PP-R/PE-RT Pipe Production Lin

Application:

PP pipe extruder/PE-RT Plastic pipes are newly-developed environment-friendly products. They have the advantages of toxic-free, rust-free, filth-free, high-temperature tolerance, heat preservation, easy installation, reasonable price and etc, which already been widely used in hot & cold water for residence.

Equipment Composition:

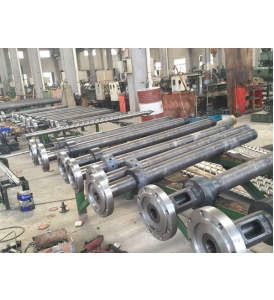

High-efficiency Single Screw Extruder →Single Screw Co-extruder →PP-R/PE-RT Pipe Mould → Vacuum Calibration Tank →Spraying Cooling Tank → Caterpillar Hauler → Cutter → Stacker.

Features of ppr pipe production line

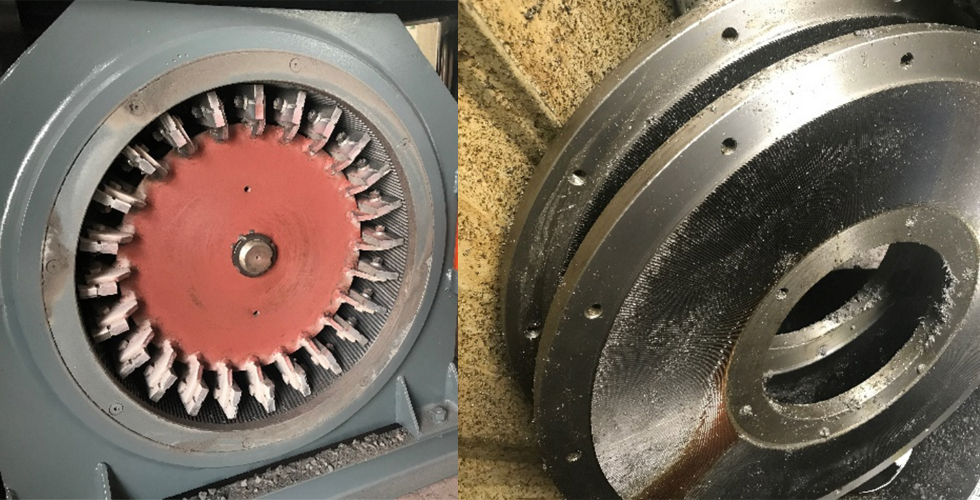

Screws adopt latest foreign technology, delivering high capacity, good plasticity. Final pipe products have high pressure resistance level.

Basket-type die head ensures stable performance during high-speed production.

Entire production line can be controlled by PLC.

Fly cutter is available to further improve high-speed production stability and save space.

Properties of PP-R/PE-RT Pipe Production Line and its Applications in Plumbing and Heating

PP-R and PE-RT pipes produced from the PP-R/PE-RT Pipe Production Line have several unique properties that make them ideal for plumbing and heating applications. Both materials have excellent thermal and chemical resistance, making them ideal for use in hot and cold potable water systems, heating systems, air conditioning systems, and underfloor heating applications. The pipes have a smooth interior surface, reducing friction losses and providing better hydraulic performance. Additionally, the pipes are lightweight and easy to install, reducing labor and installation costs. The durable and corrosion-resistant properties of these pipes provide long-term performance and reliability, essential for plumbing and heating systems.

Material Selection for PP-R/PE-RT Pipe Production Line

The strong resilience of ppr pipe making machine(Polypropylene Random Copolymer) and PE-RT (Polyethylene Raised Temperature) pipes against high temperatures and pressure, corrosion, and erosion makes them preferred options for plumbing and heating systems. Chemical, physical, and mechanical qualities must all be taken into account when choosing the materials that will be used to make these pipes. In general, high-quality resins with UV stability, such polypropylene, ethylene, and butene, are the primary ingredients utilized in the manufacturing process for PP-R/PE-RT pipes. These materials must have the requisite mechanical qualities, such as stiffness, impact resistance, and elongation at break. These requirements include the needed pipe diameter, thickness, and length as well as the intended purpose. The materials should be of good quality, devoid of contaminants, and in compliance with industry requirements, according to the manufacturing line.

There are many plastic processing machine manufacturers, but we are one of the best choices for you.

Send product request

Other supplier products

| Plastic Pulverizer Machine | MF series plastic grinder pulverizer machineis a prefect machine for processing and grinding thermoplastics material, such as PVC, PE, PP, EVA, PLA... | |

| Plastic Crusher | plastic crusher/crushing machine/crusher machinery adopts imported high-quality tool steel, special cutting-tool. The installation of the cutting... | |

| PP/PLA Drinking Straw Making Machine | YC-011 series line is mainly composed of Extruder, water cooling tank, tracking&cutting machine and Straw collection machines. With a variety o... | |

| PP-R/PE-RT Pipe Production Lin | Application: PP pipe extruder/PE-RT Plastic pipes are newly-developed environment-friendly products. They have the advantages of toxic-free, rust-... | |

| SJ Single Screw Extruder | Single screw extruder definition SJ single screw machineis a type of extrusion machine used in the plastic processing industry for forming and sha... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |