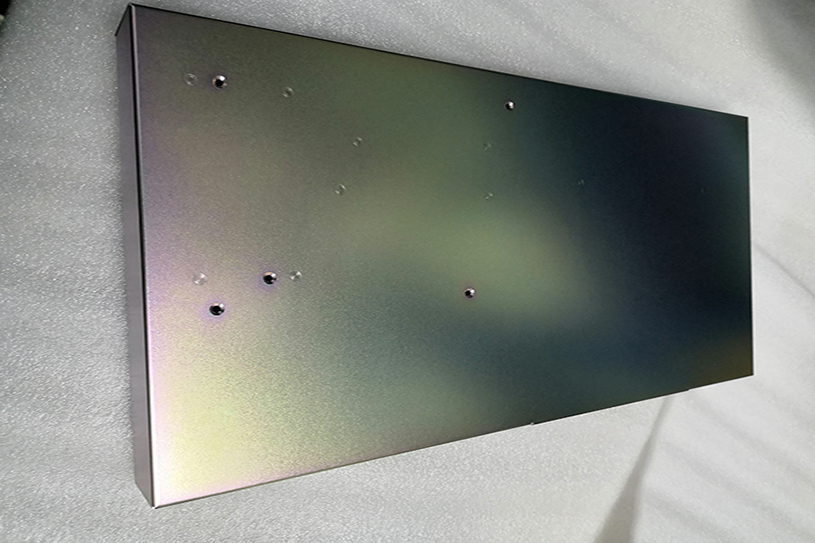

Custom Laser Welded Parts

Custom Laser Welded Parts

Material:

Stainless Steel/Aluminum/Iron/SECC

Thickness:

Surface treatment:

Spray and powder coating

Process:

Blanking - hydraulic forming logo- bending - riveting - internal laser welding - screen printing.

Benefits of Custom Laser WeldingWork

save metal materials and reduce structural weight;

Simplify processing and installation to improve production efficiency;

High structural strength and good sealing of joints; To provide greater flexibility for structural design;

The main technique used for the custom laser welded parts is laser welding fabrication.

The laser welding brassprocess is heat conduction, that is, the laser radiation heating workpiece surface, surface heat through the heat conduction to internal diffusion, through the control of laser pulse width, energy, peak power, and repeat frequency and other parameters, the workpiece melting, forming a specific pool. Due to its unique advantages, it has been successfully applied in the precision welding metal parts.

About the blank, We also have laser cutting and fabrication services for this product. Our sheet metal laser cutting service is also very mature. The cut hole has very few burrs. Moreover, laser cutting features high precision and fast production speed.

we are a professional stainless steel fabrication factorywith an experienced engineering making custom products according to clients' sheet metal welding drawing. We accept CAD and 3D(IGS, STP, DWG) format.

Packaging of Laser Welding Work

Suitable to sea transport.

Plastic film & kraft paper packing

Plastic bag packing

Plywood board packing

Wood box packing

Pallet packing

Bundle packing

As per customer's requirement

One-stop service from raw material supply, sheet metal profiling, steel structure fabrication, surface treatment, warehousing to logistics;

As one of reliable sheet metal fabrication companies, we are very accurate in both big hole and a small hole, and we are very confident in our technology and products. We provide custom laser welding for you, such as laser welding steel, laser welding copper, and laser welding sheet metal.

If you are interested in our technology or need our technical support, please feel free to leave a message or contact us via We will reply as soon as possible.

Send product request

Other supplier products

| Stamping Computer Enclosures | Surface treatment: in the photo we not show the surface treatment but we could offer the powder coating and anodizing and silk print and color pla... | |

| Sheet Metal Bending | Sheet metal bending is a process in which a metal sheet is passed through a pressure device and a special mold to transform a flat sheet into a thr... | |

| High Precision CNC Parts | As a professsional stainless steel fabrication factory, Shenzhen HSJ Metal Fabrication Co., Ltd. has rich experience in providing professional shee... | |

| Electroplated & Anodized Enclosure | Detail Surface treatment : anodized(Zinc/Nickel/Chrome/Plated, Spray paint, powder costing etc.) Material: sus/spcc/secc Tolerance:0.1mm Engrave... | |

| Aluminum & Anodizing Enclosures | Aluminum & Anodizing Enclosures Material: Aluminum plate, sus , secc ,sgcc ,spcc etc. Thickness: Process: Blanking - hydraulic molding... |

Same products

| Metal Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Metal Insulated Composite Panel Systems The system is composed of fire-resistant composite metal... | |

| AluzincMg-Al-Zn Alloy Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | AluzincMg-Al-Zn Alloy Composite Panel Systems Introducing magnesium aluminum zinc composite pane... | |

| Aluminium Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Aluminium Insulated Composite Panel Systems This system features composite panels manufactured i... | |

| 3D Aluminium Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | 3D Aluminium Composite Panel Systems The 3D Aluminium Composite Panelutilizes aluminum alloy she... | |

| Calcium Silicate Board Integrated Exterior Wall Insulation | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Calcium Silicate Board Integrated Exterior Wall Insulation and Decoration Panel Leboomoffers hig... |