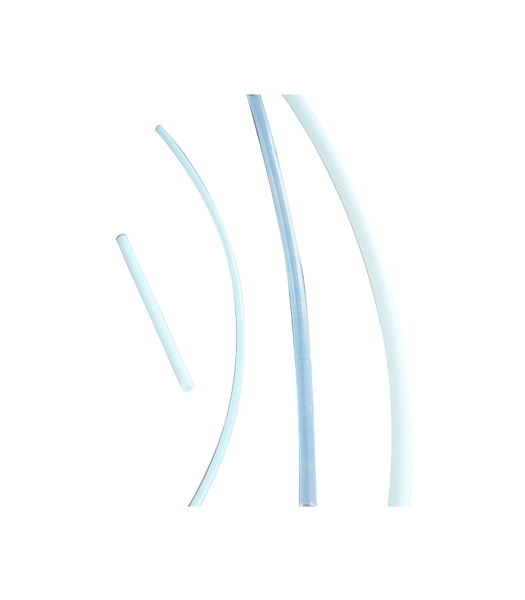

PTFE Corrugated Tube

The process is to make corrugated PTFEtubeat a certain speed through a temperature of 270℃ ~ 280℃ continuous forward rotation mold. It has all the excellent performance of PTFE but also has the characteristics of flexural, mainly used for strong corrosion resistance and high temperature resistance equipment soft connection dislocation connection, snake pipe, pump engine and other shock parts of the import and export pipe.

PTFE bellows and stainless steel metal hose have similar functions, fine appearance, no mechanical impurities, high strength, excellent chemical stability, corrosion resistance, sealing, self-lubricating non-viscosity, electrical insulation and excellent aging resistance, can be used in -60 ~ 250℃ for a long time, has reliable and excellent corrosion resistance, used for conveying strong corrosive medium under high temperature. Widely used in chemical industry, machinery, electronics, electrical appliances, military, aerospace, pipeline, petroleum, spinning machine, electrical insulation, environmental protection and other economic fields.

The Technical Indexes of PTFE Corrugated Tube

|

Length |

Wall thickness(mm) |

OD(mm) |

ID(mm) |

|

1-5 m or customized |

1 1.5 2 or customized |

12-24 mm or customized |

10-20 mm or customized |

Note: If the customer has special requirements for performance indicators, the parties shall decide through negotiation.

Feature of PTFE PlasticCorrugated Tube

Operating temperature: -200 degrees to 260 degrees.

Workability: flanged.

High transparency: Low refractive index in all plastics.

Aging resistance: can be exposed to ozone, sunlight for a long time, no aging.

Corrosion resistance: Can withstand all strong acids, strong oxidants, strong reducing agents and various organic solvents except molten alkali metals, fluorinated media and above 300°.

As one of ptfe products manufacturers, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| PTFE Braided Packing | PTFE braided packingis a new type of sealing packing with desperse Teflon tape or tensile belt after the woven. The graphited PTFE packinghas excel... | |

| PTFE Corrugated Tube | The process is to make PTFE thin-walled tube at a certain speed through a temperature of 270℃ ~ 280℃ continuous forward rotation mold. It has all t... | |

| PTFE Tube/Pipe | PTFE tubes/ pipes from PTFE tube/ pipe supplier are made from polytetrafluoroethylene resin, a synthetic polymer that is highly resistant to heat, ... | |

| PTFE Extruded Tube | Extruded PTFE tubeis frequently employed when a uniform wall thickness is required throughout the entire length of the tube. The polytetrafluoroeth... | |

| PTFE Corrugated Tube | The process is to make corrugated PTFEtubeat a certain speed through a temperature of 270℃ ~ 280℃ continuous forward rotation mold. It has all the ... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |