Auto Bumper Mould

Auto Bumper Mould

The front and rear bumpers of the car are made of plastic, which not only maintains the protection function, but also has the characteristics of harmony and unity with the body shape, lightweight, and low fuel consumption. The plastic front moulding bumperconsists of three parts, namely the outer panel, the buffer material, and the cross member. The raw materials of the outer plate and the buffer material are all plastic, the beam is stamped into a U-shaped groove from a cold-rolled sheet, and the thickness of the cold-rolled sheet is about 1.5 mm. There are generally two types of materials used in bumper mold: polyester and polypropylene, and the molding process is generally injection moulding.

Bumper Molding for Cars

Green Vitality is a professional automobile mold manufacturer and has rich experience in automobile bumper mold manufacturing.

The Auto Bumper Mold designed by Green Vitality not only has the ability to reduce the injury of drivers and passengers during high-speed impact but also has the ability to protect pedestrians. Green Vitality uses an internal parting structure design for the bumper mold. Compared with the traditional outer parting structure design, the inner parting design has higher requirements on the strength of the mold. Correspondingly, the design concept of the bumper mold made by the internal parting structure is more advanced.

Basic Information for Auto Bumper Mould

Auto Bumper Mould Specification

|

Description |

Auto Bumper Mold |

|

Plastic material |

PP |

|

Mould cavity&core steel |

P20,2738,718H,738H,NAK80,SKD61,E420,etc. |

|

Mould weight (T) |

10T |

|

Feeding System |

Cold runner/ Hot runner |

|

Hot runner brand |

YUDO, HUSKYFISA, HASCO, MOLD-MASTER |

|

Nos of Cavity |

1*1 |

|

Manufacture time (day) |

120 days |

|

Mould life |

≥500000 |

|

Packing |

Vacuum+plywood wooden box |

Green Vitality Can Offer You with Auto Bumper Mould

Analysis: Through the analysis of material properties and product feasibility, such as wall thickness, deformation, plastic feeding position, etc., potential problems can be predicted in advance.

Communication: Maintain close communication with customers, and understand the functional requirements and precautions of products from the perspective of customers, such as requirements for weld lines, requirements for appearance, etc.

Design: Strict design review system and checklist check. Before design, during the design of the scheme structure discussion meeting, the designer will check himself according to the checklist; after design, review together with the manufacturing department.

Quality inspection: Quality inspection of each link to discover mass production problems in advance.

Project management: Each project is equipped with a project manager, who strictly follows the schedule to control the project cycle, and provides weekly progress reports and mold photos for each project so that customers can keep abreast of the status.

Service: From mold design to continuous mass production of products, we provide full life cycle service support.

After-sales service: continuous after-sales follow-up service, proactively providing mass production and processing technical consulting services.

Technical support: In the mass production process, if there is any problem with the mold, technical support will be provided unconditionally.

As a plastic injection factory, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Teeth Tray Mold | A dental impression is a mold removed from a tooth to diagnose and treat dental conditions. They are also used in forensic science. Impressions are... | |

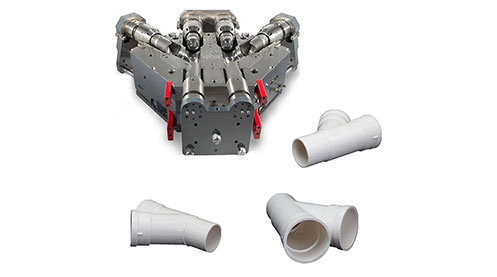

| PVC Pipe Fitting Mould | PVC Pipe Fitting is playing an important role in the pipeline systems, they are used for connection, control, direction change, diversion, sealing,... | |

| Car Light Mould | Car lights are mainly used for lighting, which can be said to be the eyes of cars. Car lights are the collective name for all car lighting systems.... | |

| Industrial Plastic Injection Mold | The injection moldingpart is replacing metal products in many fields of industrial applications to meet the requirement of lightweight industrial e... | |

| Home Appliance Mould | GV Mold has rich experience in home appliance molds (such as television, refrigerators, fans, washing machines, air conditioners, and various smart... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |