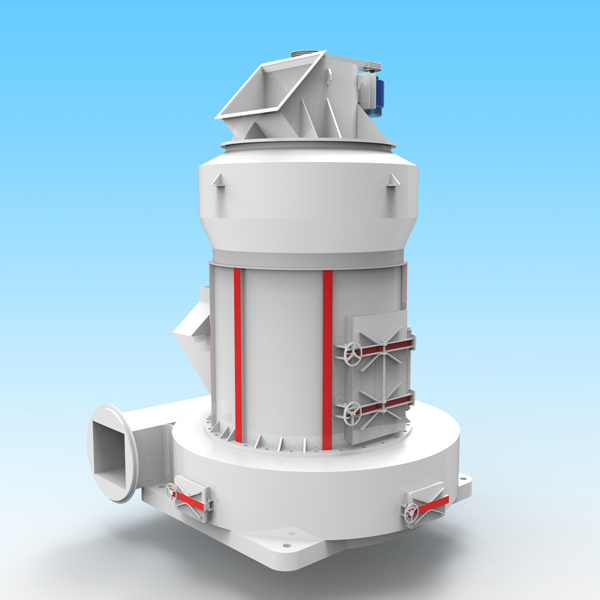

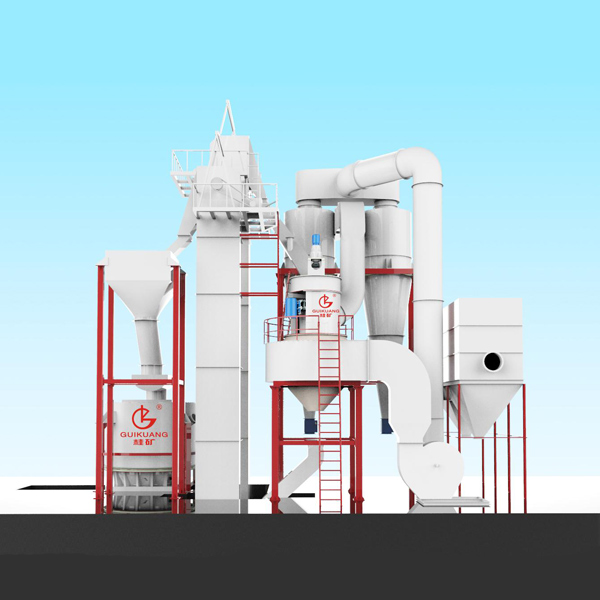

| Raymond Mill | Raymond Mill As national powder R&D center, GUIKUANG has made much efforts and contributions for the development of powder industry more than 4... | |

| GK1720A Pendulum Grinding Mill | GK1720A Grinding Mill is designed by our technicians based on GK1720 mill.This is a large type mill with optimized design. Technical & Structu... | |

| GK-PSH Type Water Spray Dedusting Lime Slaker | GK-PSH Type Water Spray Dedusting Lime Slaker Model: A type C typeE type based on different lime slaker capacity GK-PSH Type Water Spray Dedusting... | |

| GKW970 Micro Powder Mill | GKW970 Micro Powder Mill is a new modified superfine powder mill developed by our R&D team for grinding 400-1250 mesh powder based on client&rs... | |

| Ultrafine Mill | GKH1032D Ultrafine Ring Roller Millis a developed kind of grinding mill with optimized design & structure. It is mainly used in deep processing... |

Same products

| Metal Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Metal Insulated Composite Panel Systems The system is composed of fire-resistant composite metal... | |

| AluzincMg-Al-Zn Alloy Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | AluzincMg-Al-Zn Alloy Composite Panel Systems Introducing magnesium aluminum zinc composite pane... | |

| Aluminium Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Aluminium Insulated Composite Panel Systems This system features composite panels manufactured i... | |

| 3D Aluminium Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | 3D Aluminium Composite Panel Systems The 3D Aluminium Composite Panelutilizes aluminum alloy she... | |

| Calcium Silicate Board Integrated Exterior Wall Insulation | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Calcium Silicate Board Integrated Exterior Wall Insulation and Decoration Panel Leboomoffers hig... |