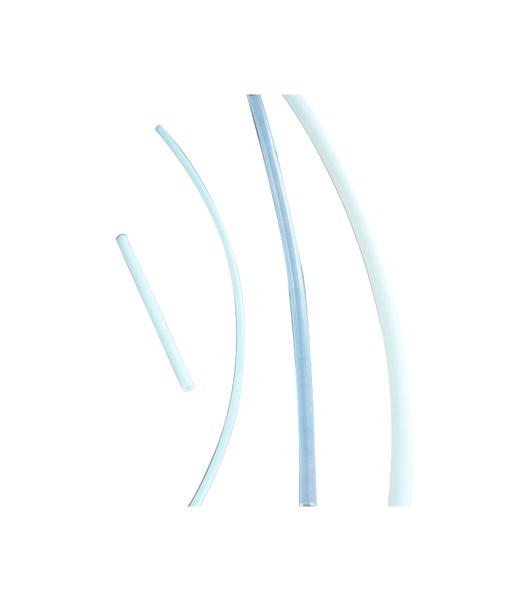

PTFE Extruded Tube

PTFE Extruded Tube

Polytetrafluoroethylene extrusion tube process.

mixing: through the mixing machine to polytetrafluoroethylene powder and extruder mix.

storage: storage at 25℃ for 24 hours.

extrusion molding: extrusion molding through the extruder.

sintering: the product into the sintering furnace for sintering.

cooling: after sintering cooling.

The polytetrafluoroethylene pipe produced by extrusion process solves the problem of poor shrinkage of polytetrafluoroethylene pipe under heat, which can not effectively improve the corrosion resistance, electrical insulation and anti-viscosity of the workpiece.

Specification of theExtruded PTFETube

|

Product name |

Speciations(mm) |

Remarks |

||

|

Diameter |

Length |

|||

|

PTFE pipe |

Molded tube |

Outer: 20-600 |

100-250 |

|

|

Hydraulic tube |

Outer: 50-300 |

500-1000 |

Diameter needs machine processing |

|

|

Extruded tube |

Outer: 30-200 |

<2000 |

the length can be customized as customer's requirement |

|

The Technical Indexes of the PTFE Extruded Tube

|

Properties |

The implementation of standards |

The technical performance index |

Remarks |

||

|

The proportion of |

Tensile strength(Mpa) |

Crack elongation(%) |

|||

|

Molded rods |

ZBG33003 SFB-1 |

≥14 |

≥140 |

QB/T 3626-1999 Light industry standard |

|

|

Molded pipe |

Company standard |

≥15 |

≥150 |

||

|

Hydraulic rod/tube |

Company standard |

≥14 |

≥150 |

||

|

Extrusion rods/tube |

Company standard |

≥15 |

≥150 |

||

Usage of Extruded PTFETubing

Mixing: through the mixing machine to polytetrafluoroethylene powder and extruder mix.

Storage: storage at 25℃ for 24 hours.

Extrusion molding: extrusion molding through the extruder.

Sintering: the product into the sintering furnace for sintering.

Cooling: after sintering cooling.

The polytetrafluoroethylene pipe produced by extrusion process solves the problem of poor shrinkage of polytetrafluoroethylene pipe under heat, which can not effectively improve the corrosion resistance, electrical insulation and anti-viscosity of the workpiece.

If you want to know more kinds of plastic industrial products, please visit our website.

As a ptfe product supplier, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| PTFE Rods/Bars | PTFE (polytetrafluoroethylene) rods/bars are widely used in industries such as engineering, electronics, and chemical processing, where their excep... | |

| Glass Filled PTFE Products | Glass Filled PTFE Gaskets PTFE filled products by PTFE resin filler, after mixing, pressing and sintering after secondary processing. This product... | |

| PTFE Slide Plate | A PTFE slide plateis a specialized component used in structural and mechanical applications. It consists of a flat plate made of polytetrafluoroeth... | |

| PTFE Molded Tube | PTFE Molded Tube PTFE rods and tubes are sintered with PTFE suspension resin after moulding or hydraulic pressing, or extruded with PTFE presinter... | |

| Silicone Rubber Products | Silicone rubber is known for its excellent temperature resistance, with the ability to withstand extreme heat and cold without losing its physical ... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |