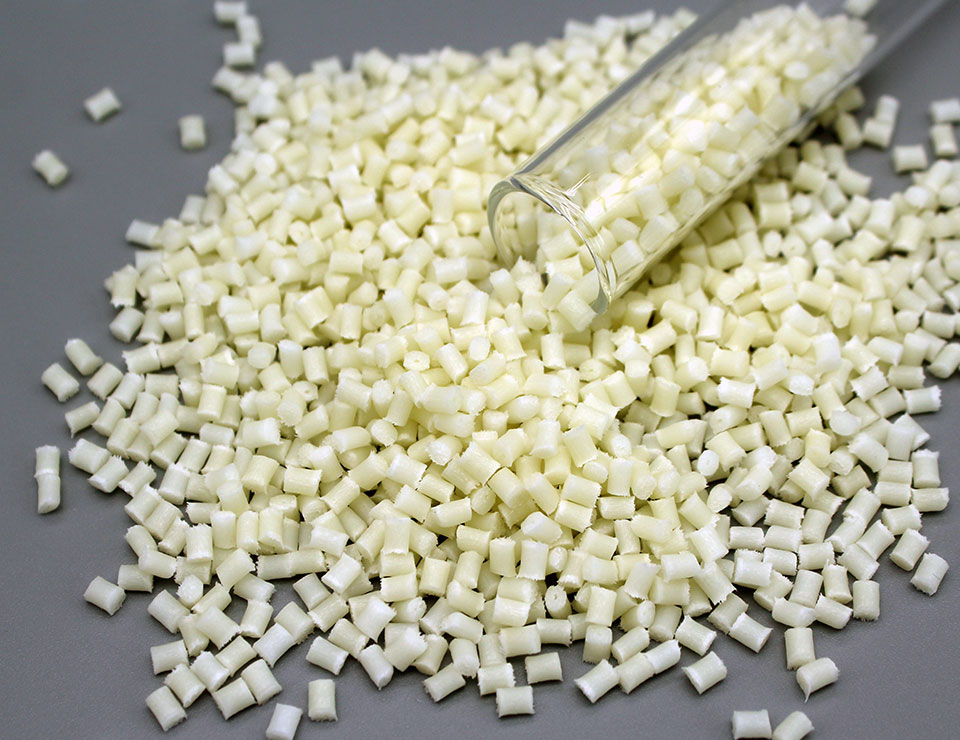

PA66 GF45 (A2011I)

PA66 GF45is a 45% glass fiber reinforced polyamide 6.6 with high stiffness and strength.

Typical Application of PA66 GF45(A2011I)

PA66 45%GF HB grade is applied to the gear field, it requires high strength, high toughness and dynamic balance and applied to the field of sports equipment and electrical tools, it requires high toughness, low temperature resistance, and low cost. Commonly used as mechanical housing.

Processing Detail of PA66 GF45 (A2011I)

Other Details of PA66 GF45 (A2011I)

Physical Property

|

Ash |

(45.0% 1 ISO3451/1) |

|

Conditioned |

600°C*2h |

|

Density |

(1495Kg/m3 1 ISO1183) |

|

Conditioned |

23°C |

|

Shrinkage Parallel Flow |

(0.1-0.3% 1 ISO294-4) |

|

Shrinkage Vertical Flow |

(0.4-0.6% I ISO294-4) |

Mechanical Properties

|

Tensile strength (204.0MPa 1 ISO527) Conditioned |

5mm/ min |

|

Tensile Strain at Break (2.8% I ISO527) Conditioned |

5mm/min |

|

Notched Impact Strength (16.5 KJ/m2 IISO179) Conditioned |

|

|

Flexural Strength (332MPa 1ISO178) Conditioned |

2mm/min |

|

Flexural Modulus (13547 MPa I ISO178) Conditioned |

2mm/min |

Thermal Property

|

Melting Point |

(260°C I ISO11357) |

|

Hot Deformation Temperature |

(258*C I ISO75) |

|

Conditioned |

|

|

Flammability Class |

(HB 1UL94) |

|

Conditioned |

mm |

Injection Molding Conditions

|

Drying Temperature |

130°C |

|

Drying Time |

3h |

|

Cylinder Temperature |

290-310°C |

|

Nozzle Temperature |

290-310*C |

|

Tooling Temperature |

80-100*C |

* Molding conditions arejustfor reference, please make an adjustment based on the actual situation!

As a professional engineering plastic company, Anmei provide pa material, pa4 6 gf30, heat stabilized nylon and etc. Want to know more? Contact us.

Send product request

Other supplier products

| Engineering Plastic Application for Different Industries | Engineering Plastic Applicationfor Different Industries Anmei, one of the most experienced engineering plastic andmasterbatch producers, offers ... | |

| Anmei-PA66 GF for Engineering Plastics | Anmei focuses on the production of modified engineering plastics. We have polyamide pa66modified products with properties of heat-resistant, rei... | |

| PA6 GF30 Heat Stabilized (A1006F, A1016F) for Engineering Plastics | AnmeiA1006F is a kind of material PA6 GF30, which is the injection grade resin by mixing the 30% glass fiber and heat stabilized polyamide 6. Typi... | |

| ABS Chemical Resistance | Compared with general-purpose ABS, ABS plastic chemical resistance is requiring excellent impact performance, rigidity and flow properties. It is o... | |

| PA6 GF in Anmei | As anengineered plastics company, Anmei focuses on the production of modified engineering plastics, among which high-performance nylon 6 engineerin... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |