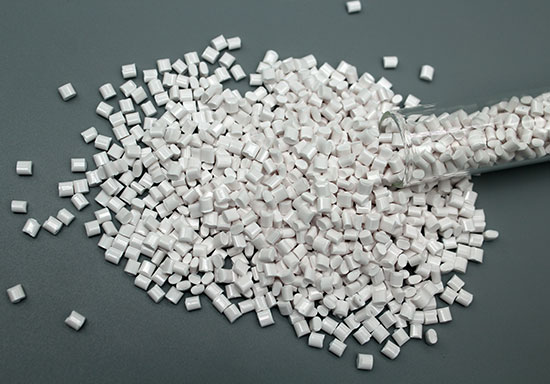

Nylon6 PA6

Other than fiber-reinforced pa6 polyamide, the unreinforced nylon type 6 produced by Anmei, one of the professional nylon 6 suppliers/manufacturers, is also divided into toughened, heat-resistant, alloy and flame-retardant modified PA6.

Nylon 6 (PA6) is made up of a group of 6 carbon atoms. PA type 6 plastichas a low melting point, a wide process temperature range, and strong impact resistance and solubility resistance. Both high tensile strength and super-high tensile strength Nylon6 (PA6) have excellent flexibility, impact resistance, low-temperature resistance, wear-resistance and dimensional stability of the pa6 6 material. PA6 flame retardant is mainly achieved by adding halogen-free flame retardant and halogen flame retardant to achieve the flame retardant effect. The physical and mechanical properties of these nylon 6 plastic materials are comparable to similar products in Europe and America. This series of halogen-free flame retardant products comply with RoHS environmental protection standards. The nylon 6 PA6price provided by Anmei is reasonable and high-quality nylon 6 plastic is available.

Types of Nylon 6 PA6 Plastic Material

The nylon 6 PA6 plastic material we offer including the following three types: high tensile strength type, heat stabilized type and nylon flame retardants. Click below to get more!

Nylon 6 PA6 impact resistance

Nylon has good impact resistance at room temperature, but the impact resistance at low temperature is not good enough. Therefore, the toughening modification of nylon is mainly to improve the impact resistance at low temperatures.Read More ·

Nylon 6 PA6 Heat Stabilized

Due to the poor thermal stability of nylon 6, after being heated or stored for a period of time, the appearance and performance of injection molding products will decrease.

Nylon 6 PA6 FR

Nylon flame retardants are divided into two categories: halogen series and halogen-free flame retardants according to whether they contain halogen.Read More·

PA6 vs PA66

The main varieties of nylon are nylon 6 (PA6) and nylon 66 (PA66), which are absolutely dominant. The pa6 and pa66 differencethe two is as follows.

Nylon PA6 is poly-caprolactam, while nylon 66 PA66 is poly-adipic acid adipamide, PA66 is 12% harder than nylon PA6. PA6's chemical and physical properties are very similar to PA66, however, it has a lower melting point and a wide range of process temperatures. Nylon 6 plastic has better impact resistance and dissolution resistance than PA66, but it is also more hygroscopic. PA66 is a semi-crystalline - crystalline material with a higher melting point, which can also maintain strong strength and stiffness at higher temperatures.

Polyamide nylon 6 has excellent thermal stability, high heat resistance; good dimensional stability; high surface quality; good anti-warping properties; PA66 has excellent wear resistance, good high impact resistance and good dimensional stability.

Nylon PA6 is generally used in automotive parts, mechanical parts, electronic and electrical products, engineering parts, etc. PA66 is more widely used in the automotive industry, instrument housings and other products that require impact resistance and high strength requirements, such as marine propellers, gears, rollers, pulleys, rollers, impellers in pump bodies, fan blades, high-pressure sealing enclosures, valve seats, gaskets, bushings, various handles, support frames, wire packages Inner layer, etc.

Drying process (If the material is sealed before processing, then there is no need to dry. If the storage container is opened, then it is recommended to dry the process in hot air at 85℃. (If the humidity is greater than 0.2%, vacuum drying at 105°C for 12 hours is also required.)

Melting temperature (230~280℃ for PA6, 250~280℃ for reinforced nylon; 260~290℃ for PA66. (275~280℃ for glass-modified products, melting temperature should be avoided higher than 300℃.)

Mold temperature (80~90℃, the mold temperature will affect the crystallinity, and the crystallinity will affect the physical properties of the product)

Injection pressure (usually at 750~1250bar, depending on the material and product design.)

Injection speed (high speed (to be slightly reduced for reinforced nylon))

Runners and gates (solidification time is very short, so the location of the gates is very important)

Introduction of Nylon PA6 halogenated & halogen-free FR plastic

Nylon flame retardants of polyamide nylon 6 are divided into two categories: halogen series and halogen-free flame retardants according to whether they contain halogen.

▲ Halogen-based flame-retardant nylon PA6 has good thermal stability and good fluidity during processing. It is mainly suitable for the production of small, thin-walled, complex-structured components, such as switches, reconnectors, and plug-ins;

▲ Halogen-free flame-retardant nylon PA6 is used in flame-retardant reinforced nylon varieties with strict environmental protection requirements. Phosphorus flame-retardant nylon has good mechanical properties and is suitable for electronic and electrical parts.

Please put forward your needs, and Anmeiengineers will deploy suitable nylon PA6 flame-retardant modified plastics according to your comprehensive index.

For more information about abs and pc material, please feel free to contact us!

Send product request

Other supplier products

| Anmei-PA6 GF for Engineering Plastics | As an engineering plastic company, Anmei focuses on the production of modified engineering plastics, among which high-performance nylon 6 engineeri... | |

| Anmei-ABS Engineering Plastic | ABS resin is a terpolymer composed of acrylonitrile, butadiene and styrene. ABS has the rigidity, chemical resistance and heat resistance of polyac... | |

| Color Masterbatch for Engineering Plastics | As one of plastic colorant suppliers, Anmei serves customers with tailored-making solutions from standard colors to customized colors and functions... | |

| PA6 GF50 (A1011J) for Engineering Plastics | PA 6 GF50is a fiber reinforced plastic made of nylon 6 resin as a base material and 50% glass fiber as a reinforcing filler, and various processing... | |

| Engineering Plastic | We are here to be your reliable partners of modified plastic. Engineering plastic is the high-performance plastic that can apply in different indu... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |