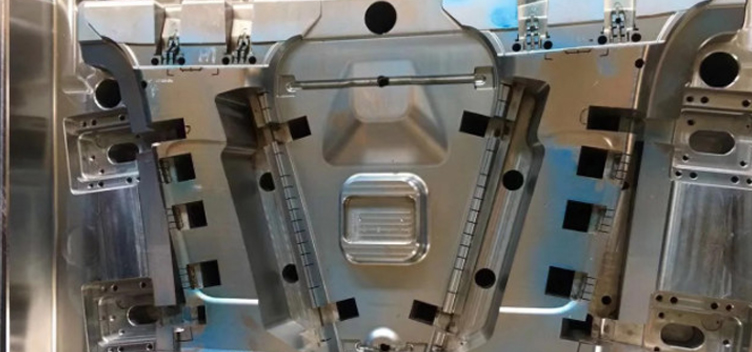

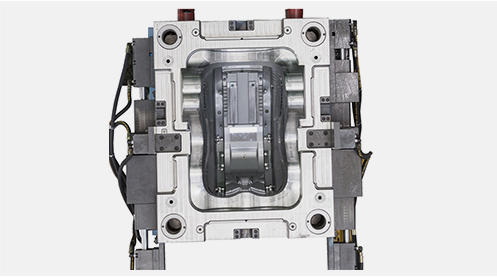

Home Appliance Mould

GV Mold has rich experience in home appliance molds (such as television, refrigerators, fans, washing machines, air conditioners, and various smart home appliances). We can provide turnkey solutions for high-precision houseware moulds according to customers' ideas, from raw material selection advice, product design optimization, mold flow analysis, mold manufacturing, mold design improvement to plastic parts production, assembly, packaging, delivery.

Home Appliance MouldTypes

LCD TV Mould

We can see many different kinds of TV LCD screen frames from different TV manufacturers. It seems like a computer screen frame, their structure is similar. The TV screen frame is a rectangular plastic frame that is assembly on the LCD screen. Usually, it has a stand base on the bottom to support the screen and the frame.

Fan Mold

Green Vitality is a professional Plastic fan blade mold, custom fans moulding services Supplier. We have done different series of plastic fan molds. However, no matter the shape of the plastic fan blade, the most important requirement is to maintain balance. Fan products are generally in a high-speed rotation state when working.

Refrigerator Drawer Mold

Green Vitality Industry has rich experience in making transparent refrigerator drawer injection molds and mirror polishing molds, high quality with durable mold lifetime, easy to maintain, to meet all customers' requirements.

Home Appliance MouldProcess

Before making home injection mold, household injection mould, we usually verify the plastic product & mold in the following steps. In this way, we can speed up product development, effectively control mold costs, reduce mold repair costs in the manufacture stage, and fully verify product performance as much as possible to save time and cost.

PROTOTYPE SAMPLE

The prototype part is not only visible but also can be assembled. it can intuitively reflect whether the structure is reasonable or not, and the difficulty of installation. It is convenient to detect and solve problems in the early stage. Usually made by rapid prototyping parts, CNC processed rapid prototypes, and 3D printing within 1 week.

SOFT TOOLING

After the prototype parts verification, we will improve the problems found,and then carry out small batch assembly test. In addition, in order to carry out more sufficient verification and avoid the risk of mold scrap, usually at this stage, we will first develop a lower cost soft mold to verify the mold structure and mold feasibility, and the material and structure of the parts are the same to mass-produced parts. Soft molds can typically produce no more than 10,000 shots.

PRODUCTION TOOLING

After the home appliance partshave been fully verified and approved, the official steel mold is developed. The official steel mold can produce 50000, 100000, or 300000 parts according to the different steel materials used, and select the appropriate steel material according to the planned output.

Plastic Household MouldAdvantages

Quick Response

Provide quote in 24hours with drawings and requirements if urgent.

Experienced Staff

Over 95% designers & engineers are with more than 10 years experience in plastic mold industry. and all project engineers could discuss projects in English to save communication time.

High quality control

Strictly conforms to ISO9001:2015 quality control system.

One-stop service provider

Technical support from the initial product design to the entire stage of mold making and product production and delivery.

Now the price of injection molds for saleis reasonable, if you have needs to buy plastic injection mold, please contact us.

Send product request

Other supplier products

| Auto Rear View Mirror Housing Mold | Auto Rear View Mirror HousingMold The car rearview mirror is an important part of car exterior parts, located on both sides of the car, is one o... | |

| Injection Mold & Molding Parts Solution | Injection Mold& Molding Parts Solution Green Vitality Industry is a full-service mold manufacturer specializing in plastic injectionmold desig... | |

| Keyboard Mould | Mainly electronic molds we make are electronic housing mold, electronic components mold, electronic dashboard cover mold, computer keyboard key mol... | |

| Plastic Food Container Mould | Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental pr... | |

| Car Seat Mould for Kids | Child safety mouldy car seatsare seats specially designed to protect children from injury or death in a collision. The main structure of the child ... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |