Injection Mold & Molding Parts Solution

Green Vitality Industry is a full-service mold manufacturer specializing in plastic injection mold design & engineering support, injection mold manufacturing, and qualifying of plastic injection molds. Green Vitality operates plastic injection molding machines ranging from 80T to 400T, 600T, and larger tonnage injection molding machines are in preparation. Our company uses the latest plastic injection molding technology and equipment to provide customers with world-class products and services. Green Vitality Industry provides a wide range of product solutions for the

manufacture of various plastic injection parts.

Application of Plastic Injection Molding

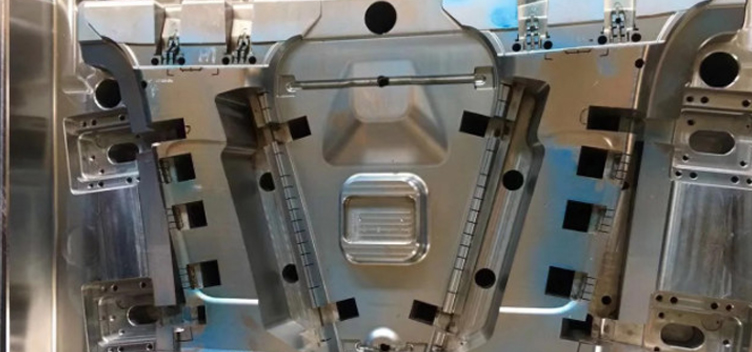

Auto Part Mold

Car Seat Mould for Kids

Auto Rear View Mirror Housing Mold

Car Light Mould

Automotive Air Grille Mold

Auto Bumper Mould

CUSTOM PLASTIC INJECTION MOLD

Electronics Mold

Keyboard Mould

Mouse Mold

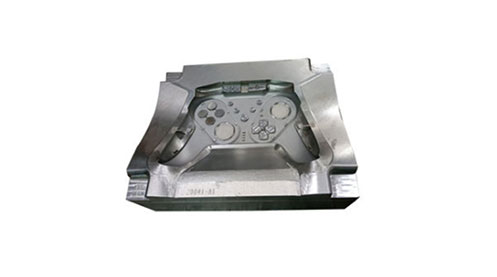

Game Controller Mold

Plastic Enclosure Mold For Electronic Device

Set Top Box Plastic Injection Mold

CUSTOM PLASTIC INJECTION MOLD

Industrial Mold Plastic Injection

Filter and Flow Limiting Apparatus

PVC Pipe Fitting Mould

Plastic Gear Mold

Plastic Connector Mould with Brass Molding Inserts

Home Appliance Mould

LCD TV Mould

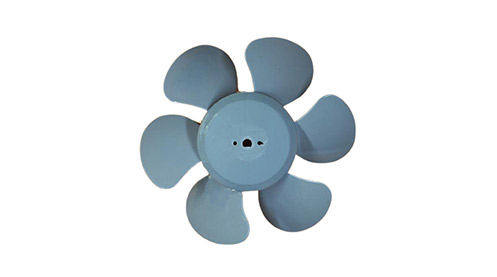

Fan Mold

Refrigerator Drawer Mold

Daily Plastic Injection Mold

Plastic Food Container Mould

Plastic Spoon Mould

Plastic Toilet Seat Mold

Soap Box Mold

Medical Plastic Injection Mold

Medical Test Tube Mold

Teeth Tray Mold

Bicuspids Crown Mold

Thermoset Molding & Aluminum Die Casting

Aluminum Die Casting Mold

Thermoset Molding

Aluminum Die Casting-Holder

CUSTOM PLASTIC INJECTION MOLD

Different Types of Molding Process We Can Provide for You

Single & Multi Cavity Mould

Hot Runner Mould

Double Shot Mould

Over-molding Mould

Insert Mould

Unscrewing Mould

Gas Assisted Mould

Precision Mould

Why Choose Green Vitality Industry

Green Vitality Industryis a long-standing mold manufacturer with ISO9001 Certificated & over 25 years of export molds experience. We use advanced processing and manufacturing technology to produce high-performance injection molds. The combination of process and technology enables us to complete the perfect manufacturing of the mold in the shortest time.

If you want to know more about plastic injection molding price, please contact us.

Send product request

Other supplier products

| Fan Mold | If the weight of each fan blade is not balanced, large vibration, high noise, and large wear of the rotating shaft will occur during high-speed rot... | |

| Game Controller Mold | To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time wil... | |

| Auto Bumper Mould | Auto Bumper Mould The front and rear bumpers of the car are made of plastic, which not only maintains the protection function, but also has the ch... | |

| Industrial Plastic Injection Mold | The injection moldingpart is replacing metal products in many fields of industrial applications to meet the requirement of lightweight industrial e... | |

| Home Appliance Mould | GV Mold has rich experience in home appliance molds (such as television, refrigerators, fans, washing machines, air conditioners, and various smart... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |