Injection Mold Design Engineering

Injection Mold Design Engineering

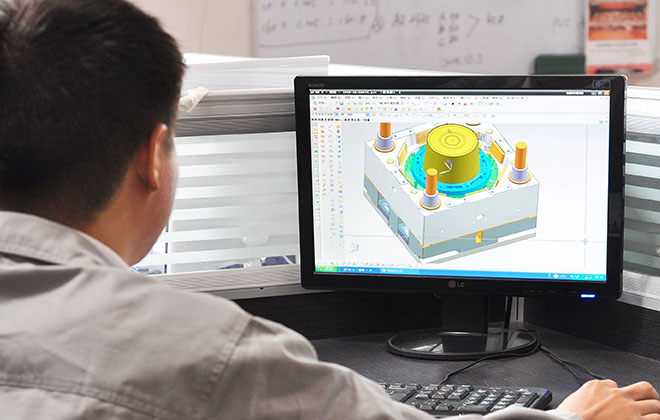

Injection mold engineeringis a procedure at the first stage of injection molding process, which develops the injection mold designs to improve the effectiveness and efficiency in injection molding. Plastic mold designtechnical team of R&D and engineers of Keyplast is diligent for every project from our clients. As a leading plastic injection mold maker in China, Keyplast could assist our clients to make 2D/3D designs per the samples or concepts and bring their ideas into reality. If any defects, our team will offer professional suggestions and take rapid modifications for every project.

Mold Design

Plastic injection molding mold designis a procedure after confirmation of product design and before molding process. In the mold industry, there's never a one-size fits for all project. For each project whether you send us a sample or a 2D file, we always work with you to make improvements for all technical drawings including 2D files, 3D files of the product. You can start from sharing important details about your project, then our designers will run an analysis on your plastic mold tooling design and make adjustments for plastic injection moulding chinaaccordingly. With correct injection molding part designs , parts can be manufactured with well consistency and high quality, but without good injection molding mold designs, you may make costly processing mistakes.

Mold-Flow Analysis

Mold flow Analysis simulates the flow of plastic materials to improve the products and plastic mould design, so to create products of high quality. Mould flow analysis could help you to have a virtual look into how the plastic materials fill the cavities of the molds. It could help to analyze the moulding process before cutting the steel, thus saving money and time.

Prototyping: 3D Printing

3D Printing is a process to produce a 3-dimensional part by using a CAD file. The objects are created layer by layer using a variety of different plastic molding materials and layer bonding techniques, with the types of FDM, SLS, SLA, PolyJet and etc. Compared to CNC process, 3d printed injection moldcould easily achieve a higher level of complexity through rapid prototyping, but 3d injection molding requires less tooling cost at lower volumes, like Multi Jet Fusion. But regarding the manufacturability, wall thickness is a key consideration to ensure parts in sound structure.

As a china plastic injection mold manufacturer, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Injection Molding Service | As a plastic injection molding service factoryand plastic injection molding service manufacturer, Keyplast has leading advantages in custom plastic... | |

| Injection Molding Materials | Common Injection Molding Materials What materials are used in injection moulding? Materials used in injection moulding generally include abs mold... | |

| Injection Mold Design Engineering | Injection mold design engineeringis a procedure at the first stage of injection molding process, which develops the injection mold designs to impro... | |

| Plastic Injection Molding | Plastic Injection Molding What is plastic small scale injection molding? Plastic Injection molding is a molding method that combines injection and... | |

| Gardening Injection Molding | Keyplast brings every concept into a reality, not only for every client, but also for our own development in all areas, especially in gardening ind... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |